Rockwell Automation Publication 440R-UM012E-EN-P - November 2018 25

Power, Ground, and Wire Chapter 3

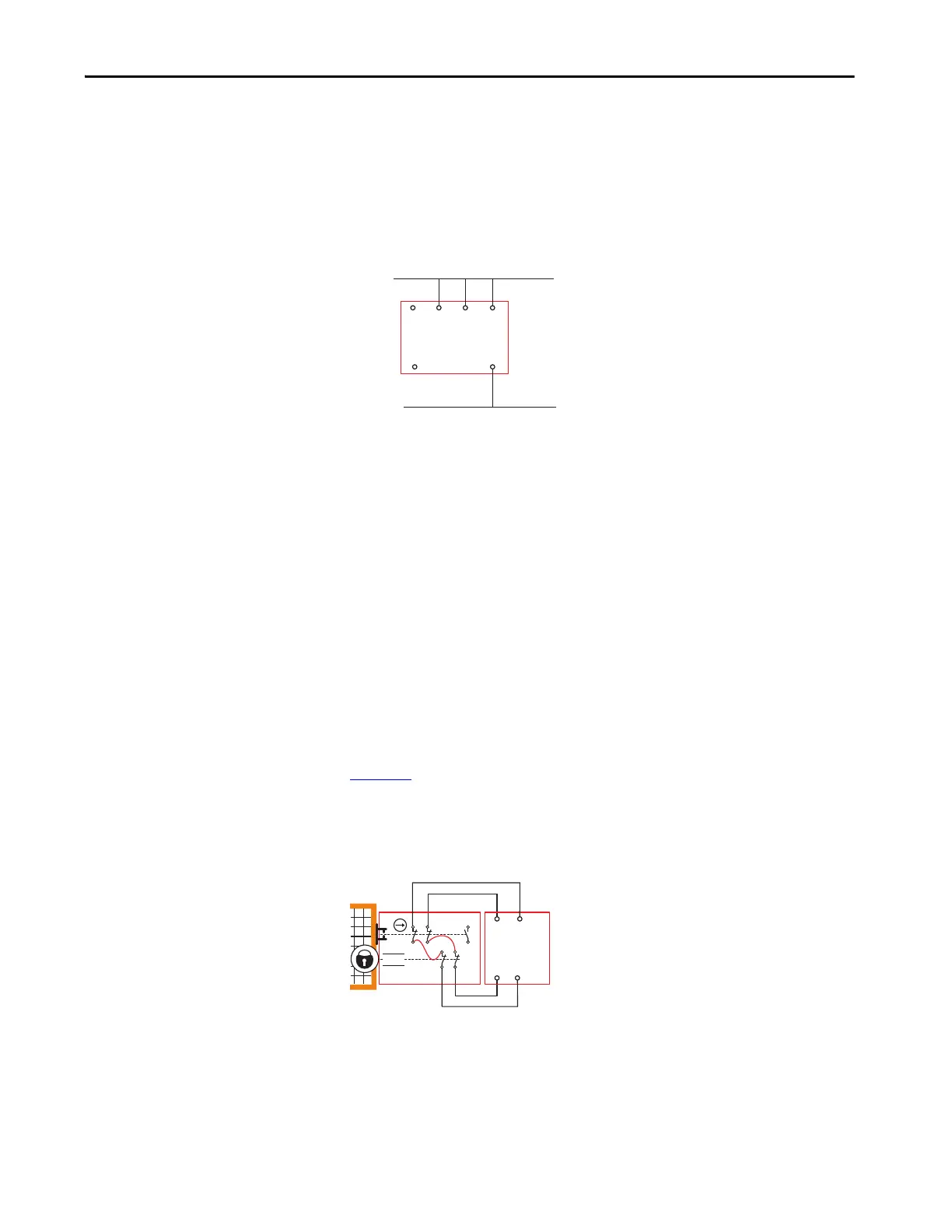

No Guard Locking

If no guard locking is required for Stop Cat 1 or SLS functions, then 51 and

L61 can be left open. The safety inputs S12 and S22 must be connected to 24V

DC. With this arrangement, the X14/X24 L11 status indicator blinks one

time during the configuration process.

Figure 17 - No Guard Locking Connections

Safety Outputs

Terminal X14 and X24 can be configured as pulse test outputs or safety

outputs. Start the configuration process from 9 to configure X14 and X24 as

pulse test outputs. Start the configuration process from 0 to configure X14 and

X24 as safety outputs.

When configured as pulse test outputs, the GLP safety relay continuously

provides 24V DC combined with short test-pulse signals on terminals X14 and

X24. This configuration is used in applications with guard locking devices that

have mechanical contacts. The purpose of the pulse testing is to test for the

following short-circuit conditions:

• Between X14 and X24

• From X14 or X24 to 24V DC

• From X14 to X24 to 24V common

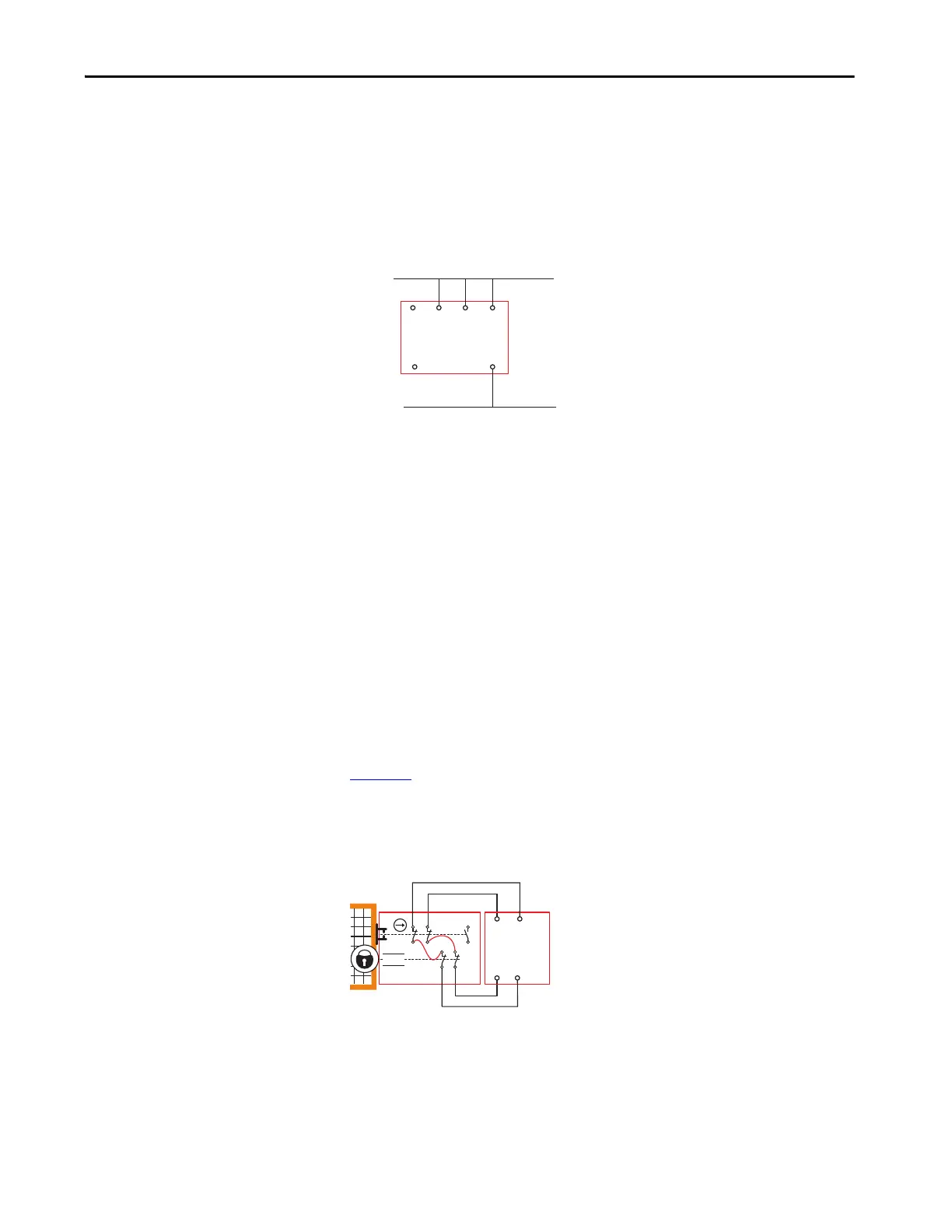

Figure 18

shows an example wiring connection of the pulse testing outputs

(X14 and X24) connected to a TLS3-GD2 guard locking switch. The output

signals are fed through the mechanical contacts and back to the safety inputs

(S12 and S22) of the GLP safety relay.

Figure 18 - Pulse Test Output Connections

When configured as safety outputs, terminals X14 and X24 are safety outputs.

The safety outputs are only turned ON when safe conditions are met. When

configured as safety outputs, these terminals test for short circuits when they

are turned ON. The safety outputs are commonly referred to as OSSD

outputs.

GLP

L61

51 A1

A2

+24V DC

24V DC Com

S22S12

Safety

Gate

12

22 34

11 21

33

A1

A2

42

41

52

51

X14

GLP

S12

TLS3-GD2

S22

X24

Loading...

Loading...