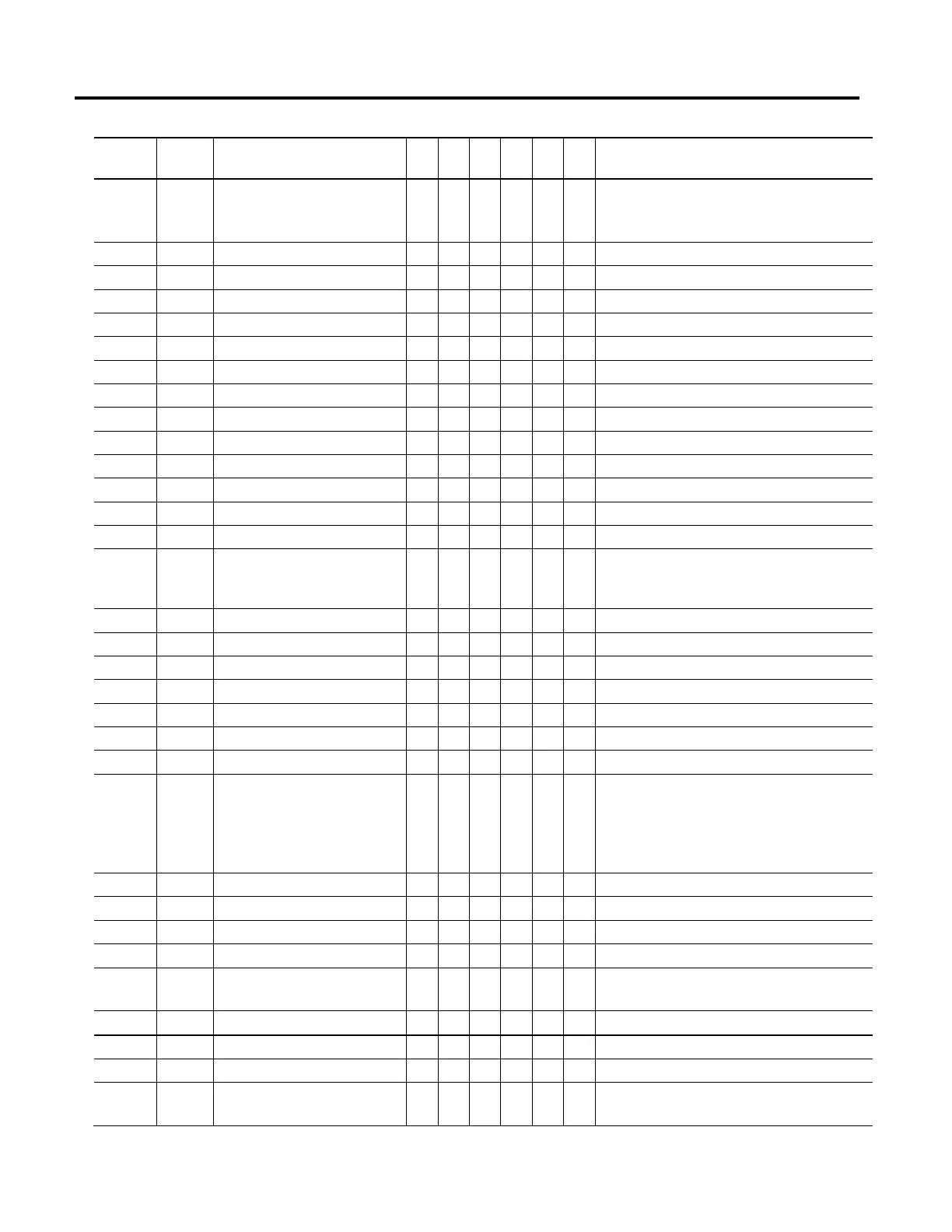

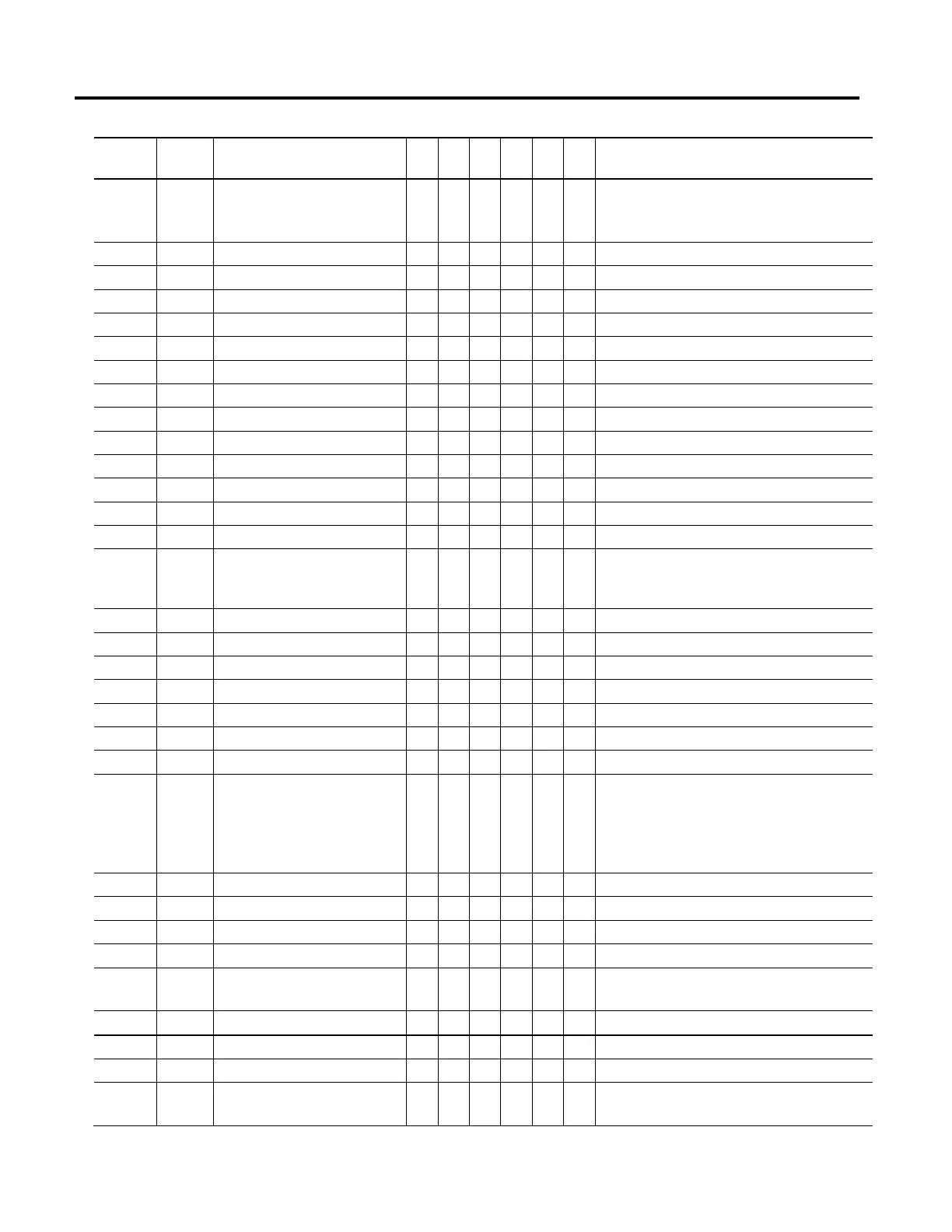

Interpret the Attribute Tables

126 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

ID Access

Rule

Attribute B E F P V T Conditional Implementation

570 Set Frequency Control Method

- R - - - O-Enum

128 = Fan/Pump Volts/Hertz (Y) 129 = Sensorless Vector (Y)

130 = Sensorless Vector Economy (N)

498 Set Friction Compensation Sliding

- - Y Y Y4

499 Set Friction Compensation Static

- - Y Y4 Y4

500 Set Friction Compensation Viscous

- - Y Y Y4

826/421 Set Friction Compensation Window

- - Y - -

981/243 Get Guard Faults

- Y Y Y Y

980/242 Get Guard Status

- Y Y Y Y

280 Set Home Torque Threshold

- - N N - Vxx

281 Set Home Torque Time

- - N N - Vxx

1349 Set Induction Motor Magnetization Reactance

- N N N N Ind Motor only

1352 Set Induction Motor Rated Slip Speed

- Y N N N Ind Motor only

1351 Set Induction Motor Rotor Leakage Reactance

- Y Y Y Y Ind Motor only, V26/V27

1350 Set Induction Motor Rotor Resistance

- N N N N Ind Motor only

1348 Set Induction Motor Stator Leakage Reactance

- Y Y Y Y Ind Motor only, V26/V27

647 Set Inverter Overload Action

- Y Y Y Y O-Enum

1 = Current Foldback (Y) 128 = Reduce PWM Rate (N) 129 =

PWM Foldback (N)

699 Set Inverter Thermal Overload User Limit

- Y Y Y Y

1338 Set Linear Motor Damping Coefficient

- N N N N Linear Motor only

2313 Set Linear Motor Integral Limit Switch

- N N N N Linear Motor only

1336 Set Linear Motor Mass

- N Y Y Y Linear Motor only

1337 Set Linear Motor Max Speed

- N Y Y Y Linear Motor only

801 Get Load Observer Acceleration Estimate

- - Y Y Y

806 Set Load Observer Bandwidth

- - Y Y Y

805 Set Load Observer Configuration

- - Y Y Y O-Enum

1 = Load Observer Only (Y)

2 = Load Observer with Velocity Estimate (Y) 3 = Velocity

Estimate Only (Y)

4 = Acceleration Feedback (N)

809 Set Load Observer Feedback Gain

- - Y Y Y

807 Set Load Observer Integrator Bandwidth

- - Y Y Y

802 Get Load Observer Torque Estimate

- - Y Y Y

1370 Set Load Type

N N N N N DScale

750 Set Local Control N N N N N N O-Enum

1 = Conditionally Allowed (N) 2 = Allowed (N)

614 Set Mechanical Brake Control

- Y Y Y Y

616 Set Mechanical Brake Engage Delay

- Y Y Y Y

615 Set Mechanical Brake Release Delay

- Y Y Y Y

45 Set Motion Scaling Configuration

R R R R R O-Enum

1 = Drive Scaling (N)

Loading...

Loading...