Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018 421

where the safety function is executed, be it in the Safety Controller, or the drive's

Safety Core.

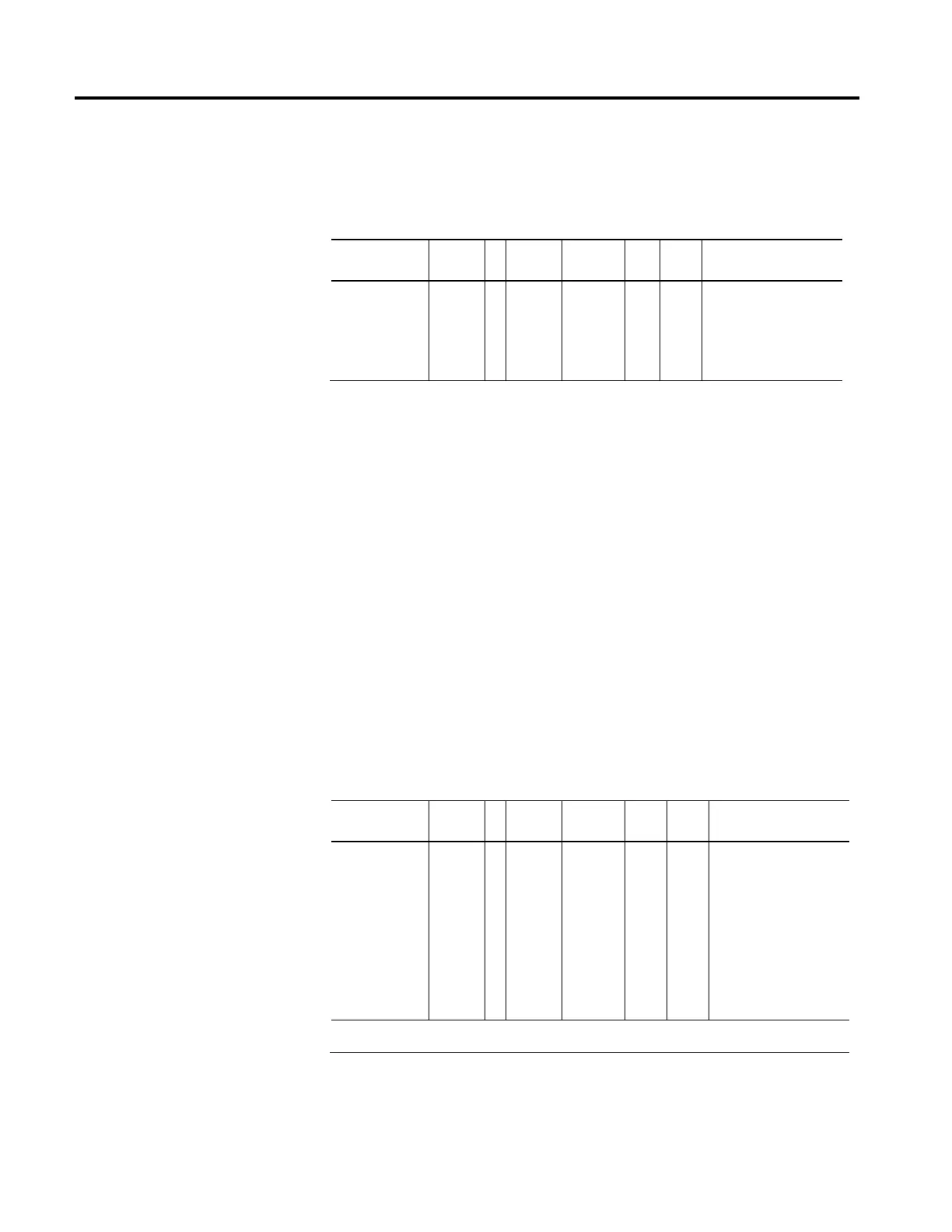

Axis Safety Faults - RA

Usage Access T

Data

Type

Default Min Max Semantics of Values

Optional - DE

Safety only

Get/GSV T DWORD - - - Bitmap:

0 = (reserved)

1 = Safety Feedback Interface

(SFX) Fault

2...31 = (reserved)

The Axis Safety Faults - RA attribute is a collection of bits indicating the safety

fault status of the axis associated with Rockwell Automation specific safety

functionality as reported by the embedded Safety Core of the device. When a

safety fault condition occurs, the Safety Core forces the axis into a Safe State and

the corresponding bit is set in the Axis Safety Faults RA attribute. An active safety

fault bit remains latched even if the underlying safety fault condition is cleared by

the Safety Core. A Fault Reset Request to the associated axis clears the safety fault

bits, but the bits immediately set again if the underlying safety fault condition is

still present.

For Rockwell Automation safety drive devices, the safety fault status data from the

drive's Safety Core may include safety faults from the Safety Controller through

the Pass Thru data included in the Safety Output assembly. This allows the Axis

Safety Faults RA attribute to reflect safety function fault conditions regardless of

where the safety function is executed, be it in the Safety Controller, or the drive's

Safety Core.

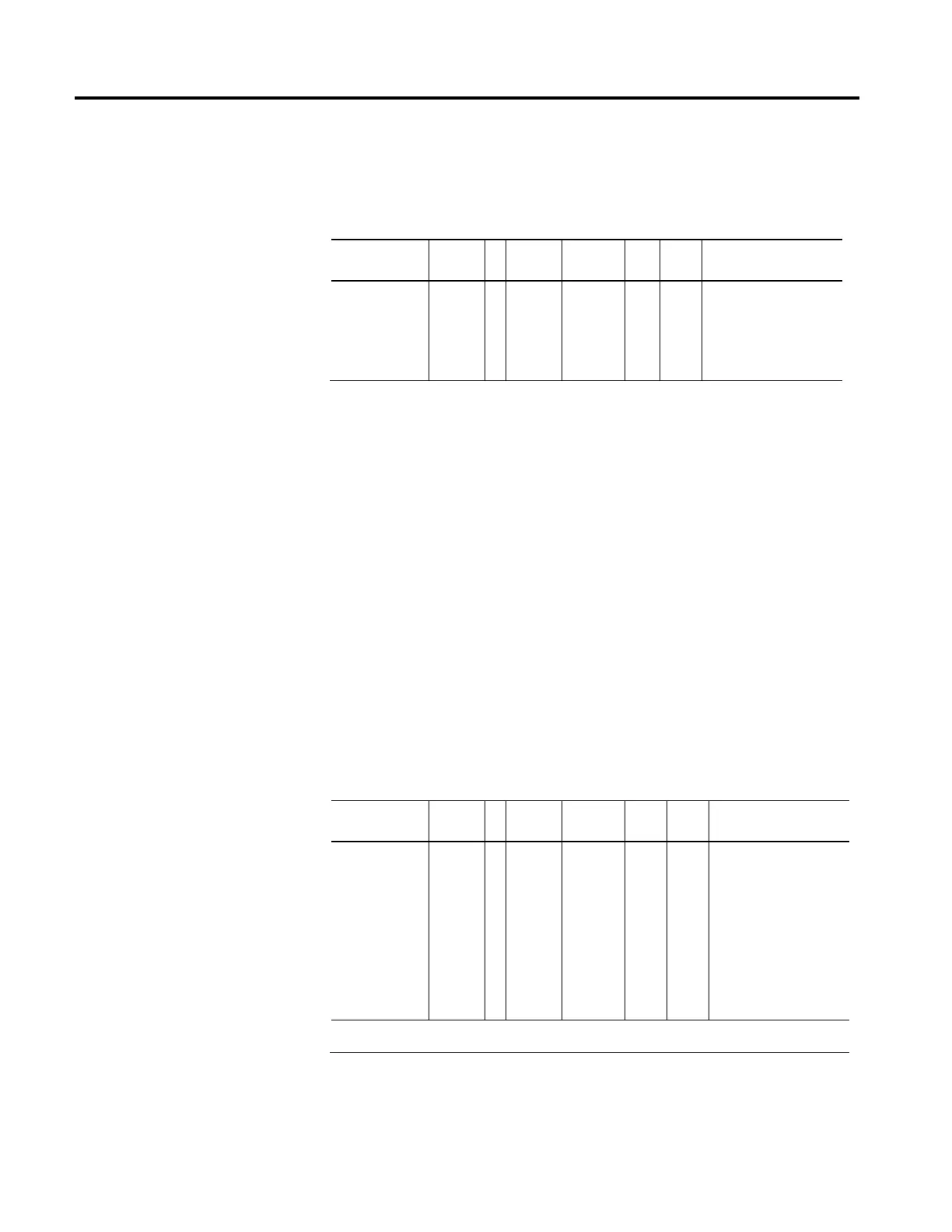

Safe Torque Off Action

Usage Access T Data

Type

Default Min Max Semantics of Values

Optional - D

Safety Only

Set/

SSV#

USINT FD

1 for C

0 for F

- - Enumeration:

0 = Disable and Coast

1 = Current Decel and Disable

2 = Ramped Decel and

Disable

3-127 = (reserved)

128-255 = (vendor specific)

128 = DC Injection Brake

129 = AC Injection Brake

# Indicates the attribute cannot be set while the tracking command (Tracking Command bit in CIP Axis Status is true).

When the drive detects a Safe Torque Off (STO) Active condition that was not

initiated by a Safe Stop 1 (SS1) Active condition, as reported by the embedded

Safety Core through the Axis Safety Status attribute, and the Safe Torque Off

Loading...

Loading...