Service Brake See page 49 for brake schematic.

Inspect the Service Brake DAILY. A daily Service Brake inspection performed with an empty buggy

traveling at full speed must demonstrate that when full foot pressure (125 LB.) is applied to the brake

pedal both brakes engage equally, the pedal is level with the top of the operator’s platform, the buggy

stops in 6-8’ of travel and the engine stalls.

3.1 - Brake Service

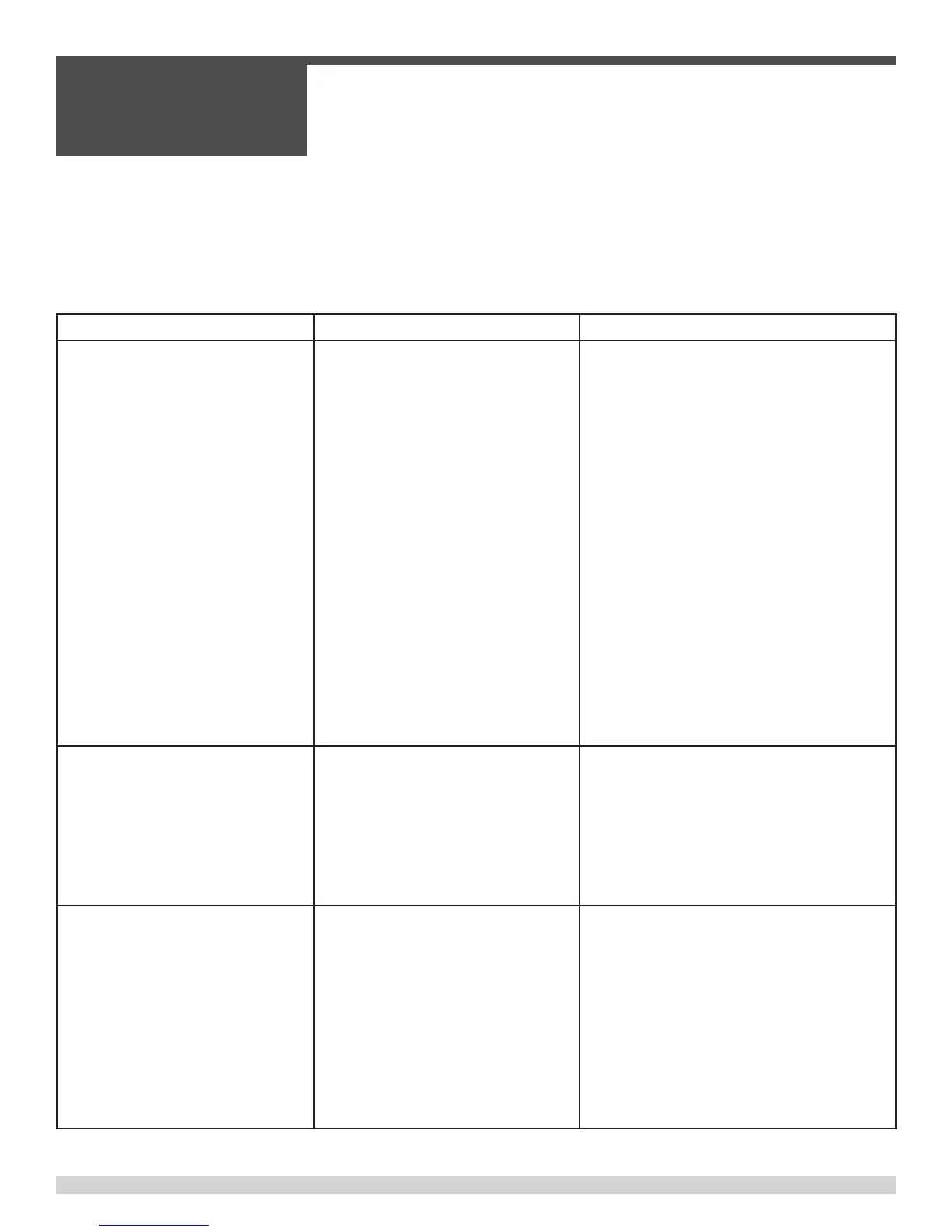

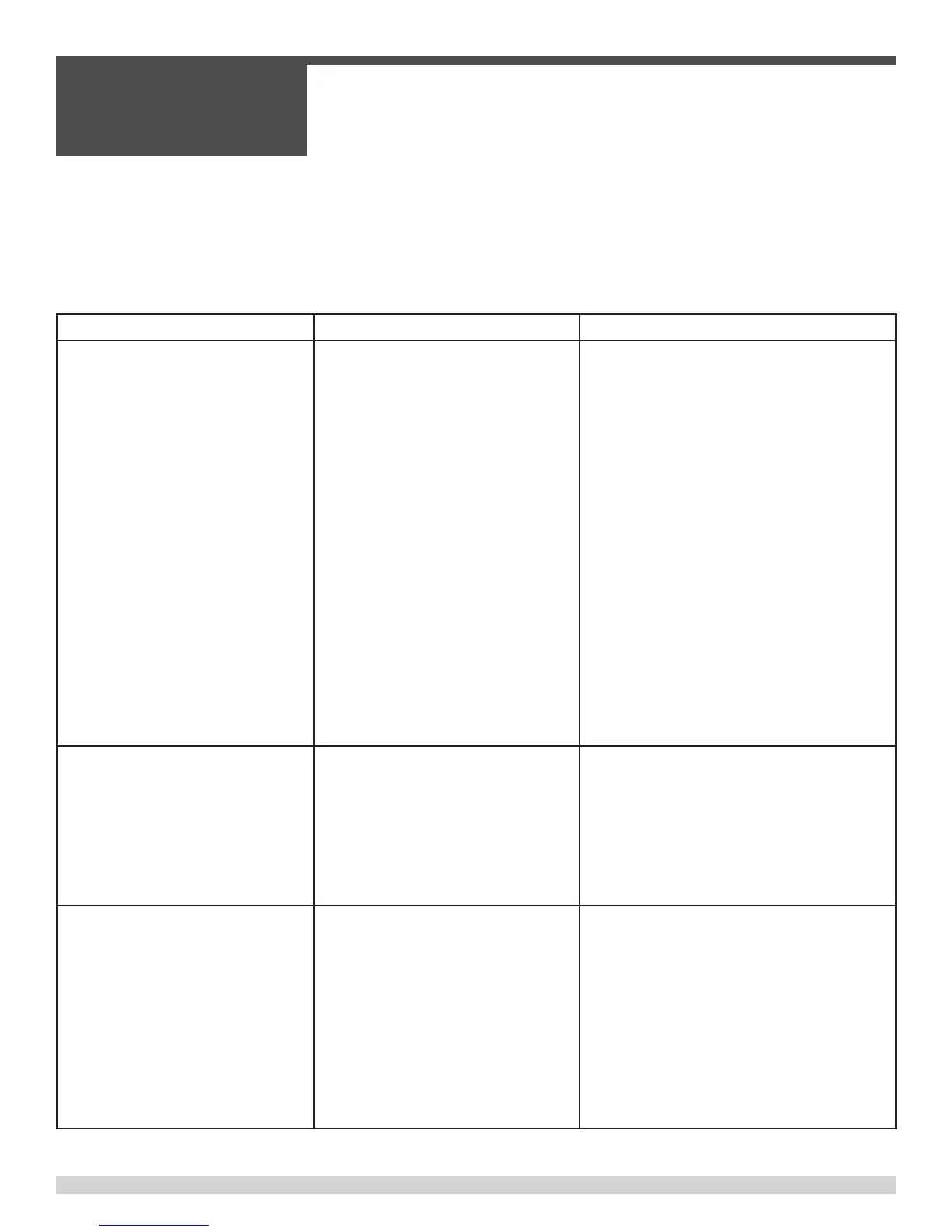

Brake Operational Problem Adjustment/Repair Required Adjustment/Repair Procedure

1) Brake pedal (44) travels

below operator’s platform

before brake engages.

Tighten brake bands.

1) Turn nut (16) clockwise. Use 3/4”

deep well socket. Turn nuts for both

brakes in increments of ¼ turn until

brake pedal activates brake at the

top of operator’s platform. Verify

both brakes engage at the same

time by running buggy, applying

brake and having an observer verify

both brakes lock up together.

2) If after making adjustment in

#1 above, the pedal is still below

operator’s platform when the ser-

vice brake is engaged, shorten the

distance of the (2) clevis’, item 34.

Reattach clevis pins with NEW 1/8”

x 3/4” long cotter pins.

2) One brake engages before

other brake.

Tighten brake band on brake

that engages late.

Turn nut (16) clockwise on brake

that engages late in increments of

¼ turn until both brakes activate

together. Verify brake operation with

an observer (see 1 above).

3) Brakes screech when

applied.

1) Clean concrete/dirt /oil

accumulation away from brake

bands.

2) Replace worn brake

bands(s) (brass rivets are

contacting brake drum and/

or brake lining worn less than

1/8” thick).

Remove four (4) front wheels. Re-

move two (2) brake covers and

brake band(s) and clean. Replace

brake bands if required and readjust

brakes per above.

SECTION 3

SERVICE

055838 Page 46

Loading...

Loading...