3.6.8. Hydraulic tank oil level check

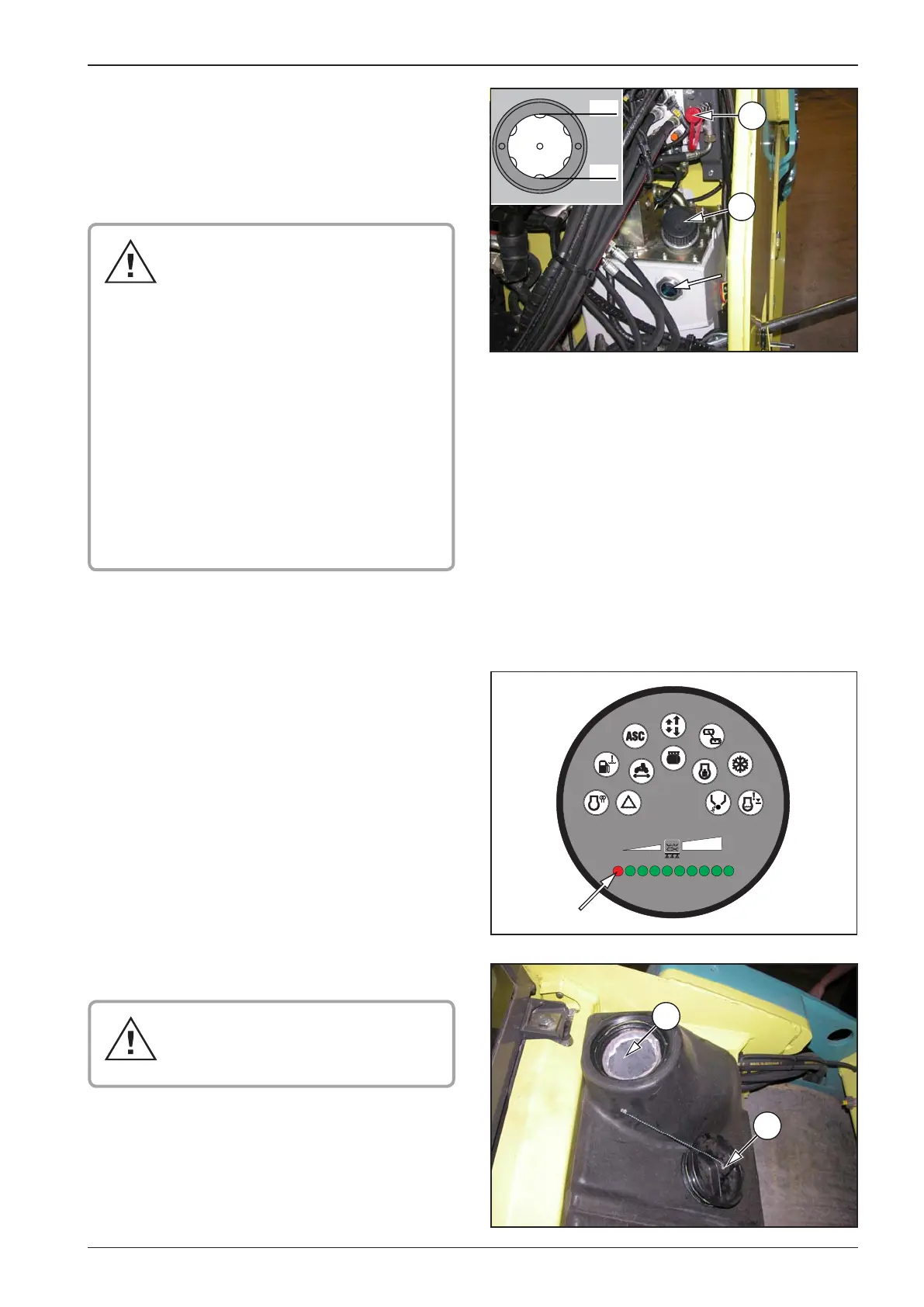

Lift the bonnet.•

Check oil level in oil gauge.•

Fill up oil via the lling device using quick-coupling (1), pro-•

ceed as per Section 3.6.28.

Tank ller neck cap (2) has been sealed.

If this seal is damaged during guarantee

period, then the Machine guarantee will

terminate.

Conduct this lling method as emer-

gency one – not recommended by

manufacturer!

Oil level shall always be visible in oil

gauge!

Rell required oil according to the

Section 3.2.4.

Upon higher loss of oil, nd out the

cause of hydraulic system leaking (leaks

through hose screw joints, screwed t-

ting of hydroelectric generators or of

hydraulic motors, etc.), and repair the

defects.

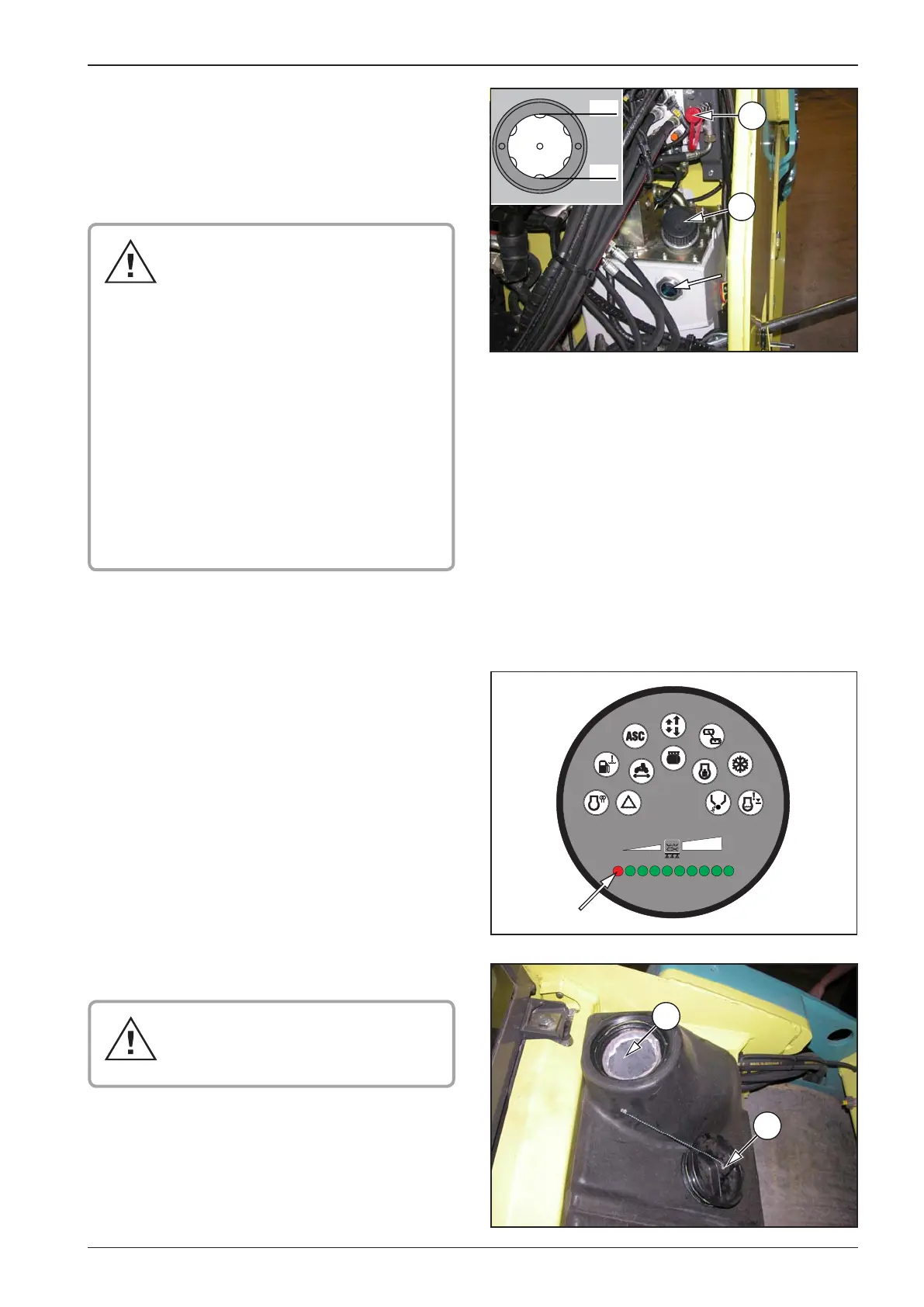

3.6.9. Water tank relling

Check water amount on the RH cluster. It is signalled by •

LEDs, and in case of lack of water, please rell.

Minimal amount of water is signalled by red LED ashing.•

Perform the following before engine is started.•

Before winter period, drain water from

the water tank and sprinkling system!

Proceed according to Section 3.6.34.

Open the cap (1) and rell with clean water via the strainer (2).

Loading...

Loading...