143AV 70 X

MAINTENANCE MANUAL

3.6.36. Machine cleaning

When the work is completed clean the Machine to get rid of •

major impurities.

Carry out overall cleaning on regular basis, at least once per •

week. Total cleaning must be done daily if working on cohe-

sive soils, cement or lime stabilizations.

Disconnect the disconnector.

Carry out the work with the engine

stopped.

NEVER use aggressive or easily ignitable

cleaners (e.g. petrol or easily or ash

fuels).

Before pressure cleaning with water or

steam, please blind all the ports into

which a cleaner might penetrate (e.g.

engine inlet port). With the Machine

cleaned remove these blinds.

Do NOT expose electric parts or insula-

tion material to direct water or steam

streams. Always cover these materials

(alternator’s inner space, etc.).

Clean the Machine at a workplace

equipped with cleaner collection sys-

tem so to avoid soil or water recourse

contaminations!

NEVER use banned cleaners!

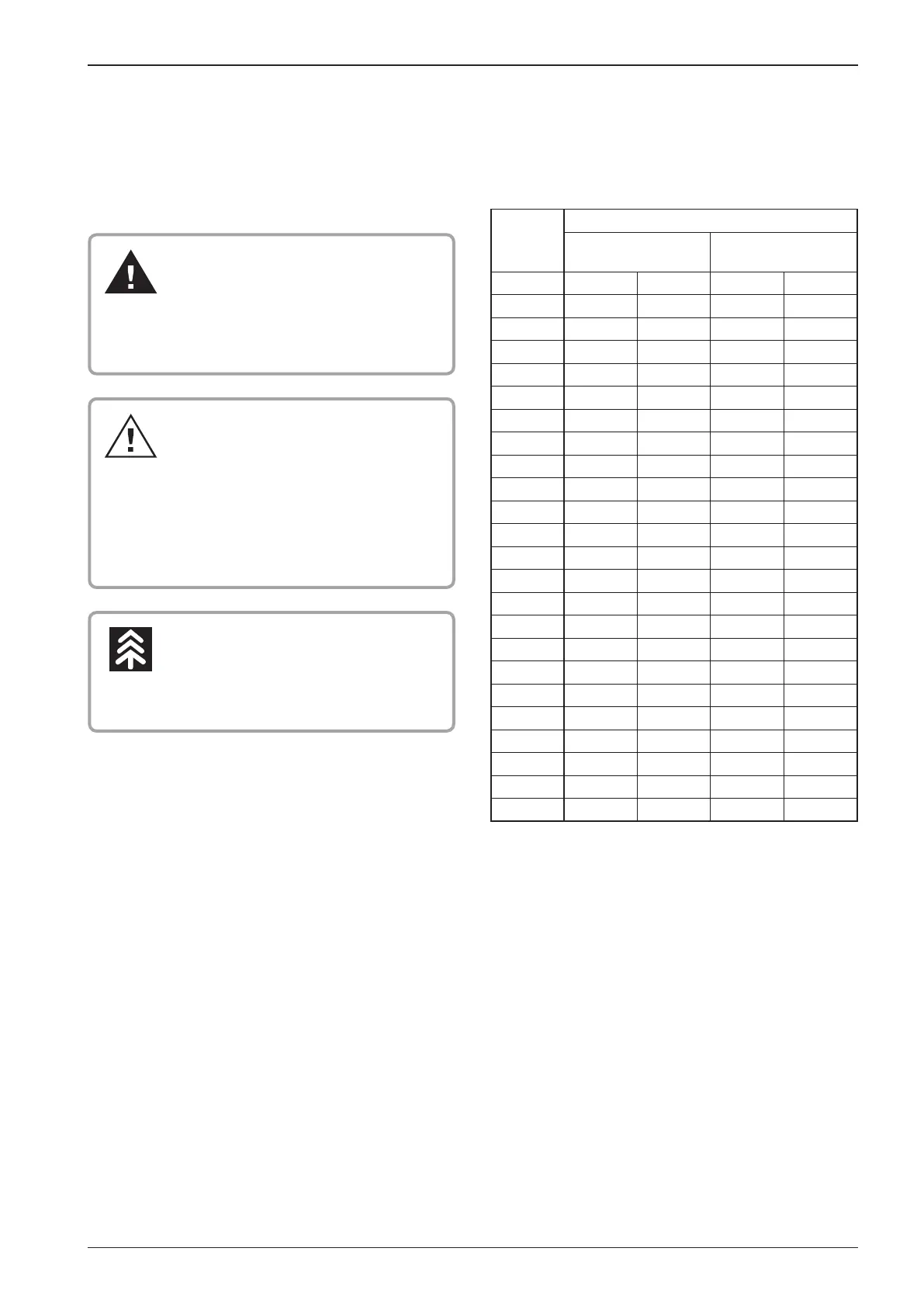

3.6.37. Check the tightening of bolted

connections

Conrm regularly that no loosening of bolted connections •

has occurred.

Use the torque spanners to do the tightening.•

TIGHTENING MOMENT

For the screws

8,8 (8G)

For the screws

10,9 (10K)

Worm Nm lb-ft Nm lb-ft

M6 10 7,4 14 10,3

M8 24 25,0 34 25,0

M8x1 19 14,0 27 19,9

M10 48 35,4 67 49,4

M10x1,25 38 28,0 54 39,8

M12 83 61,2 117 86,2

M12x1,25 66 48,7 94 69,3

M14 132 97,3 185 136,4

M14x1,5 106 78,2 148 109,1

M16 200 147,5 285 210,2

M16x1,5 160 118,0 228 168,1

M18 275 202,8 390 287,6

M18x1,5 220 162,2 312 230,1

M20 390 287,6 550 405,6

M20x1,5 312 230,1 440 324,5

M22 530 390,9 745 549,4

M22x1,5 425 313,4 590 435,1

M24 675 497,8 950 700,6

M24x2 540 398,2 760 560,5

M27 995 733,8 1400 1032,5

M27x2 795 586,3 1120 826,0

M30 1350 995,7 1900 1401,3

M30x2 1080 796,5 1520 1121,0

The gures given in the chart are torques at dry thread (with

coecient of friction = 0,14). These gures do not apply to a lu-

bricated thread.

Loading...

Loading...