3.6. Lubrication and Maintenance Operations

Drain oil when hot – best upon operation

completion.

Use original lters only.

Use recommended oil under Section

3.2.1, only.

To not overtighten the lter, its thread

and gasket may get damaged.

Check the tightness.

Collect the oil drained, do not let oil soak

into soil.

Dispose of oil compliant to regulations.

Store used lters in a separate container

and handle them so these do not pollute

the environment.

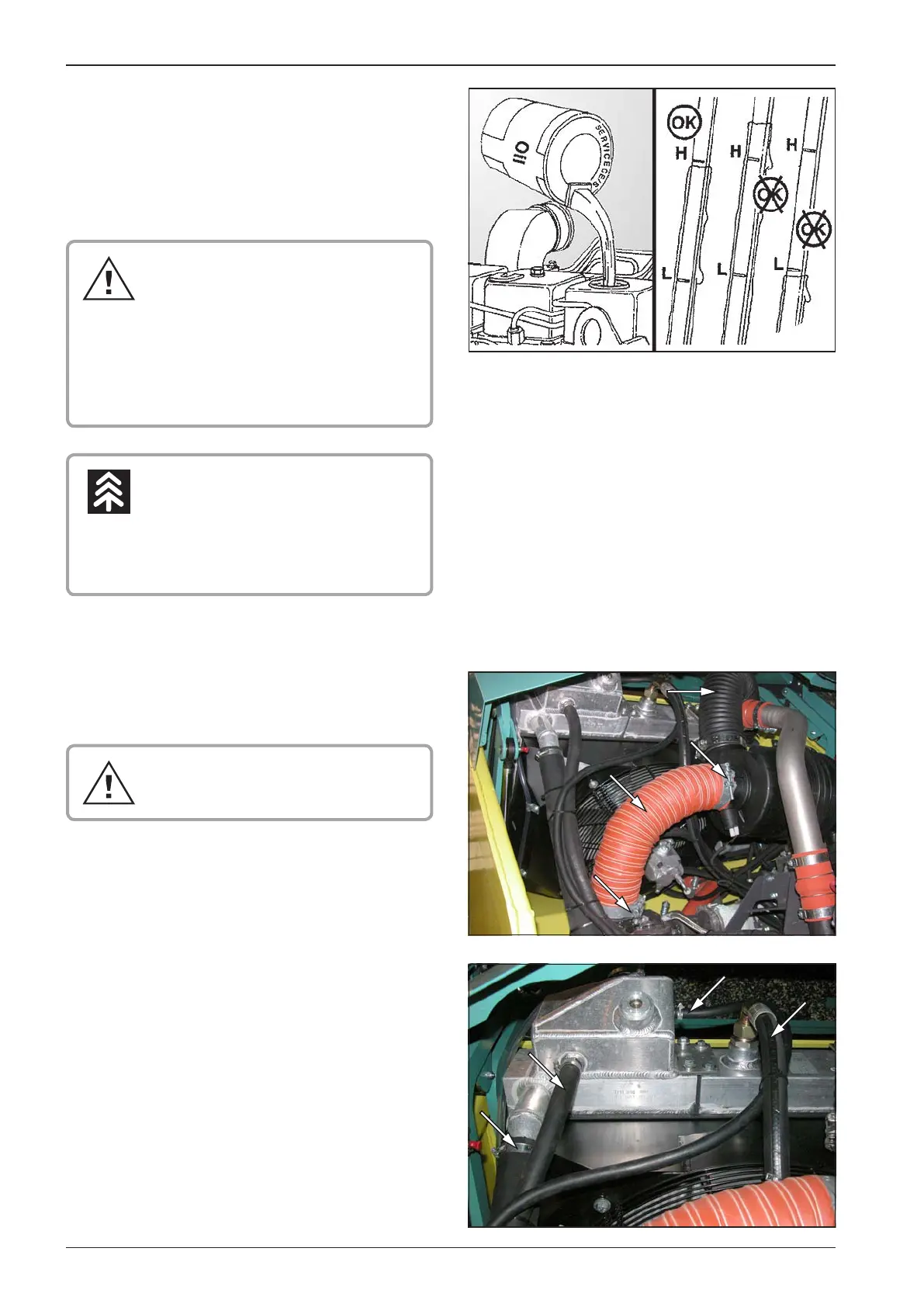

Note

Fill up to the dipstick’s top division mark. Total sump capac-•

ity is 7 l (1,85 gal US).

When oil is exchanged, start the engine and let it run at •

higher idle rmp for 2 - 3 min.

Stop the engine and wait for ca 3 min until oil descends into •

the crankcase, then check the proper oil level.

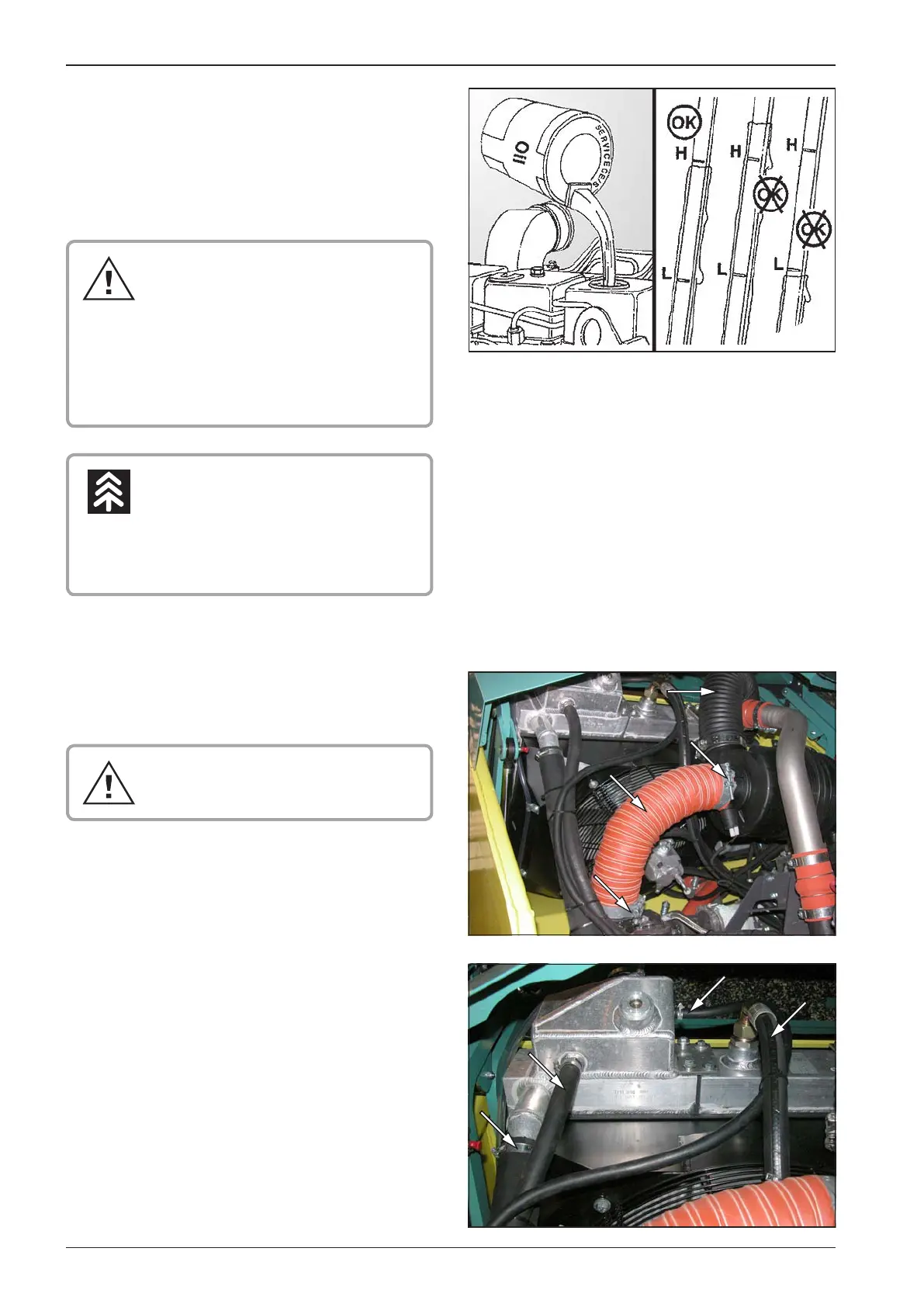

3.6.13. Inspect engine cooling circuit

Check the cooling circuit tightness. Conrm no pipes are •

damaged and no clamps are missing.

3.6.12. Inspect engine induction manifold

Check the pipes and clamps.•

Do not operate the Machine if pipes and

clamps are damaged!

Loading...

Loading...