L0118G

4-4

6. Enter the price and press * to save this price,

then do one of the three things listed below:

a. To save the selection at this price

press * again.

b. Press 1 to save all the tray

selections at this price.

c. Press 2 to save all the vendor

selections at this price.

7. The prices as set will be maintained by the

vendor even if there is a power failure or if

the machine is unplugged: however, prices

will need to be reset if the configuration of

motors or trays is changed.

8. Using the * or # keys, scroll through the

menu, or exit the service mode by pressing

the mode switch or closing the vendor door.

4.3 ON-SITE INSTALLATION

Remove the Shipping Boards

1. Split the shipping boards by inserting a

crowbar or wedge into the slots at either end.

2. If necessary, lift the vendor to remove the

broken boards using properly rated

equipment. Do not tilt the vendor. Do not

attempt to lift the vendor with a 2-wheel hand

truck.

Placing the Vendor in Location

1. Place the vendor within 5 feet of the

designated power outlet. The power outlet

should be accessible when the vendor is in

position, and the ventilation opening in the

back of the vendor must be clear of

obstructions.

2. For refrigerated models, allow at least 4

inches between the wall and the back of the

vendor for air circulation.

3. Make sure the vendor does not block

walkways or exits.

4. Do not place the vendor in a location where

it can be struck by vehicles.

5. Leave at least 18 inches between a wall and

the hinge side of the vendor to prevent the

door hitting the wall when opened, or use a

protective wall bumper. The door must open

wide enough to allow the trays to be pulled

out.

6. The vendor is designed to meet the 1991

ADA guidelines for persons in wheelchairs

using a parallel approach (side of wheelchair

adjacent to front of vendor). Make sure there

is adequate room to maneuver a wheelchair

into this position in front of the vendor.

Leveling the Vendor

For safe operation and for proper coin handling by the

coin changer, the vendor must be level.

1. On the bottom of the vendor are four (4)

threaded leveling legs located at the corners

of the cabinet and a fifth support screw

under the door. Before beginning, be sure

that all five leveling legs are screwed in

completely.

2. With the door closed and locked, check the

four main legs and adjust any leg that is not

contacting the floor. Make sure the support

screw under the door is all the way up and is

not contacting the floor at this time.

3. Place a level on top of the cabinet and check

for horizontal from side-to-side.

4. Adjust the leveling legs on the low side one

turn at a time until the cabinet is level.

5. Repeat the last two steps to level the vendor

front-to-back.

6. After the vendor is level, adjust the support

screw under the door until it contacts the

floor.

False Leg Installation

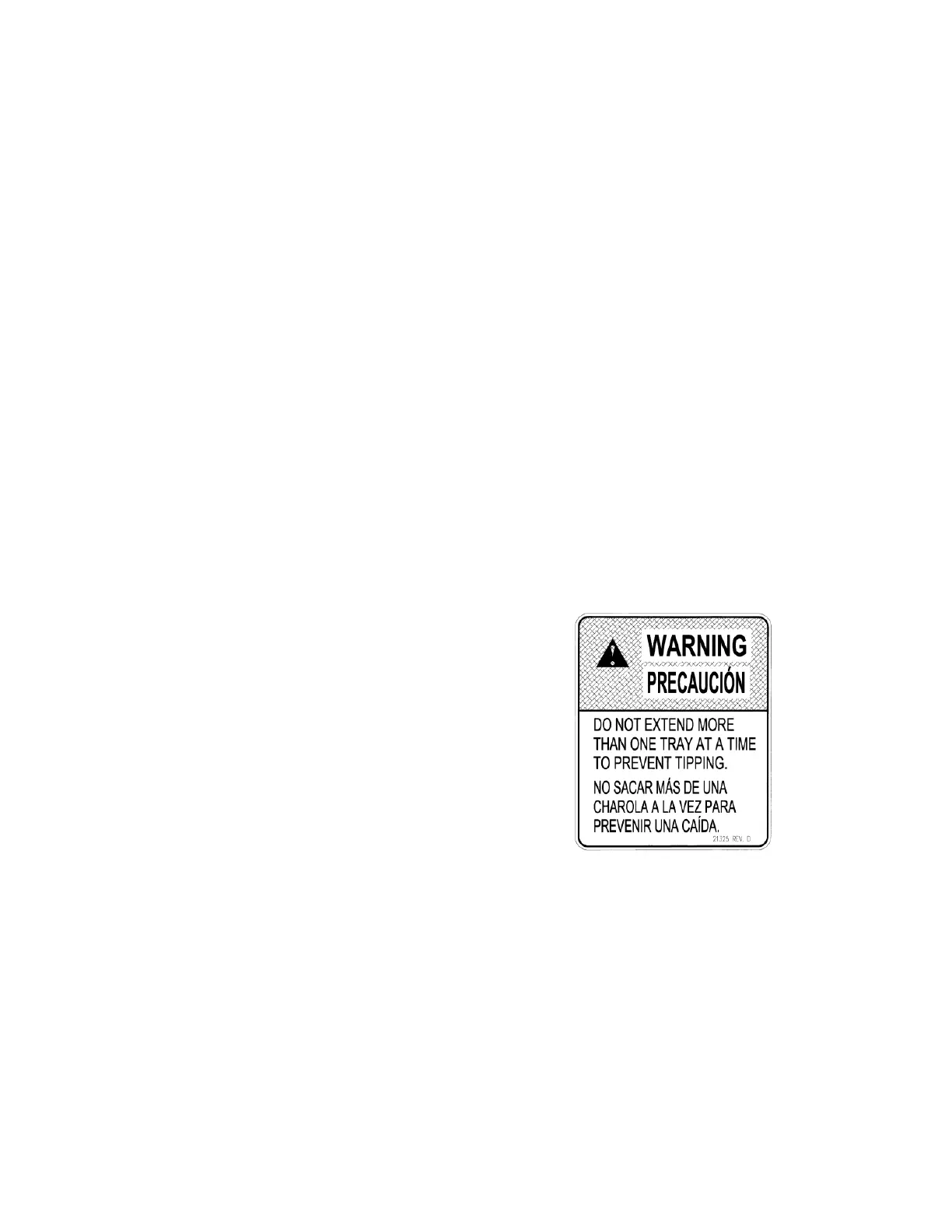

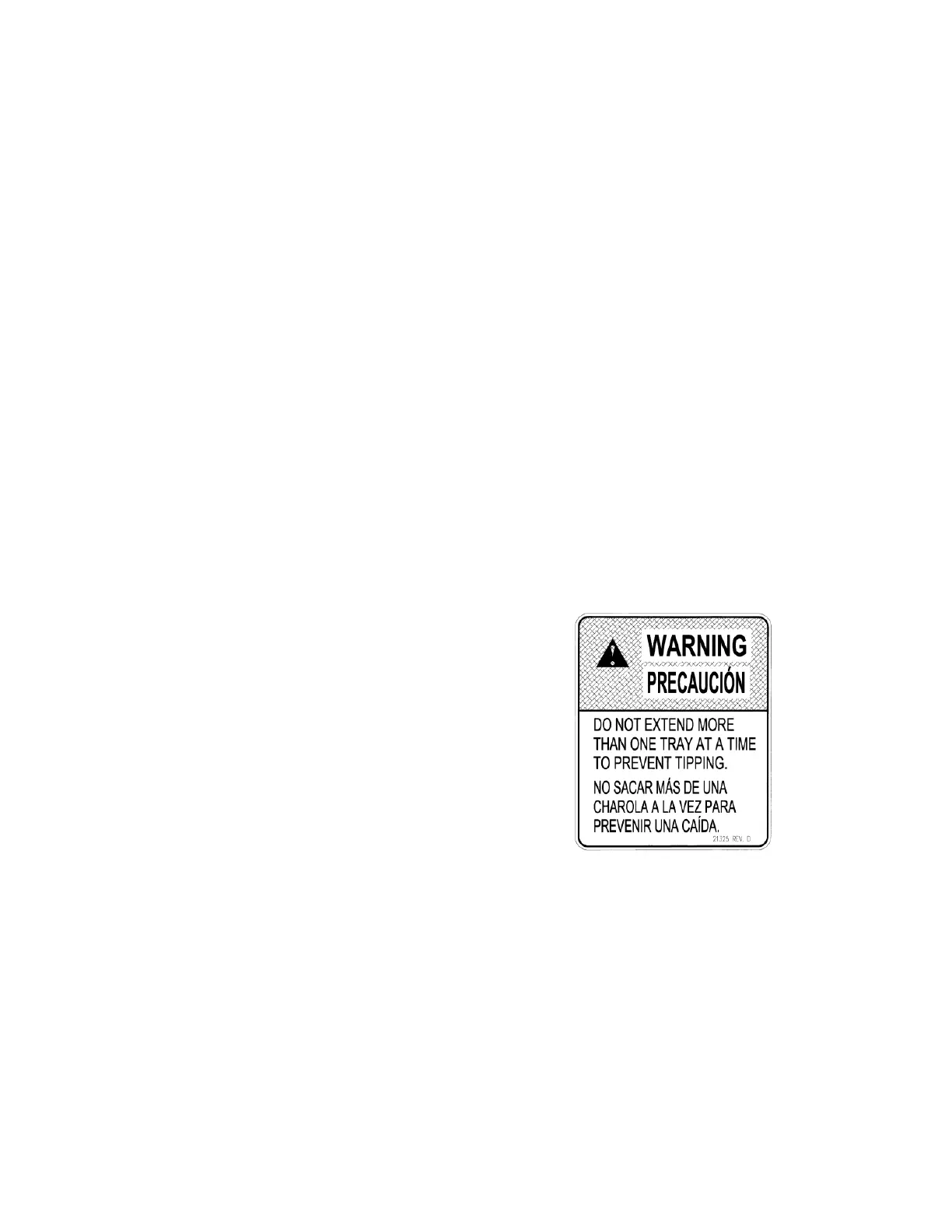

WARNING

The False Leg helps to prevent the machine from

tipping forward when the vendor door is open and

one or more bottle trays are extended. Failure to

install the false leg on vendors with bottle trays

may result in serious injury (Refer to Figure 4.2).

Figure 4.1 Tip-Over Warning

CAUTION: Wear gloves-edges may be

sharp! Always wear eye

protection when servicing

vendor!

TOOLS REQUIRED:

1/4” Nut driver or socket wrench

1. Align the holes in the top of the false leg with

the 1/8” holes on the left side of the bottom

of the door (Refer to Figure 4.2). The closed

end of the false leg should be facing forward.

2. Install screws through the holes and tighten

until snug. Do not over tighten.

Loading...

Loading...