L0118G

8-5

Replacing Optional LED Lamps

1. Open the door.

2. Turn off the power to the control board by using

the power switch.

3. Locate the LED harness and remove it from the

MDB harness.

4. Remove the screws holding the large and small

P-clips, and remove the LED lamps.

5. Install the replacement LED lamps, using the

small and large P-clips and the screws.

6. Connect the LED harness to the MDB harness.

7. Turn on the power to the control board.

8. With the LED lamps operating, turn the LED

lamps to direct the light into the vendor.

9. Close the vendor door.

8.10 DEFROSTING THE EVAPORATOR COIL

Excess moisture accumulating inside the cabinet may

freeze in the evaporator coil. As the coil becomes

blocked all useful chilled air is also blocked.

1. Unplug the vendor

2. Open the door.

3. If the vendor has entered an H&S vending hold,

the food products should be disposed of.

4. Place a fan on the floor in front of the vendor to

direct room temperature air into the back of the

cabinet.

5. Do not use any tools or electrical appliances to

chip at, heat up or otherwise “speed up” the

defrosting action around the coil. Do not

puncture the coil.

6. Check to see if the base under the evaporator

drain pan is the non-freezing type, which has

two large rectangular vent holes formed in its

longest side. If the base is made without these

large holes contact AMS to arrange for a Non-

Freezing Evaporator Drain Pan Kit (Refer to Kit

Drawing 21351).

7. Look for the source of excess moisture.

8. Look for broken or leaking product. Dispose of it

and clean up the liquid.

9. Inspect the vend hopper and clean it of liquids

and broken containers.

10. Check to make sure the vend hopper door

doesn’t hang open.

11. Check that the gasket of the chiller housing is

securely contacting the cabinet and is sealing it

on all sides.

12. Check to ensure the sealing putty is firmly in

place around the two openings on the rear, right

hand edge of the chiller housing. Use more

putty if it is missing or is not enough.

13. Check the door gasket around the cabinet

opening. It should be intact.

14. Check to see if the door closes squarely on all

four sides and the lock draws the door firmly

against the gasket.

15. After the evaporator coil has been defrosted,

clean up any water inside the cabinet.

16. Close the door.

17. Plug in the vendor and allow vendor to cool

down before loading perishable products.

8.11 TESTING THE TEMPERATURE SYSTEM

(Health and Safety)

Note: This feature is only available when the P/N

3427 Software is installed.

1. Enter the service mode (Refer to Section 6.0).

2. Press “#” or “

*” until the Temperature section

appears, then press 2 to view the current set

point. The temperature will be displayed in both

Fahrenheit and Celsius. The setpoint of the

vendor must be 41°F or lower for the H&S

option to be enabled.

3. Press 5 to initiate the NAMA H&S 15 minute

Automatic Shutoff Controls test. At this point the

sensor can either be temporarily disconnected,

causing the controller to assume a temperature

of 125°F/49C, or relocated outside the cabinet.

Relocating the sensor outside will allow the

sensor to be tested as well.

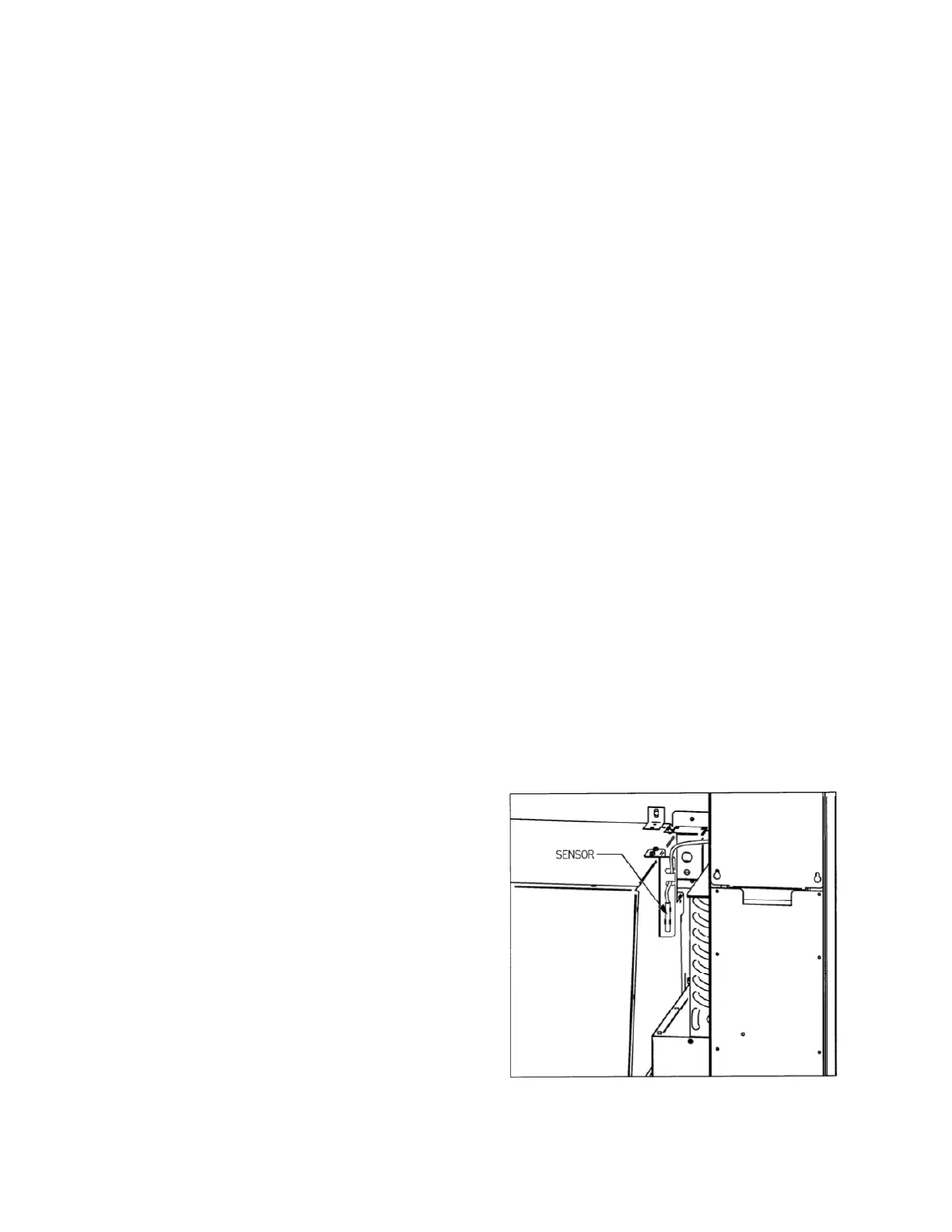

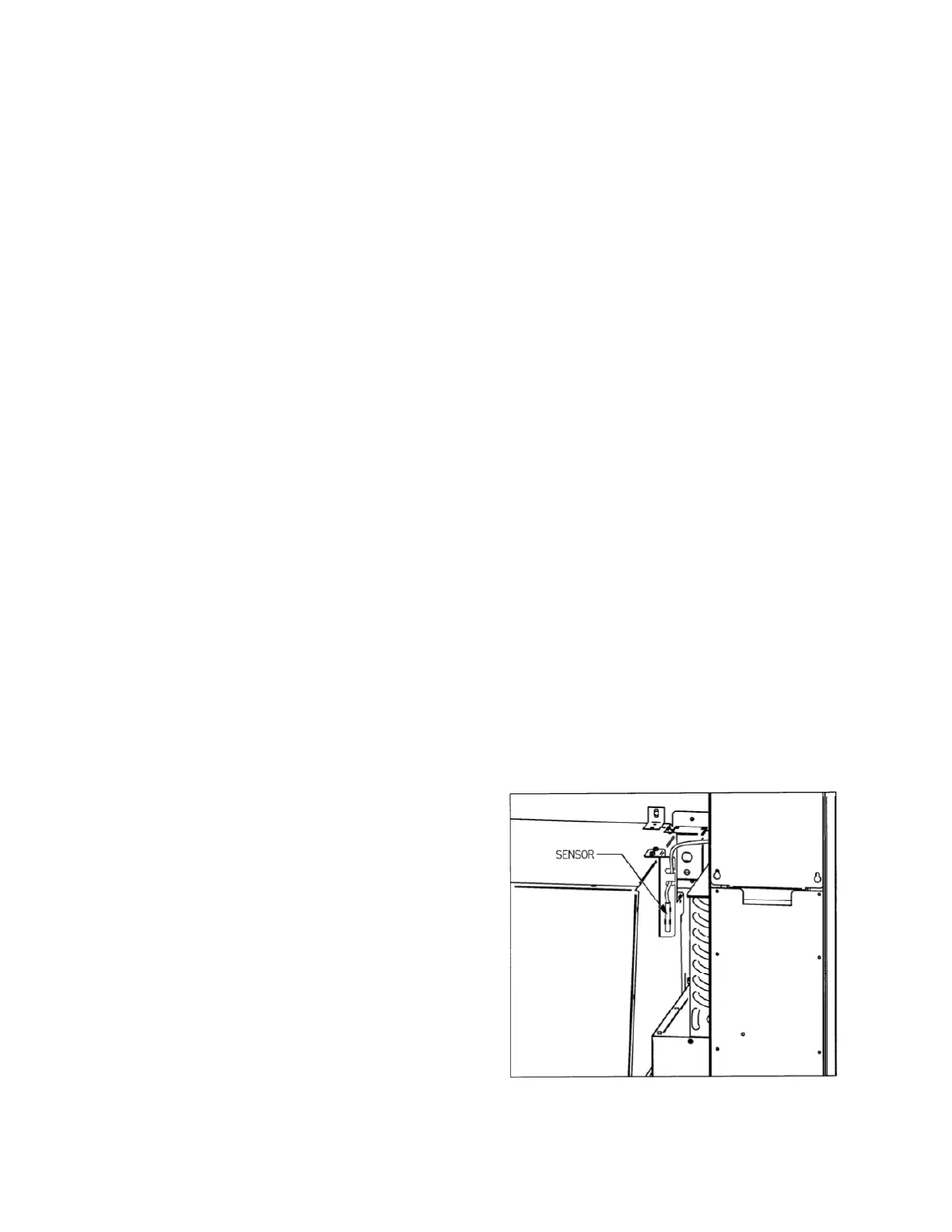

4. The sensor is mounted to its bracket using two

spring clamps (Refer to Figure 8.4). To remove

it, first unwrap the sensor wire from the two slots

in the bracket, and then slide the sensor out of

the two spring clamps.

5. Relocate the sensor outside the vendor, and

allow to warm up (above 41°). Carefully close

the door. The temperature may be monitored by

pressing the * button. The sensor bulb has a

20-25 second response delay to minimize

hysteresis error before the correct temperature

is displayed.

15 minutes after the door is closed, the display should

read “OUT OF SERVICE- HS1”. The vendor will not

vend protected products until the door is opened and

the error is cleared (Refer to Section 6.2).

Figure 8.4 Temperature Sensor

Loading...

Loading...