L0118G

5-3

5.7 HELIX ADAPTER

1. To remove, twist the adapter to free the mounting

leg from the locking tab.

2. Reverse the removal procedure to reinstall.

5.8 HELIX EJECTOR

The ejector’s function is to cause the product to fall

sooner, and therefore stop the helix sooner. This will

help retain the next product in the helix coil, especially

if they are difficult products.

1. The helix ejector is pulled off and pressed on the

helix by hand.

2. The ejector is typically positioned half a coil, and

often much less, from the end of the helix.

3. The “fin” shaped portion is angled towards the

front of the tray.

The best position and angle for the ejector is

determined by test vending products.

5.9 HELIX ALIGNMENT DEVICE

The helix alignment device is installed under the

bottom left side of the large helices to help keep them

centered in their columns.

1. To remove, grasp the front of the helix alignment

device with pliers and pull or pry upward. Take

care not to lose the plastic mounting clips.

2. Reinstall by pressing the plastic mounting clips

back into the mounting holes. Note that the

mounting flange goes toward the helix.

5.10 MOTOR POSITIONS / HOME

Motor position can be changed sideways for different

width columns, and there are two mounting positions

on the snack tray. The lower and upper positions are

used for the small and large helices, respectively.

1. Remove the helix. Remove the harness terminals

(one small and one large).

2. Press down and rearward on the top mounting

tab, then pull the lower mounting legs out of the

mounting slots.

3. Reverse the removal procedure to reinstall.

4. After all motor changes have been made use the

Tray Setup option in Service Mode to

configure

the motors

.

5. The vendor will not vend from a given helix when

the motor is missing, jammed or has home switch

problems.

6. After a motor has been configured check to make

sure all the helices are in the home position. If

the end of a helix is not at its lowest position in

the column pull it out of the motor, turn it until it

is, and reinsert the helix into its motor.

5.11 BOTTLE TIPPER BAR

The bottle tipper bar is typically used with carbonated

beverage bottles. The bottles stand upright. The

tipper bar restrains the top of the bottle so that it falls

bottom first, rather than tumbling off the tray.

1. To remove, bow the bar until one end can be

pulled free from the support bracket. Take care

not to lose the plastic bushings in the supports.

2. To reinstall, reverse the removal procedure.

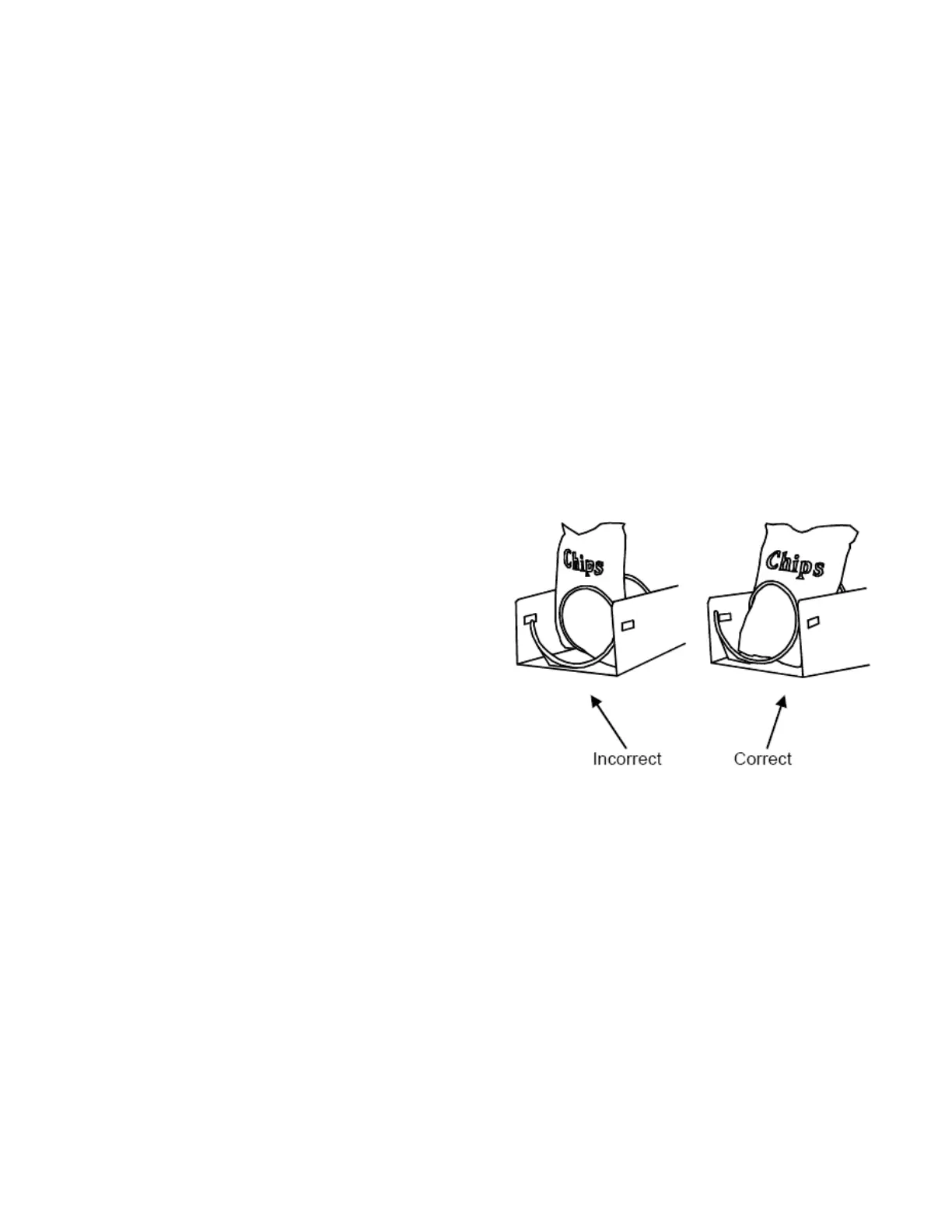

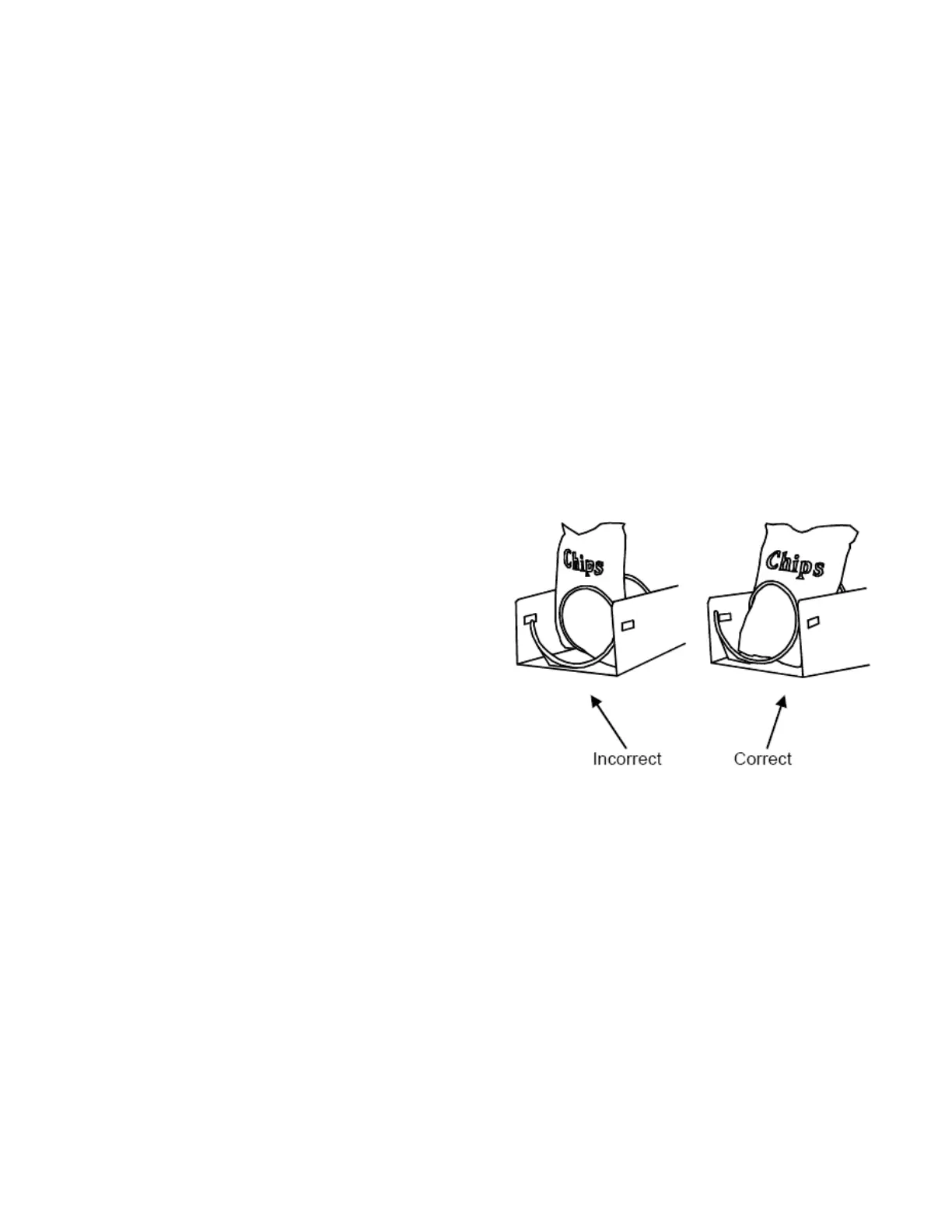

5.12 AVOIDING PRODUCT HANG-UPS

Avoid large products, such as chips, from “hanging-

up” between the tray and the glass by loading them

“left corner first” into the helix. The bottom left corner

of the bag should be in front of the helix to let the helix

push the bottom out first (Refer to Figure 5.2). An

incorrect loading may cause the bag to fall top first,

which could lead to a hang-up. Loading “left corner

first” prevents the product from falling top first.

Figure 5.2 Large Bag Vending

5.13 TALL PRODUCT VENDING

Place tall, narrow products in a column with a candy

pusher bar. Typically these are installed in columns 8

and 9 on the candy trays. Rotate the bar upward or

downward to the desired position. It should hold the

product upright, but not pinch or bind the product.

5.14 CANDY PUSHER BAR INSTALLATION

The candy pusher bar is an adjustable bar that

mounts to any tray divider to keep tall candies from

falling sideways (Refer to Figure 5.3). Four pusher

Loading...

Loading...