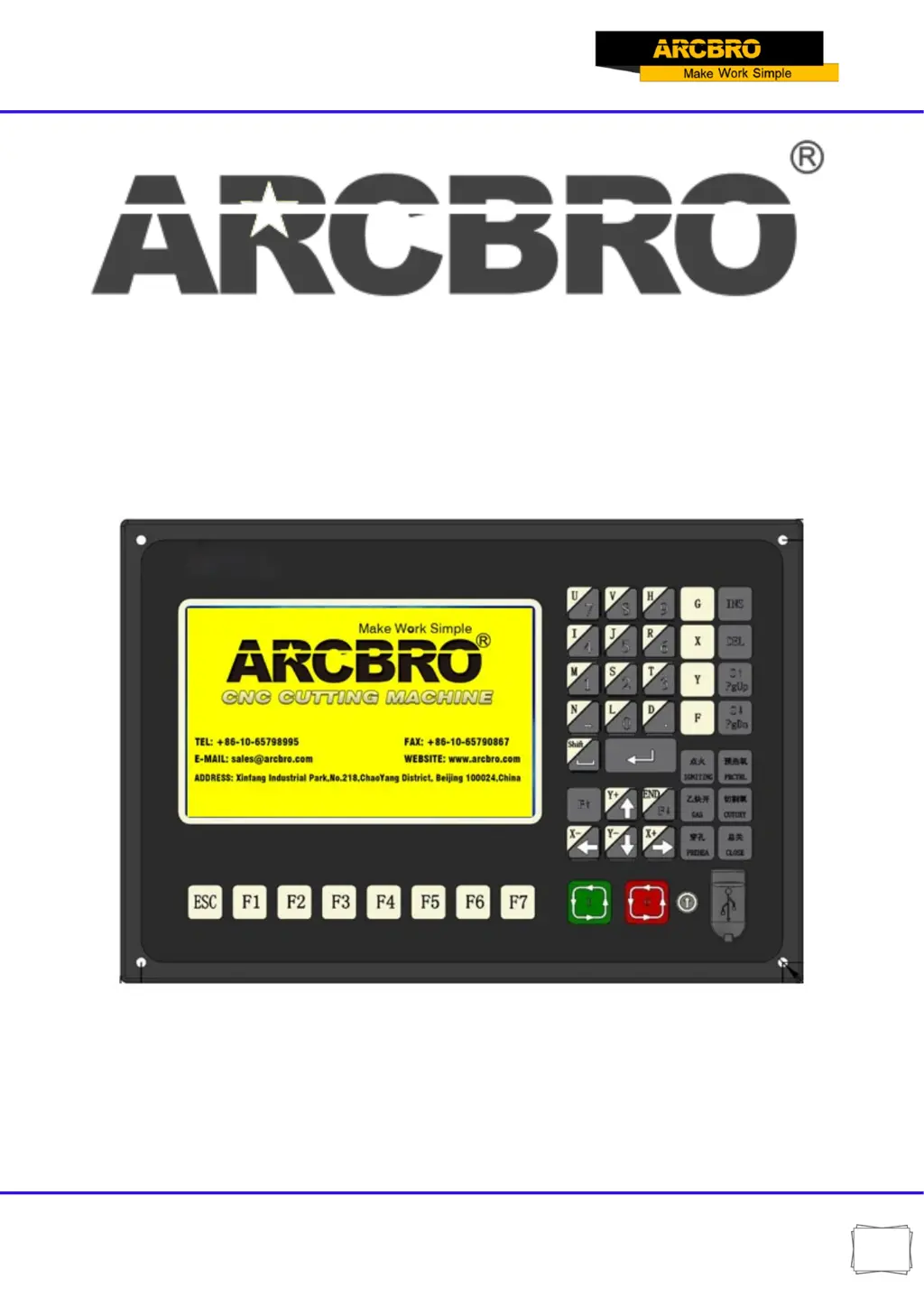

What to do if ARCBRO Cutter torch doesn't move along one axis?

- Bbrandon46Aug 2, 2025

If the ARCBRO Cutter torch doesn't move along one axis and ignores keystrokes, the machine operation might be interrupted. First, remove any interference and ensure the plasma power supply's grounding wire is connected to the machine. Next, check if the motor (previous model) has an isolation board. Finally, if it's in flame mode, verify if the solenoid valve for cutting oxygen is causing arc extinction.