installation &

operating instructions

Design Envelope 4300 and 4380 vertical in-line

pumping unit with integrated controls

12

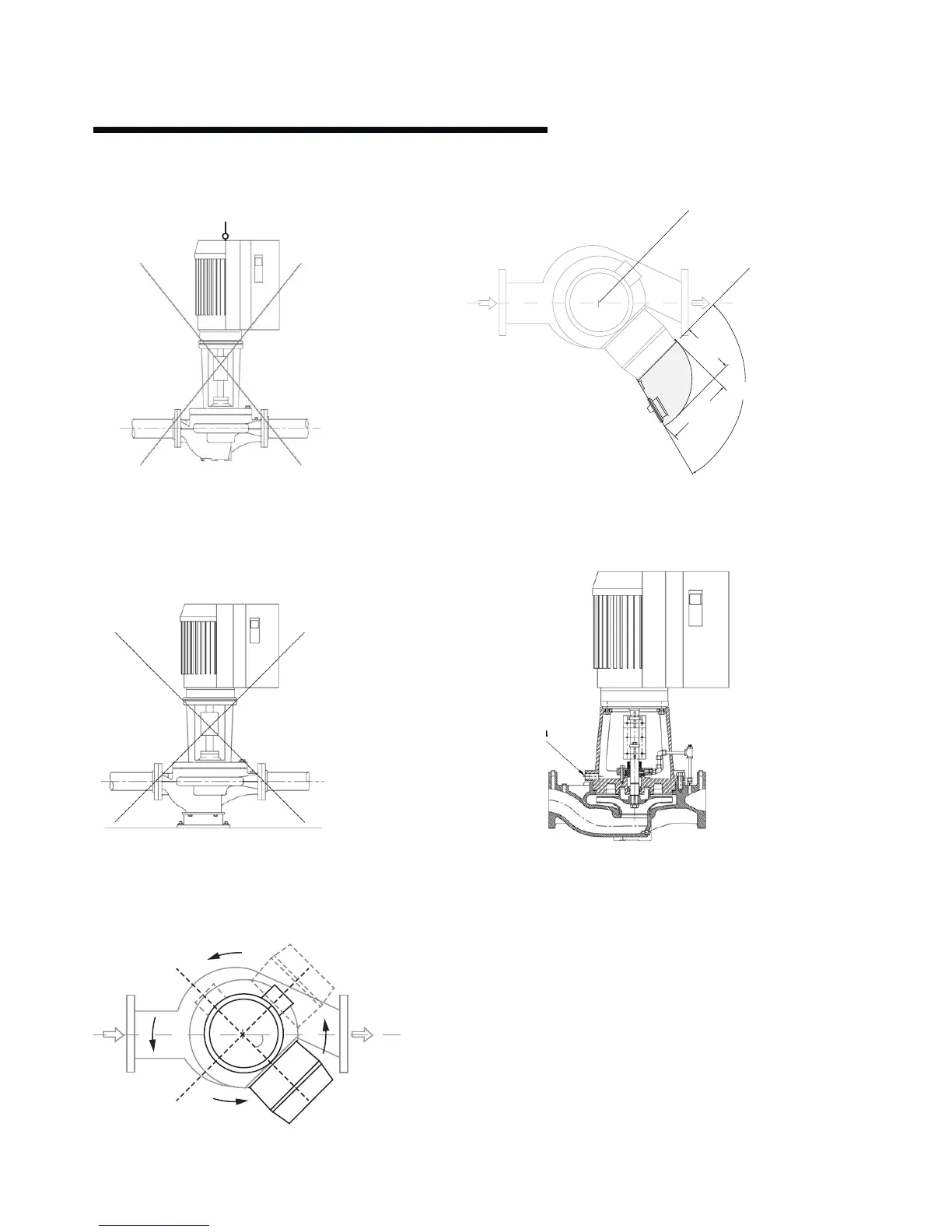

fig. 2.10 Motor lifting hook supported

Page 8 of 26

15.70”

(399)

≤105°

20.70”

(526)

45°

29.50” (749)

Typical

Fig. 2.10 Motor lifting hook supported

Fig. 2.11 Mounted on rigid base without exible connectors

Fig. 2.14 Tapped collection well on Series 4300

Fig. 2.9 Mounting in grooved pipe systems

Fig. 2.13 Clearance radius for D size chassis

Fig. 2.12 Motor and integrated controls assembly can be

rotated in 90° increments to meet installation spacing

requirements.

fig. 2.11 Mounted on rigid base without

flexible connectors

Page 8 of 26

15.70”

(399)

≤105°

20.70”

(526)

45°

29.50” (749)

Typical

Fig. 2.10 Motor lifting hook supported

Fig. 2.11 Mounted on rigid base without exible connectors

Fig. 2.14 Tapped collection well on Series 4300

Fig. 2.9 Mounting in grooved pipe systems

Fig. 2.13 Clearance radius for D size chassis

Fig. 2.12 Motor and integrated controls assembly can be

rotated in 90° increments to meet installation spacing

requirements.

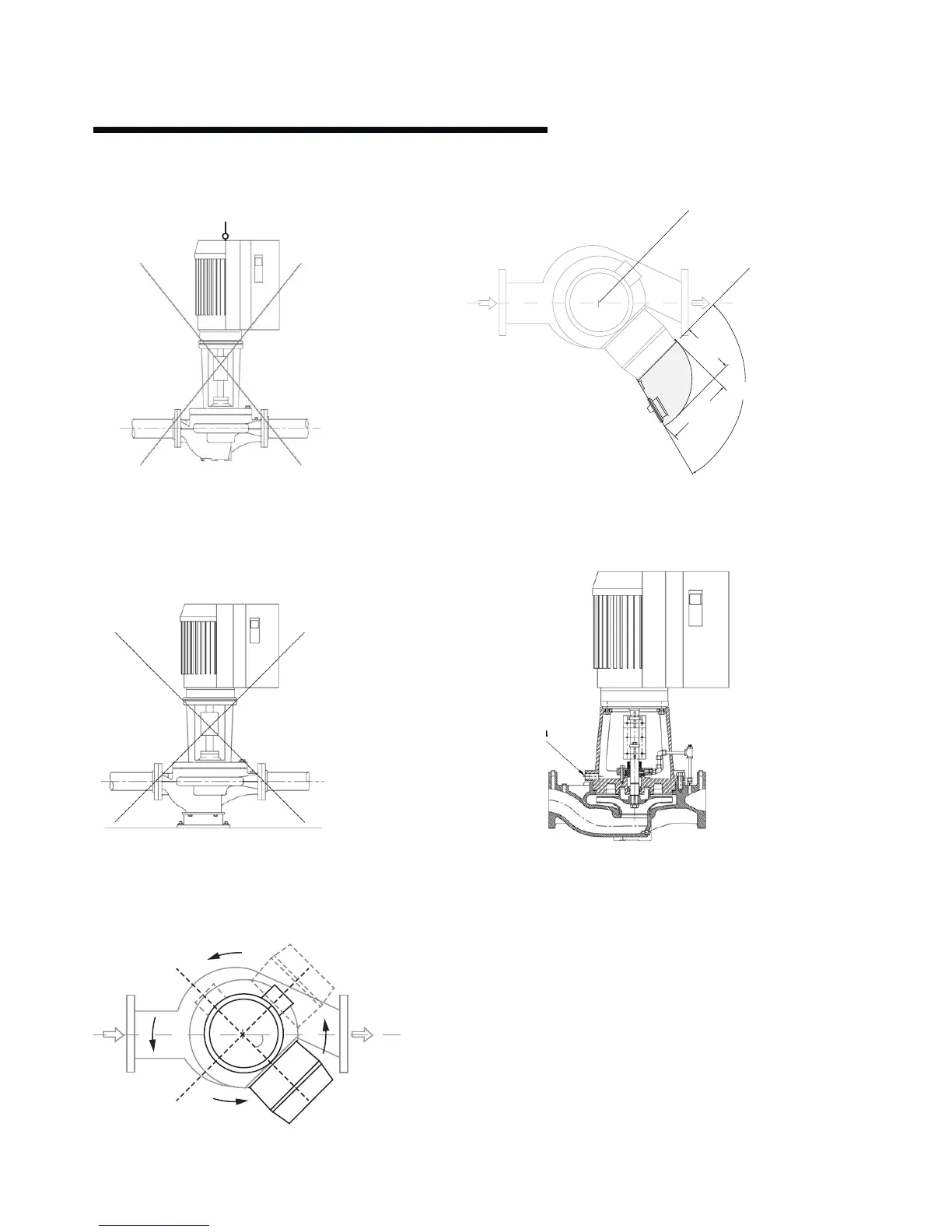

fig. 2.12 Motor and integrated controls assembly can be

rotated in

90°

increments to meet installation spacing

requirements

Page 8 of 26

15.70”

(399)

≤105°

20.70”

(526)

45°

29.50” (749)

Typical

Fig. 2.10 Motor lifting hook supported

Fig. 2.11 Mounted on rigid base without exible connectors

Fig. 2.14 Tapped collection well on Series 4300

Fig. 2.9 Mounting in grooved pipe systems

Fig. 2.13 Clearance radius for D size chassis

Fig. 2.12 Motor and integrated controls assembly can be

rotated in 90° increments to meet installation spacing

requirements.

fig. 2.13 Clearance radius for d size chassis

15.7

(399)

20.7

(526)

≤105,0°

29.5"typ

15.7

(399)

fig. 2.14

Tapped collection well on series

4300

Page 8 of 26

15.70”

(399)

≤105°

20.70”

(526)

45°

29.50” (749)

Typical

Fig. 2.10 Motor lifting hook supported

Fig. 2.11 Mounted on rigid base without exible connectors

Fig. 2.14 Tapped collection well on Series 4300

Fig. 2.9 Mounting in grooved pipe systems

Fig. 2.13 Clearance radius for D size chassis

Fig. 2.12 Motor and integrated controls assembly can be

rotated in 90° increments to meet installation spacing

requirements.

Series 4300 seal leaks or

condensate drain hole. Plumb to

drain for area cleanliness.

Loading...

Loading...