44

12.4.2 changing data

The procedure for changing data depends on whether the

selected parameter represents a numerical data value or a

text value.

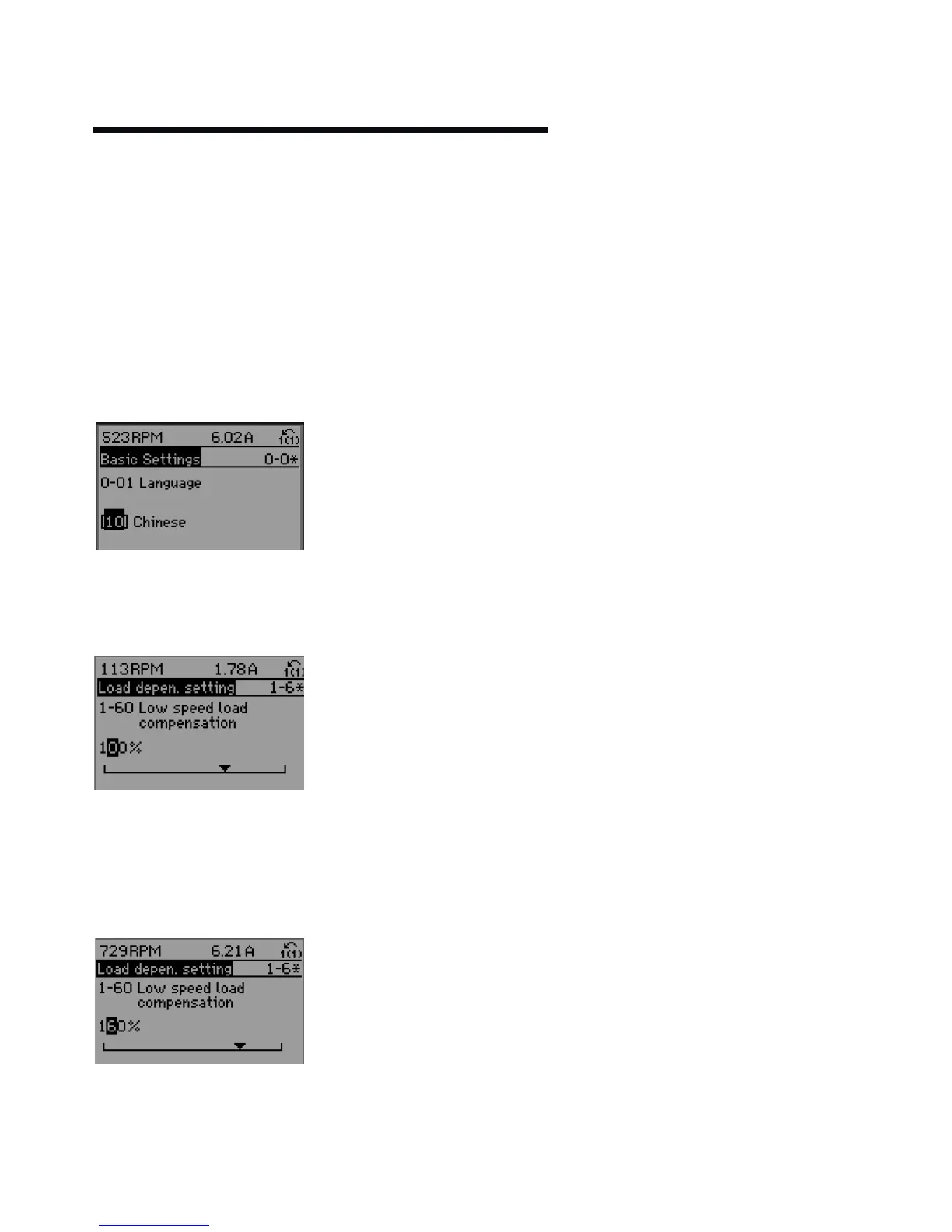

Changing a text value

If the selected parameter is a text value, change the text

value by means of the [p] [q] navigation keys.

The up key increases the value, and the down key decreases

the value.

Place the cursor on the value you want to save and press OK.

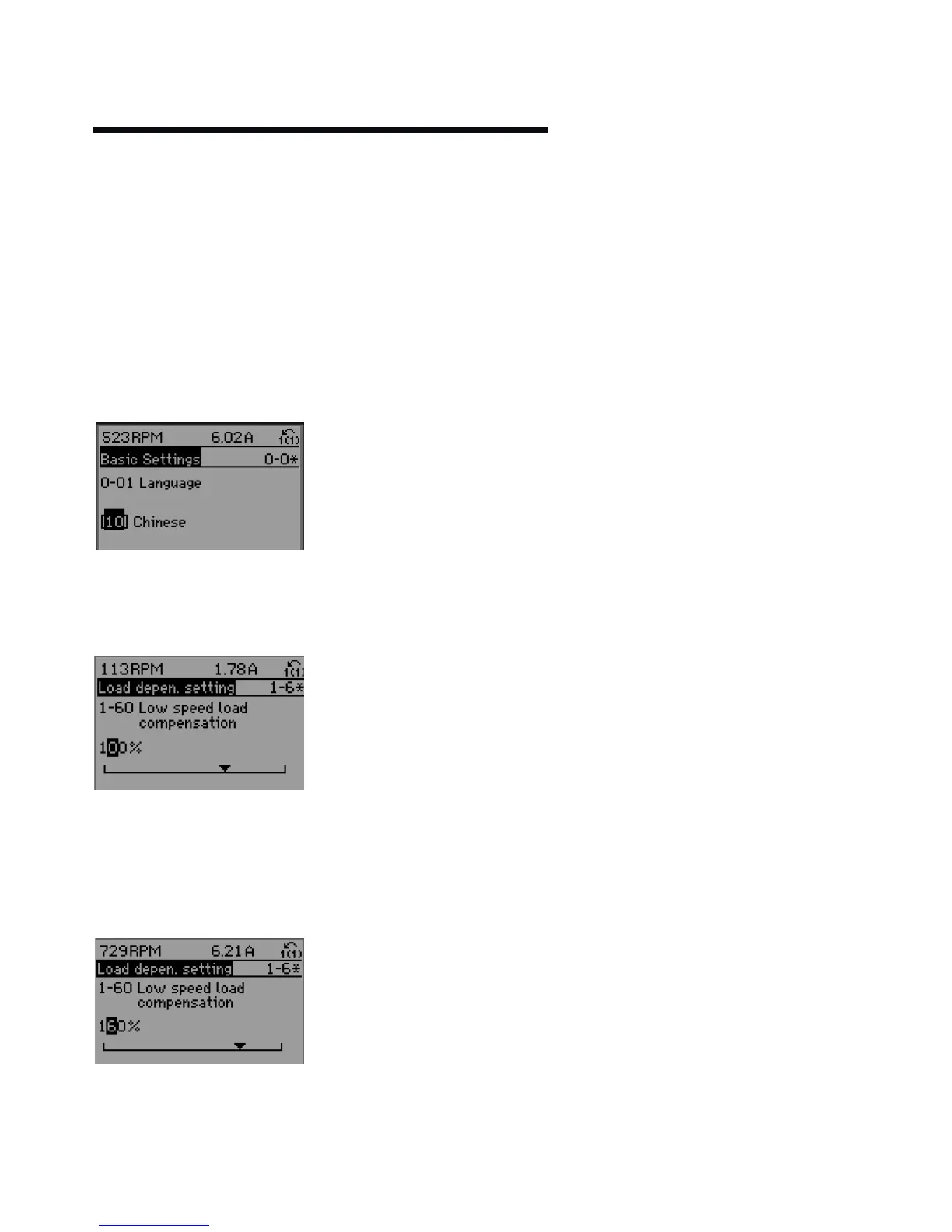

Changing Numeric Data Values

If the chosen parameter represents a numeric data value,

change the chosen data value by means of the [] [] navi-

gation keys as well as the [p] [q] navigation keys. .

Use the [] [] navigation keys to move the

cursor horizontally.

Use the [p] [q]navigation keys to change the data value.

The up key enlarges the data value, and the down key re-

duces the data value. Place the cursor on the value you want

to save and press OK.

Readout and Programming of Indexed Parameters

Parameters are indexed when placed in a rolling stack.

Par.15-30 Alarm Log: Error code to Par.15-33 Alarm Log: Date

and time contain a fault log which can be read out. Choose a

parameter, press OK, and use the up/down navigation keys

to scroll through the value log.

Use

Par.

3-10 Preset Reference as another example:

Choose the parameter, press OK, and use the up/down navi-

gation keys to scroll through the indexed values. To change

the parameter value, select the indexed value and press OK.

Change the value by using the up/down keys. Press OK to

accept the new setting. Press Cancel to abort.

Press Back to leave the parameter.

13.0 sensorless operation

Sensorless control is an innovative concept in circulating

pumps. Pump performance and characteristic curves are

embedded in the memory of the speed controller during

manufacture. This data includes power, speed, head and flow

across the flow range of the pump. During operation, the

power and speed of the pump are monitored, enabling the

controller to establish the hydraulic performance and posi-

tion in the pumps head-flow characteristic.

These measurements enable the pump to continuously iden-

tify the head and flow at any point in time, giving accurate

pressure control without the need for external feedback

signals. Patented software technology within the controller

ensures trouble-free operation in all conditions.

Incorporating the pumps hydraulic data into the controller

and removing sensors results in true integration of all com-

ponents and removes the risk of sensor failure.

13.1 default operating mode —

quadratic pressure control

The default control mode for Design Envelope pumps is

‘Quadratic Pressure Control’ where the controller is set to

control the speed according to a ‘control curve’ between max

and min flow (see below diagram). It is widely recognised

that fitting a dierential pressure sensor at the most remote

load, across the supply piping and return piping encompass-

ing the valve & coil set, is the benchmark scheme for

energy eciency.

Loading...

Loading...