13

3.0 ce conformities

For Declaration of Conformity certificates please

contact Armstrong.

The Design Envelope product conforms to the requirements

in the following directive(s), standard(s) or other normative

document(s):

low voltage directive 2006/95/ec

emc directive 2004/108/ec

machinery directive 2006/42/ec

ecodesign directive 2009/125/ec

4.0 mechanical installation

Install the Design Envelope unit with adequate access for routine

maintenance. Adequate space, particularly at the fan inlet (50

mm), is necessary to facilitate airflow. Where several Design En-

velope units are installed in close proximity, care must be taken

to ensure that there is no re-circulation of exhausted warm air.

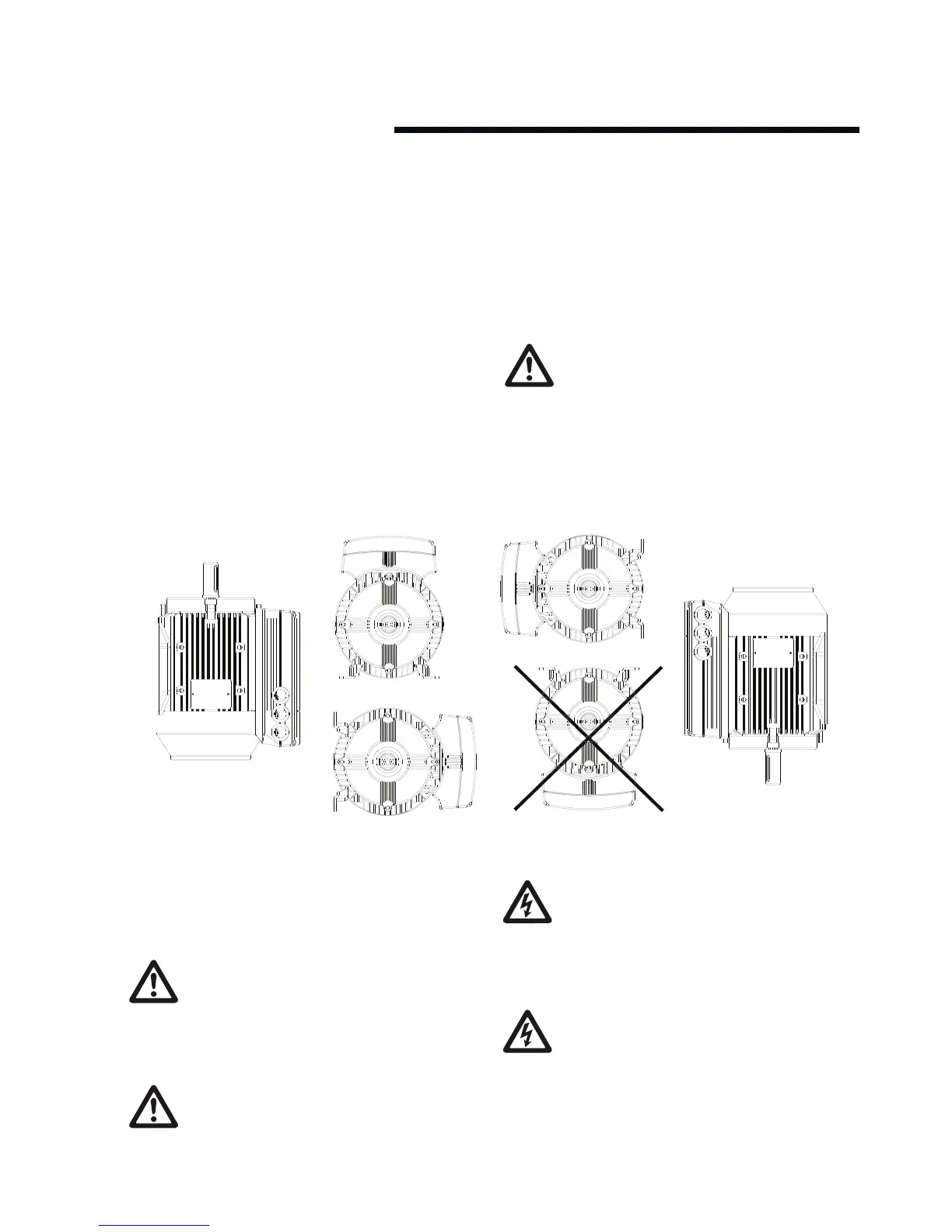

With reference to fig. 3, the pump should not be

installed with the inverter in the underside position.

This guidance pertains to all pump types and

overrides any instruction in the particular pump

Installation, Operation and Maintenance Instruction.

integrated controls

Power Rating 0.55 kW - 7.5 kW

4.1 enclosure rating

The standard enclosure rating for Design Envelope

pumps is ip55. If the pump is to be installed in a wet or

dusty environment then a higher enclosure rating may

be required (ip56 or ip66 option).

4.2 ambient temperature

To avoid the inverter unit getting overheated, the

ambient temperature is not to exceed 40°c and the 24

hour average temperature is not to exceed 35°c. If the

ambient temperature is in the range of 40°c - 55°c, a

reduction of the service life of the inverter part is to be expected.

5.0 electrical installation

All electrical connections should be carried out by a

qualified and authorised electrician in accordance with

local site regulations and the latest issue of the

iee regulations.

safety, risk of death

Before removing the inverter cover, the system must

be disconnected from the mains supply. After switch-

ing o wait for at least five minutes for the capacitors

to discharge before opening the cover.

fig. 3 Allowable Installation Orientation - On-board Inverter Position

Loading...

Loading...