17

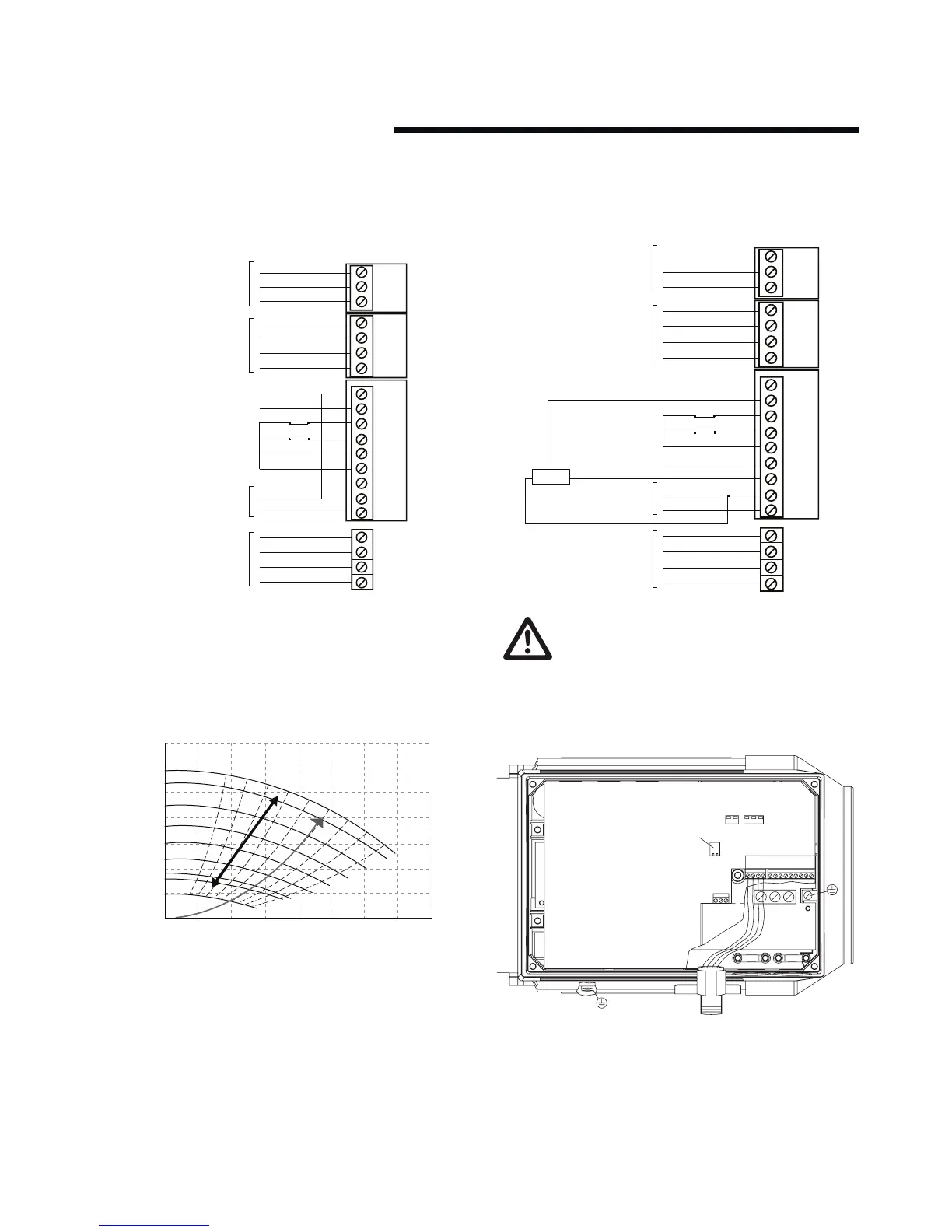

iii Constant curve mode - bms speed control

Where the Building Management System is to be used for

speed control it is necessary to disable sensorless control

and provide the unit with a 0 - 10v dc speed reference signal.

As shown above, in Constant curve mode the pump will speed

up and slow down according to the voltage level of the reference

signal. On a unit configured for 50 hz pump speed the reference

signal is scaled (by default) so that 0v on x100 terminal 2 will

equate to 0 hz and 10v will equate to 50 hz.

iv Constant curve mode - Potentiometer speed control

If a potentiometer is to be installed for manual control of

pump speed then the control connections will be as follows:

The recommended minimum speed for Design

Envelope pumps is 580 rpm. Running for long periods

below this speed can damage the mechanical seal.

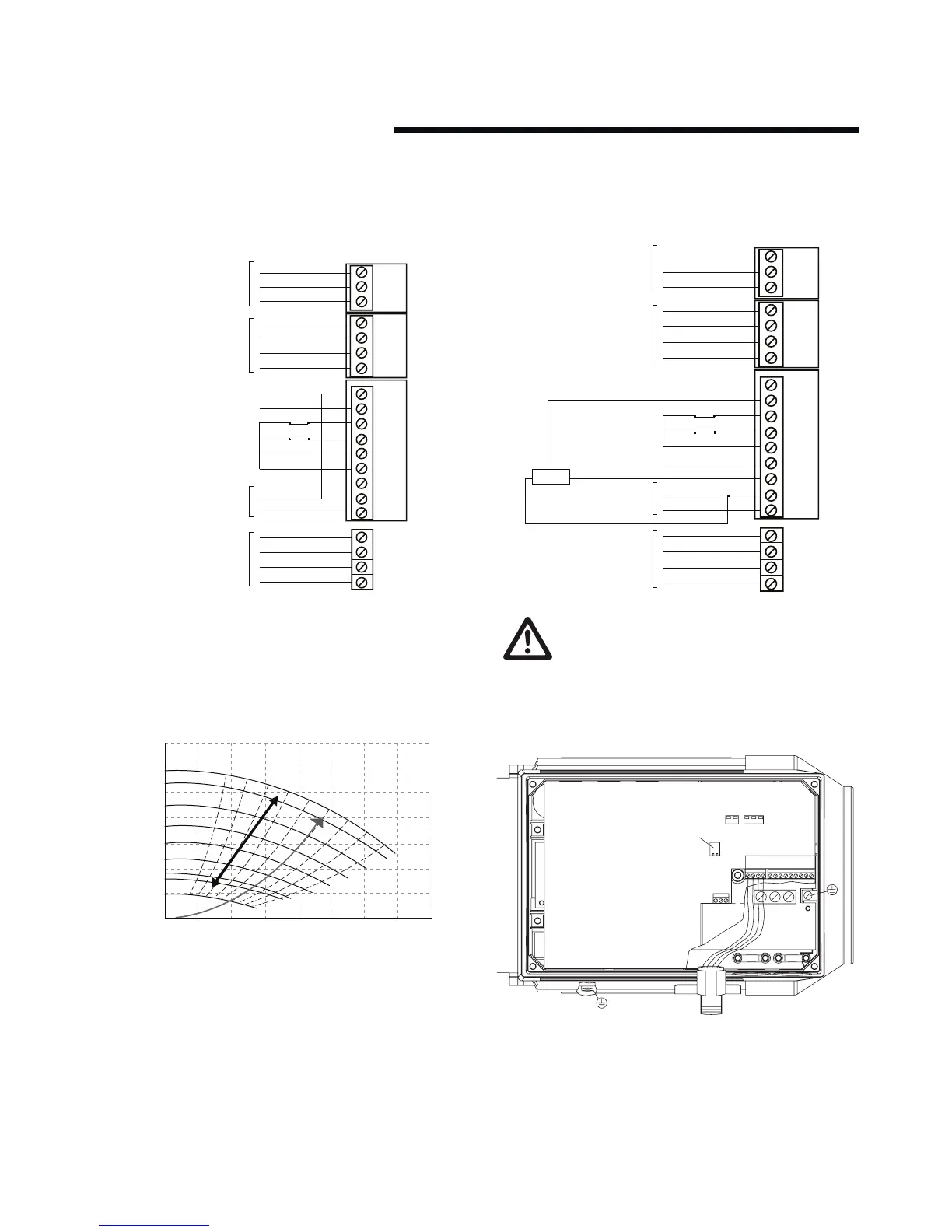

6.0 programming, monitoring

and diagnostics

A key pad tool (lcp) is available for Design Envelope Pumps as

an option. The lcp gives the user full programming and monitor-

ing capabilities and it is recommended that at least one lcp and

cable kit are purchased for each installation site.

The lcp is connected via a cable to the ‘plug kit’ mounted in one

of the inverter cable entries as shown above.

1

2

3

x102

1

2

3

4

x100

1

2

3

4

L1

L2

L3

PE

5

6

7

8

9

x101

Loading...

Loading...