39

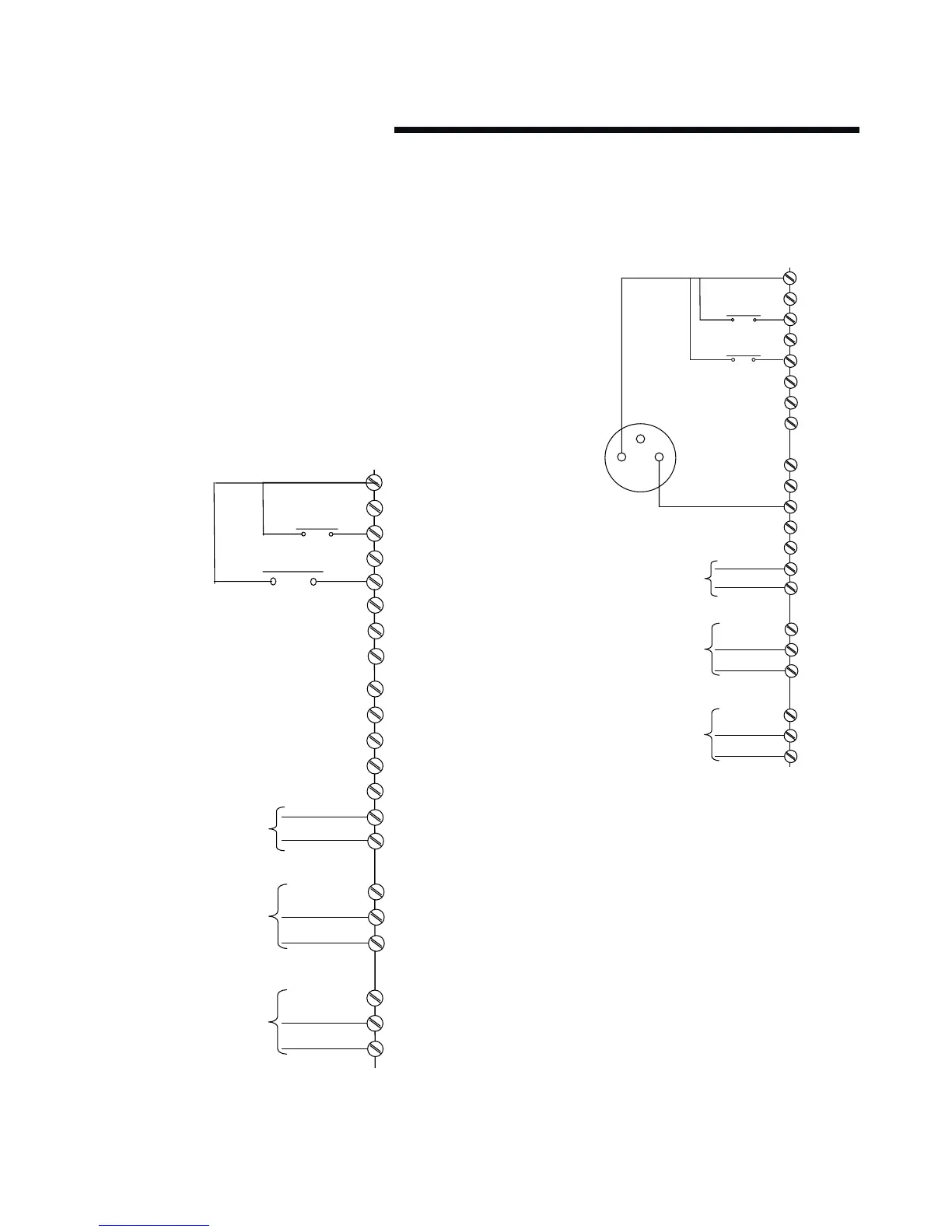

11.8.3 connection examples

Design Envelope pumps can be configured in four main ways:

i Sensorless

ii Closed loop – with feedback sensor

iii Constant curve mode – Potentiometer Control

iv Constant curve mode – bms signal

iv.i Full speed override

i sensorless

Design Envelope pumps are factory configured to be

connected as shown below.

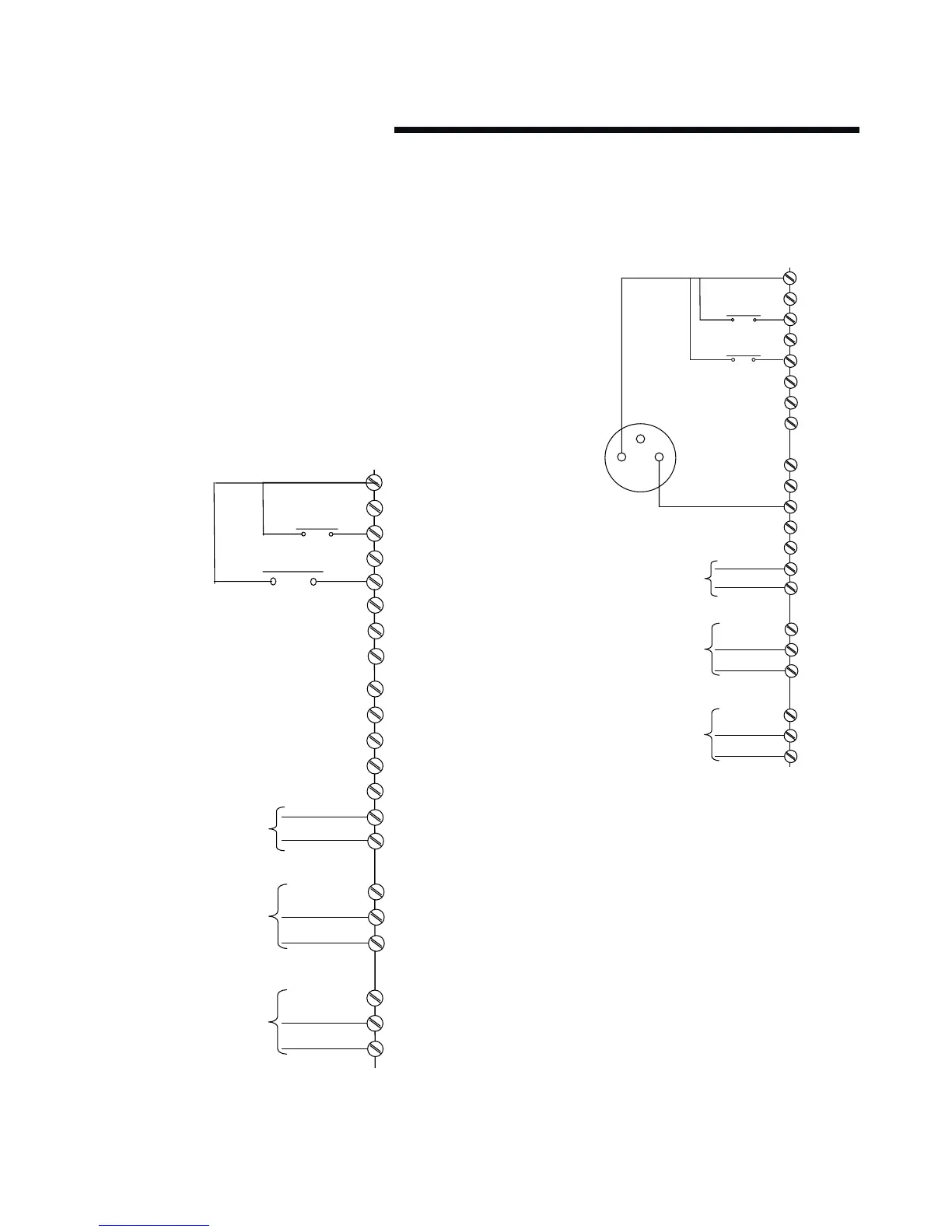

ii closed loop – with sensor feedback

To control the pump based on a 4-20mA feedback signal

from a sensor use the following connection.

12 (+24v )

20 (0v )

18 (d in)

Start Signal

Output Frequency

4-20mA Analog ue Out

Running Output

Alarm Output

19 (

(

d

d

in

in

)

)

50 (10v)

53 (Ain)

54 (Ain)

55 (0v )

42 (Aout)

39 (Aout)

2 (r1 n/o)

3 (r1 n/c)

1 (r1 com)

5 (R2 N/O)

6 (R2 N/C)

4 (R2 COM)

29 (d in)

32 (d in)

33 (d in)

27

24v

12 (+24v )

20 (0v )

18 (d in)

Start Signal

Output Frequency

4-20mA Analogue Out

Running Output

Alarm Output

19 (d in)

27 (d in)

29 (d in)

32 (d in)

33 (d in)

50 (10v)

53 (Ain)

54 (Ain)

55 (0v )

42 (Aout)

39 (Aout)

2 (r1 n/o)

3 (r1 n/c)

1 (r1 com)

5 (R2 N/O)

6 (R2 N/C)

4 (R2 COM)

Pressure Sensor

(0-10 bar / 4 -20ma)

Feedback from Sensor

4-20mA - Input t54

Power Supply (24 vdc)

for sensor t13=24v

Loading...

Loading...