23

7.0 sensorless operation

Sensorless control is an innovative concept in glanded circulat-

ing pumps. Pump performance and characteristic curves for ten

dierent speeds are embedded in the memory of the speed con-

troller during manufacture. This data includes power, pressure

and flow across the flow range of the pump. During operation,

the power and speed of the pump are monitored, enabling the

controller to establish the hydraulic performance and position in

the pumps head-flow characteristic.

These measurements enable the pump to continuously identify

the head and flow at any point in time, giving accurate pressure

control without the need for external feedback signals. Patented

software technology within the controller ensures trouble-free

operation in all conditions. Incorporating the pumps hydraulic

data into the controller and removing sensors results in true

integration of all components and removes the risk of

sensor failure.

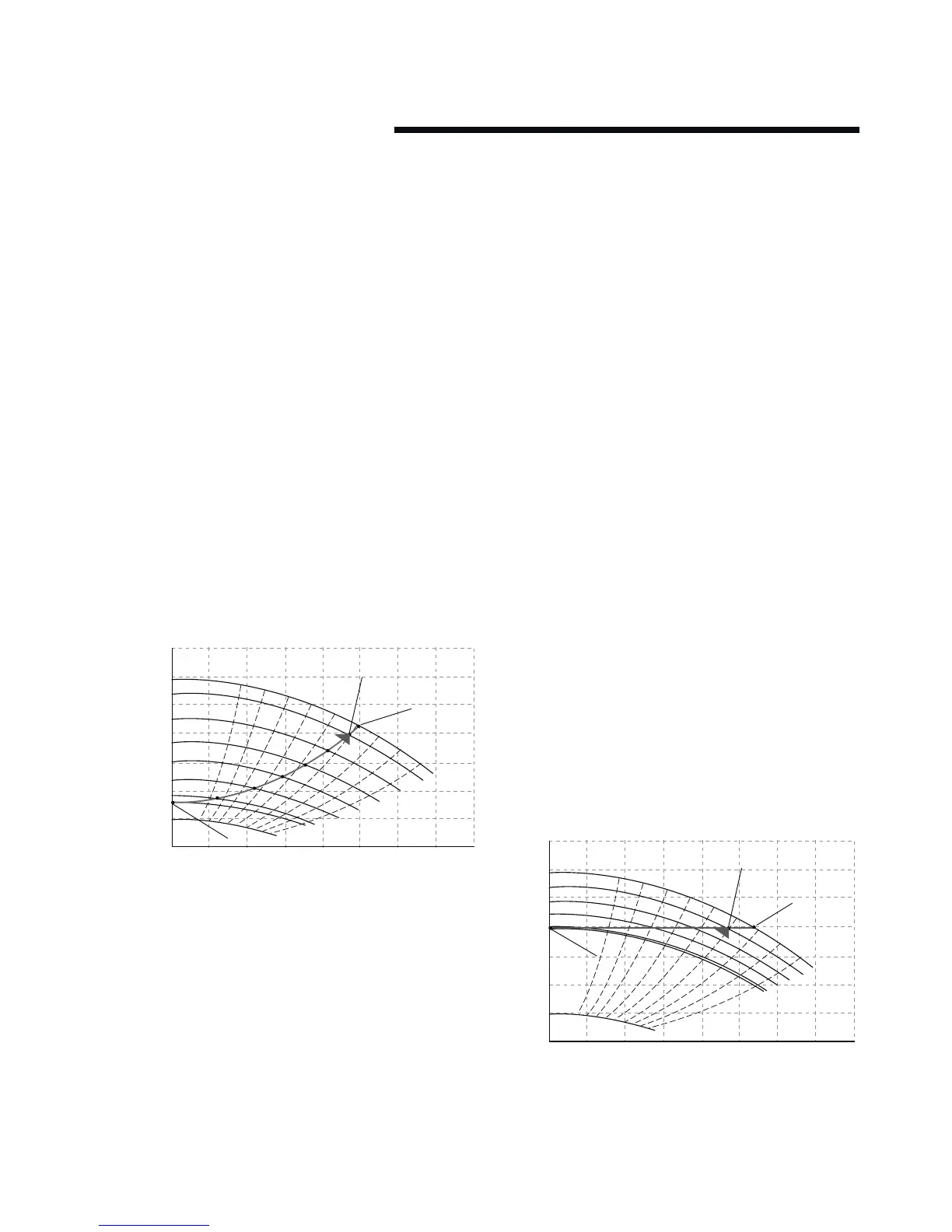

7.1 default operating mode - quadratic

pressure control

The default control mode for Design Envelope pumps ‘Quadratic

Pressure Control’ where the controller is set to control the speed

according to a ‘control curve’ between max and min flow

(see above diagram). It is widely recognised that fitting a

dierential pressure sensor at the most remote load, across the

supply piping and return piping encompassing the valve & coil

set, is the best installation scheme for energy eciency.

Design Envelope pumps can replicate this control without the

need for the remote sensor. As the flow required by the system

is reduced, the pump automatically reduces the head developed

according to the pre-set control curve. It is often found that us-

ing a remote dierential pressure sensor to sense the pressure

across a remote load could theoretically result in loads close to

the pump being underpumped.

The situation would be where the load at a loop extremity is

satisfied and the control valve closes while a load close to the

pump needs full flow.

The probability of this occurring is remote but it is possible. One

answer to this is to move the sensor closer to the pump (two-

thirds out in the system is a popular recommendation) although

physically re-positioning the sensor at commissioning stage can

be a costly exercise. With Sensorless pump control it is possible

to replicate the moving of a sensor by adjusting the head setting

‘Head Q

min

’.

7.1.1 description of settings

The design duty head and flow of the pump (provided at time of

order) is defined by the controller as ’head working point’ and

’flow working point’. The minimum head (Head Q

min

) is defined

as a percentage of the head working point. The maximum

controllable head (Head Q

max

) is the head developed when the

pump reaches full speed and is calculated by the other two

head settings.

7.1.2 setting parameters for quadratic

pressure control

• Parameter 716 - Enter the head (kPa) at design flow.

•

Parameter 717

- Enter the design flow (l/s).

•

Parameter 707

- Enter the minimum head requirement

(as a percentage of p716).

• Parameter 705 - Quadratic Head should be set to ’on’.

•

Parameter 798

- This is a calculated value from the

settings above and should not be changed.

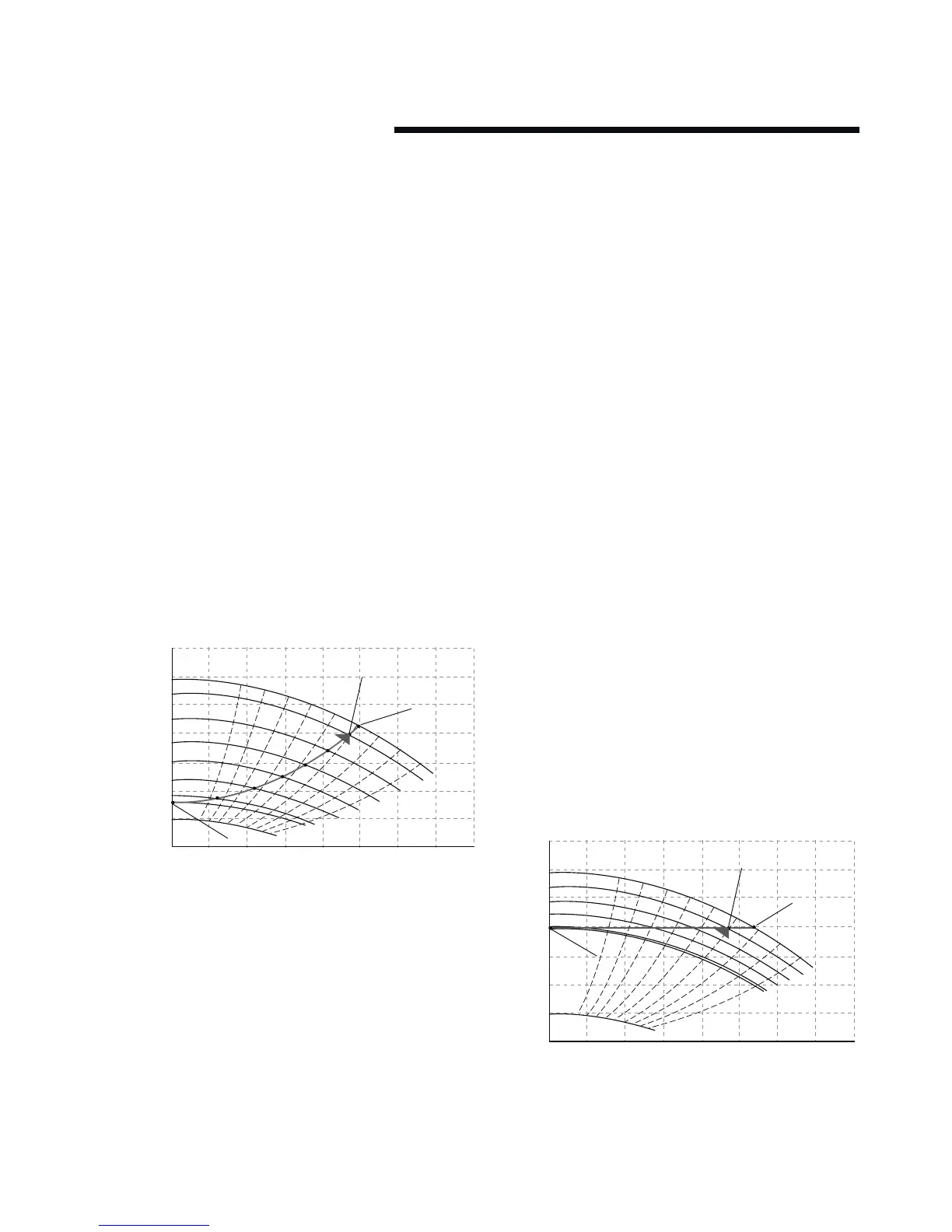

7.2 constant pressure control

Design Envelope pumps can be configured to maintain a con-

stant pressure in a system as the demand varies. This eectively

simulates the mounting of a dierential pressure sensor at, or

near, the pump.

0

0

20

40

60

80

100

120

10

51

1450 rpm

1388 rpm

1270 rpm

1150 rpm

1040 rpm

920 rpm

801 rpm

750 rpm

580 rpm

62

71

77

81

82

81

77

1

2

3

4

5

6

7

71

20 30 40 50 60 70 80

flow – L/s

water, spgr= 1.0000

Loading...

Loading...