24

7.2.1 setting parameters for constant

pressure control

• Parameter 716 - Enter the head (kPa) at design flow.

•

Parameter 717

- Enter the design flow (l/s).

•

Parameter 707

- Enter the minimum head requirement

(as a percentage of p716). which will be 100% for

constant pressure.

• Parameter 705 - Quadratic Head should be set to ’off’.

•

Parameter 798

- This is a calculated value from the

settings above and should not be changed.

7.3 proportional pressure control

Where a linear reduction in head is required with reducing flow

then the quadratic curve should be turned o.

7.3.1 setting parameters for

proportional pressure control

• Parameter 716 - Enter the head (kPa) at design flow.

•

Parameter 717

- Enter the design flow (l/s).

•

Parameter 707

- Enter the minimum head requirement

(as a percentage of p716).

• Parameter 705 - Quadratic Head should be set to ’off’.

•

Parameter 798

- This is a calculated value from the

settings above and should not be changed.

8.0 control using external feedback

(closed loop control).

Design Envelope pumps can be configured (using the keypad) to

accept a feedback signal from a remote sensor (e.g. temperature

transmitter for constant temperature). The connection of an

external device will depend on the device itself although typical

devices are 4-20mA, 2 wire where the supply will be provided by

24v dc on terminal 6 of x101 and the output signal connected to

terminal 1 of x101.

The parameter list following this section gives typical settings

for closed loop control.

8.1 parameter groups and descriptions.

group 0 – operation and display.

Language/Local Control – Parameters 001,002, 003

Not normally changed.

Active Set-up – Parameter 004

It is possible to program two separate sets of data for controlling

the inverter.

Program Set-up – Parameter 005

The active set-up can be either set-up 1, set-up 2 or can be

remotely switched between the two.

Copying of Set-ups – Parameter 006

A copy is made from the set-up selected in parameter 005

and copied to the set-up selected in parameter 006.

Copying of Set-ups Between Inverters – Parameter 007

• Connectkeypadtotheinverterfromwhichthedesired

set-up is to be copied.

• Select1inparameter007 to upload all parameters into the

key pad.

• Connectkeypadtotheinvertertowhichthedesiredset-up

is to be copied.

• Select3 in parameter 007 to download all parameters into

the inverter.

• Byselecting3 in parameter 007, copying from one size of

inverter to a dierent size will not aect the power settings.

Display Scaling – Parameter 008

Multiplication factor of frequency (normally set at 1).

Display Configuration – Parameters 009-012

Allows choice of data to displayed in lines 1 and 2 of the key pad.

Local Operations – Parameters 013 -019

Not normally changed.

group 1 – load and motor.

Configuration – Parameter 100

Sets the configuration under which the inverter is controlled.

attention:

Set to Process Closed Loop for control via the 4 -20mA trans-

ducer feedback input set to Speed Open Loop for Potentiometer,

bms or Sensorless control.

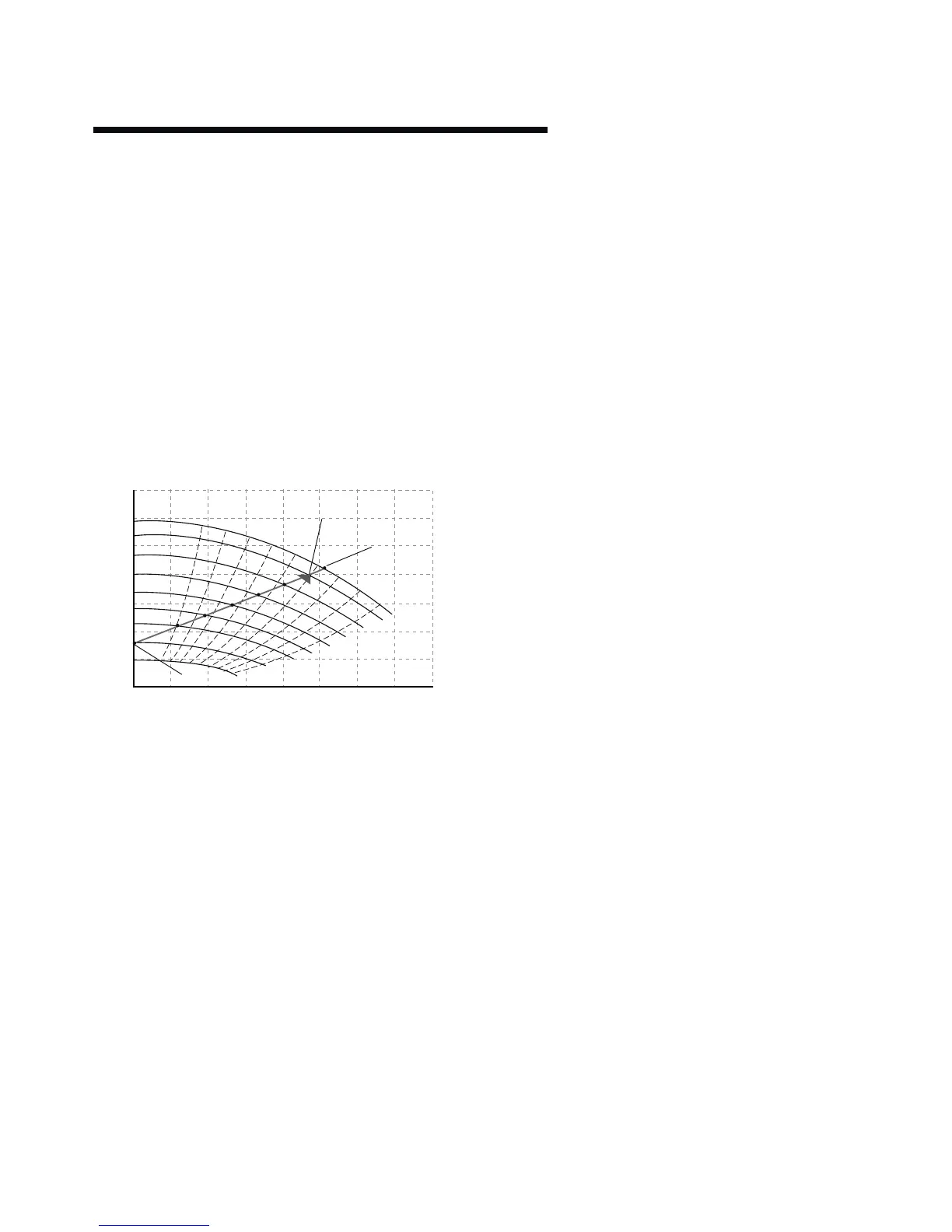

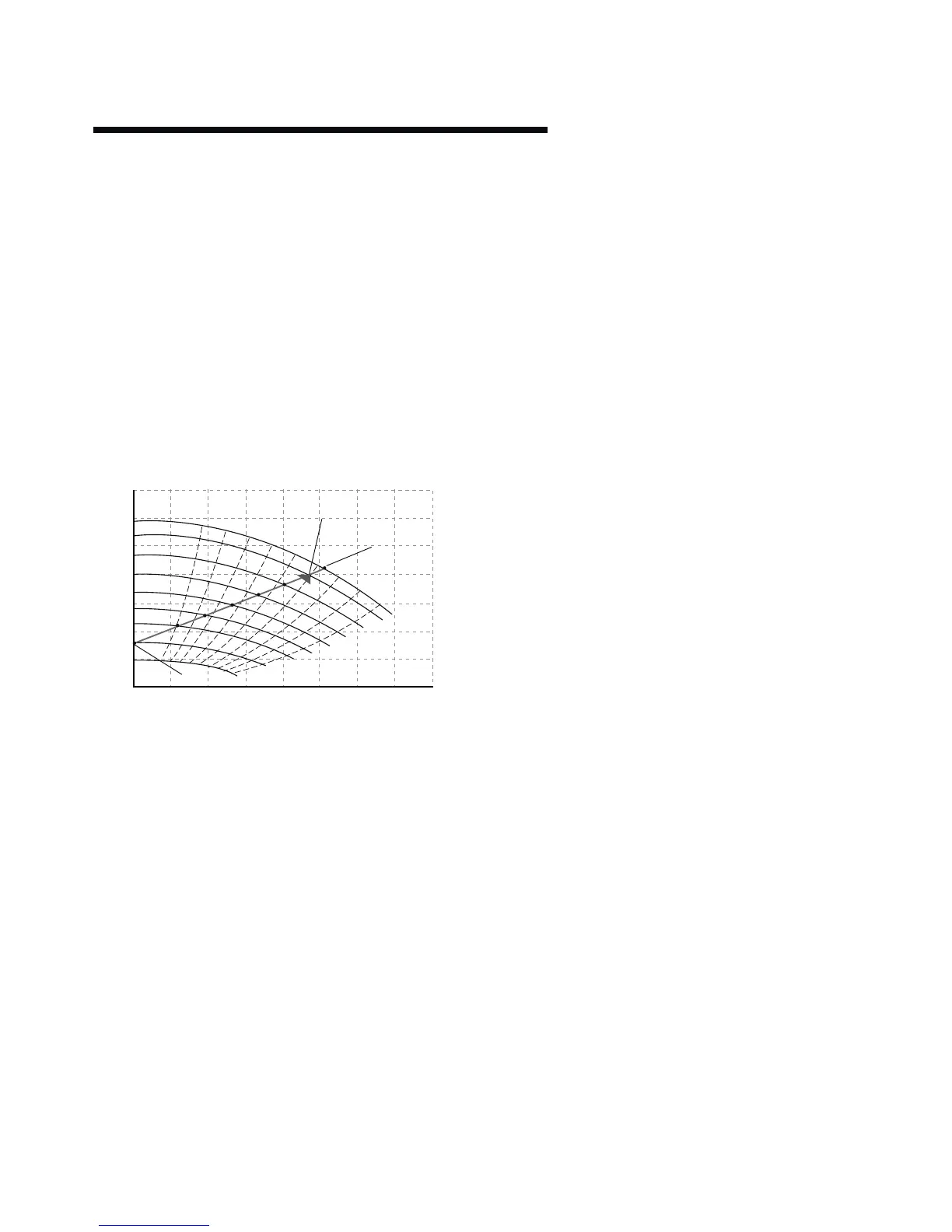

0

0

20

40

60

80

100

120

10

51

1450 rpm

1388 rpm

1290 rpm

1190 rpm

1090 rpm

990 rpm

894 rpm

750 rpm

580 rpm

62

71

77

81

82

81

77

1

2

3

4

5

6

7

71

20 30 40 50 60 70 80

Loading...

Loading...