19

Control key functions

[display / status] is used for selecting the mode of

display or for changing back to Display mode from

either the Quick menu mode or the Menu mode.

[quick menu] is used for programming the param-

eters that belong under the Quick menu mode. It

is possible to switch directly between Quick menu

mode and Menu mode.

[menu] is used for programming all parameters. It is

possible to switch directly between Menu mode and

Quick menu mode.

[change data] is used for changing the parameter

selected either in the Menu mode or the Quick

menu mode.

[cancel] is used if a change of the selected

parameter is not to be carried out.

[ok] is used for confirming a change of the

parameter selected.

[+/-] is used for selecting parameter and for

changing the chosen parameter or for changing the

read out in line 2.

[<>] is used for selecting group and to move the

cursor when changing numerical parameters.

[stop / reset] is used for stopping or for resetting

the pump after a drop-out (trip). Can be selected

via parameter 014 to be active or inactive. If stop is

activated, line 2 will flash, and [start] must

be activated.

attention:

Pressing [stop/reset] will prevent the pump from running also

with disconnected lcp. Restarting is only possible via the lcp

[start] key.

[jog] overrides the output frequency to a preset

frequency while the key is kept down. Can be

selected via parameter 015 to be active or inactive.

[fwd / rev] changes the direction of rotation of the

motor, which is indicated by means of the arrow on

the display although only in Local. This key is

inactive by default.

[start] is used for starting the pump after stop via

the [stop] key. Is always active, but cannot override

a stop command given via the terminal strip.

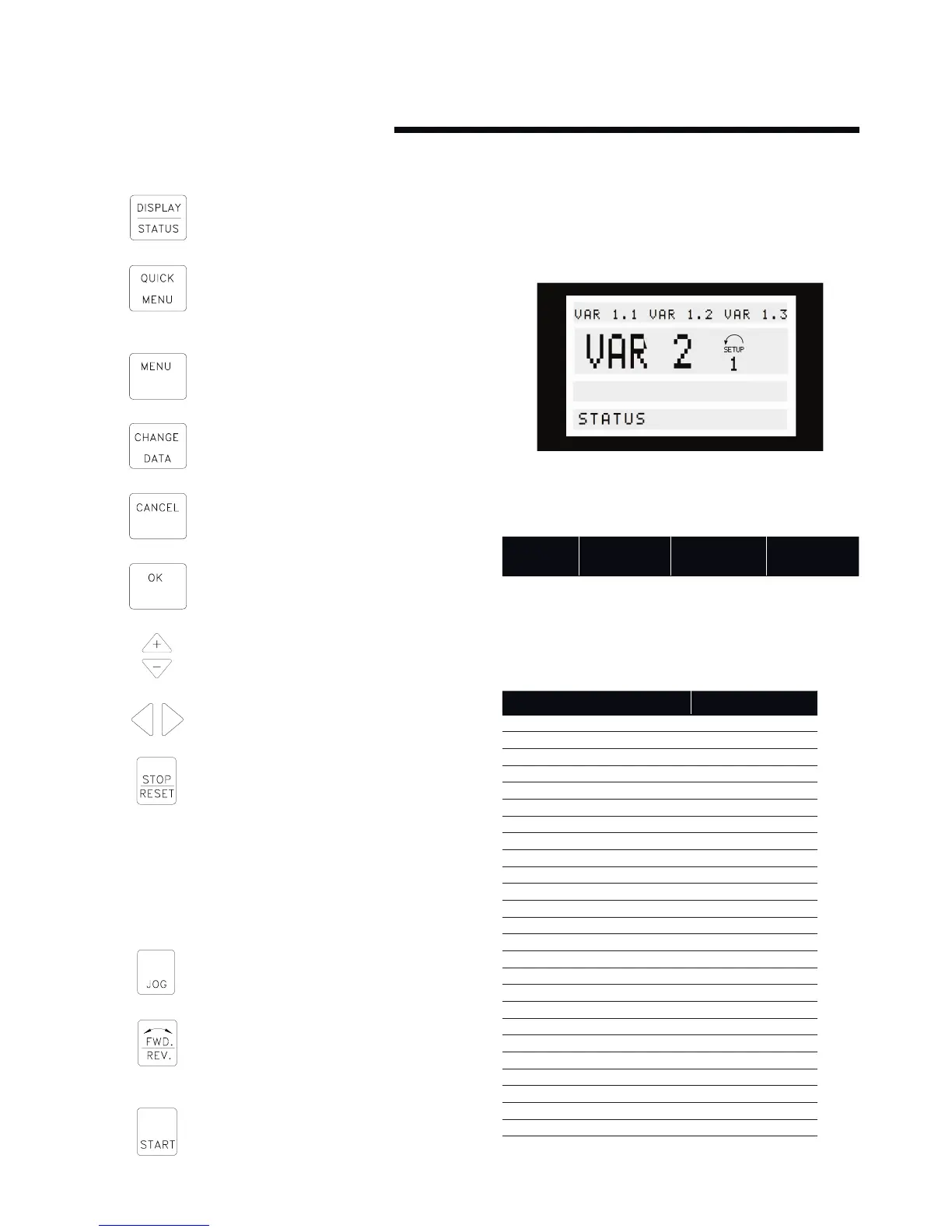

6.1.4 display mode

In normal operation, up to 4 dierent operating variables can be

indicated continuously: 1,1 and 1,2 and 1,3 and 2, and in line 4 the

present operating status or alarms and warnings that have arisen.

There are three options in connection with the choice of read

-out state in the Display mode - I, II and III. The choice of read-

out state determines the number of operating variables read out.

read-out

state:

i ii iii

Line 1 Description for

operating vari-

able in line 2

Data value for 3

operating vari-

ables in line 1

Description

for 3 operating

variables in line 1

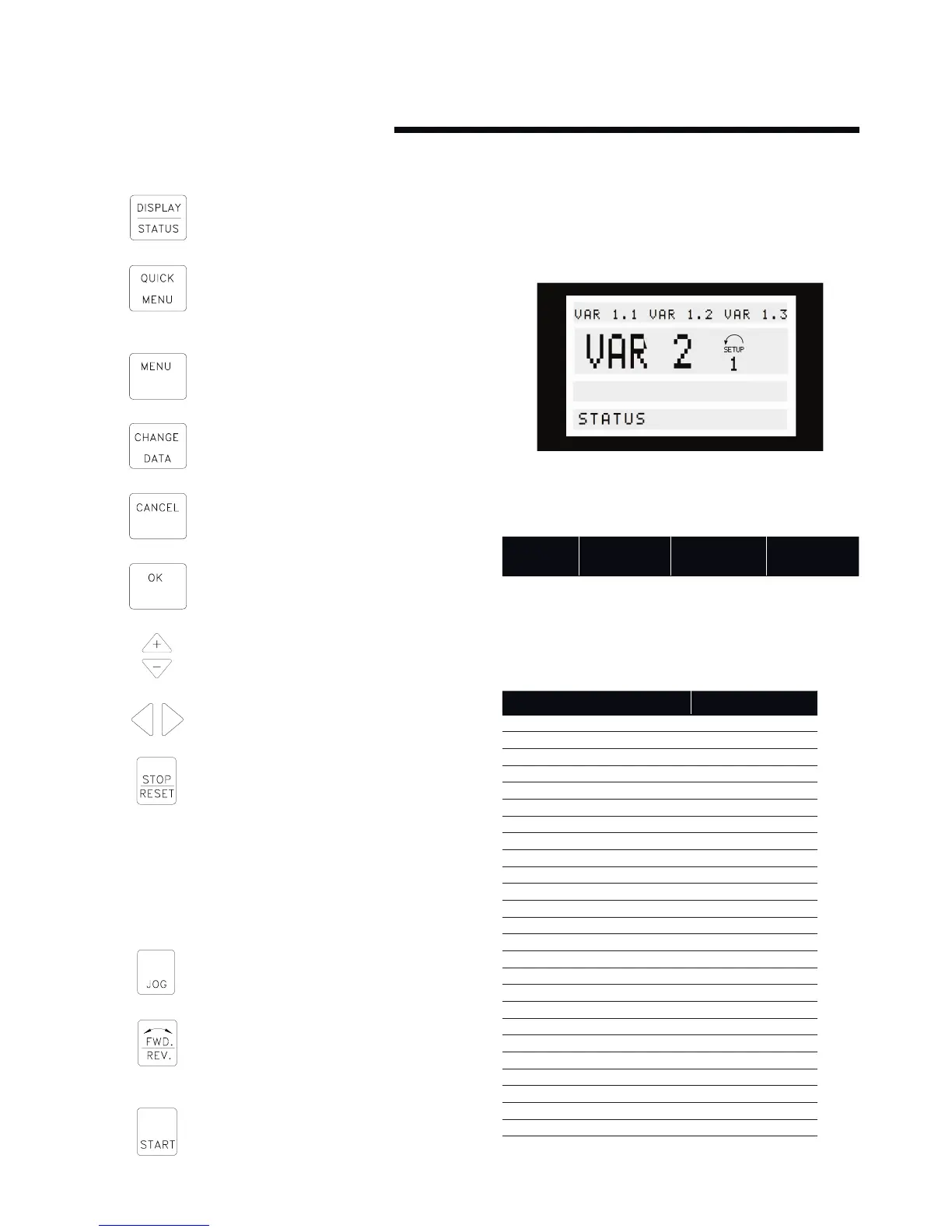

The table below gives the units linked to the variables in the first

and second line of the display (see parameter 009).

operating variable unit

Reference [%]

Reference [unit]*

Feedback [unit]*

Frequency [Hz]

Frequency x scaling [-]

Motor current [A]

Torque [%]

Power [kW]

Power [HP]

Motor voltage [V]

dc-link voltage [V]

fc thermal [%]

Hours run [Hours]

Input status, dig. Input [Binary code]

External reference [%]

Status word [Hex]

Heat sink temp. [°c]

Alarm word [Hex]

Control word [Hex]

Warning word 1 [Hex]

Warning word 2 [Hex]

Analog input 1 [mA]

Analog input 2 [V]

Sensorless power [W]

Sensorless flow [l/s]

Sensorless head [kPa]

* Select in parameter 416. The unit is shown in readout

state 1 line 1 otherwise ’U’ is shown.

Loading...

Loading...