Preamble

UM-23100B-U User manual ATEQ F CLASS Page 6/90

3. THE MAIN TYPES OF MEASUREMENTS

There are three measurement methods:

Direct measurement, indirect measurement and sealed component measurement.

These three methods apply to measurements taken both under pressure and in vacuum

conditions.

The configuration is determined by the application and must be carried out prior to the

use of the instrument.

3.1. DIRECT/PRESSURE DROP MEASUREMENT

After filling the test and reference parts to the required pressure level, the ATEQ F

CLASS measures the differential pressure between the two volumes which are

separated by the equalisation valve.

At the end of a cycle, the ATEQ empties the components via the dump valve.

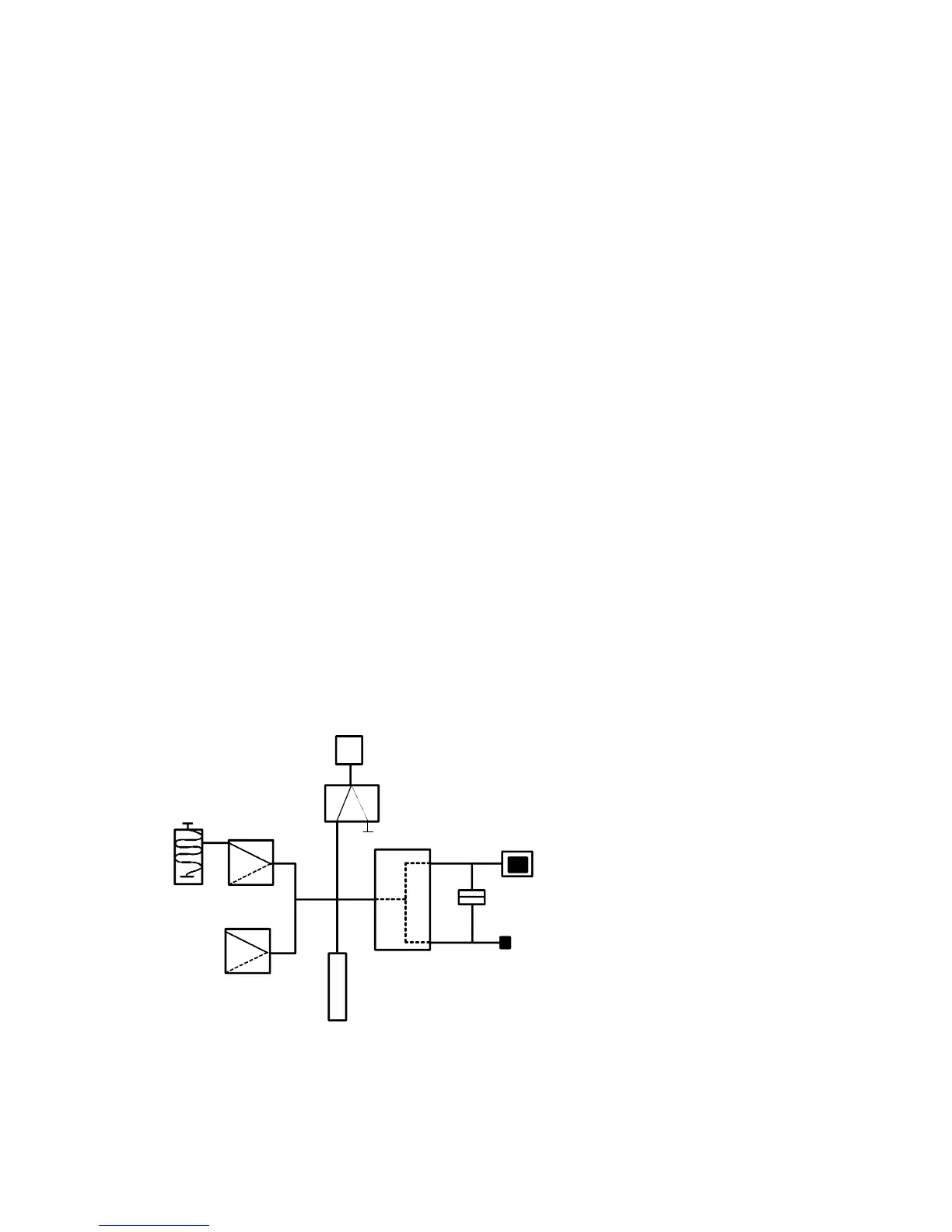

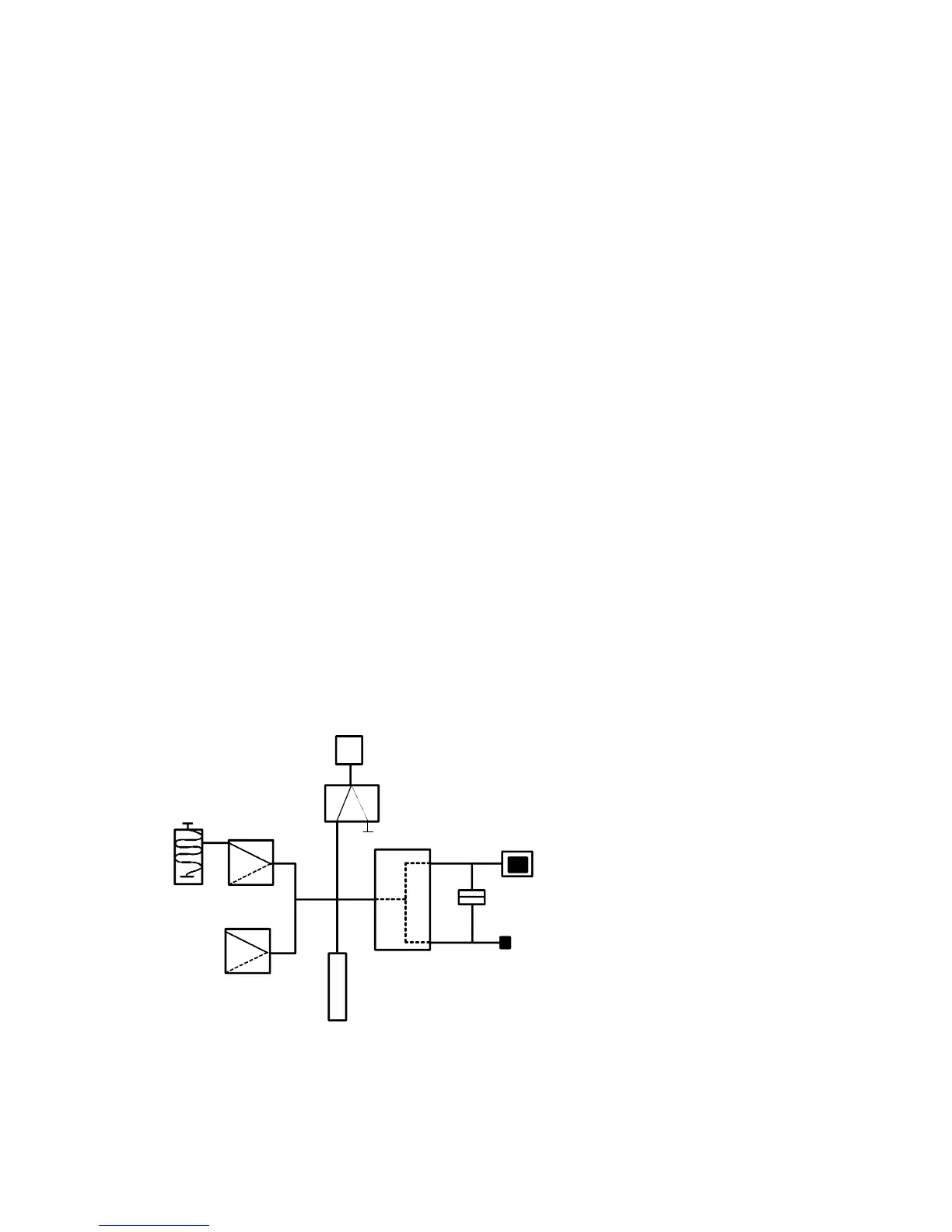

3.2. INDIRECT/ PRESSURE RISE MEASUREMENT

The test part is placed in a sealed bell and the ATEQ F CLASS is pneumatically

connected to the bell. The part is externally pressurised (with up to 20 MPa or 200 bar),

and the bell is lightly pressurised. In the event of a part leakage, the pressure in the bell

will rise. This method allows certain parts to be tested at high pressure levels whilst

avoiding the associated constraints. The ATEQ F CLASS only tests and measures the

pressure in the bell. In the event of a large leak, electronic monitoring of the pressure in

the bell will switch the instrument to safety.

3.3. SEALED COMPONENT MEASUREMENT

INTERNAL VOLUME

FILL

VALVE

REGULATOR

DUMP VALVE

ELECTRONIC

PRESSURE SWITCH

REFERENCE PART

SEALING CONNECTOR

BELL

PART

SENSOR

This test is for hermetically

sealed parts, which can not be

filled. They are placed inside a

bell which is pressurised.

The first and the third measurements may be carried out in comparison with a

reference, without reference or in central zero.

Loading...

Loading...