Chapter 4 – Functions of the instrument

UM-23100B-U User manual ATEQ F CLASS Page 53/90

2.1.3. 11) Mini valve

This function is dedicated to applications for small volume parts (below 10 cm

3

) and has

a base time of 0.01s instead of 0.1 s.

Programming for the

ATEQ F CLASS with mini valve is identical to that for the standard

ATEQ F CLASS.

Parameters to be set are: A-Z Diff (differential Auto Zero).

)Select the option and enter settings if necessary.

2.1.3. 12) Recovery limits

This option offers the option of two reject levels: non-tolerance level (the bad part is not

recoverable) and recoverable reject level (the part is bad but may be reworked to

become acceptable. This option is particularly used in casting, when parts are intended

for treatment via impregnation. )

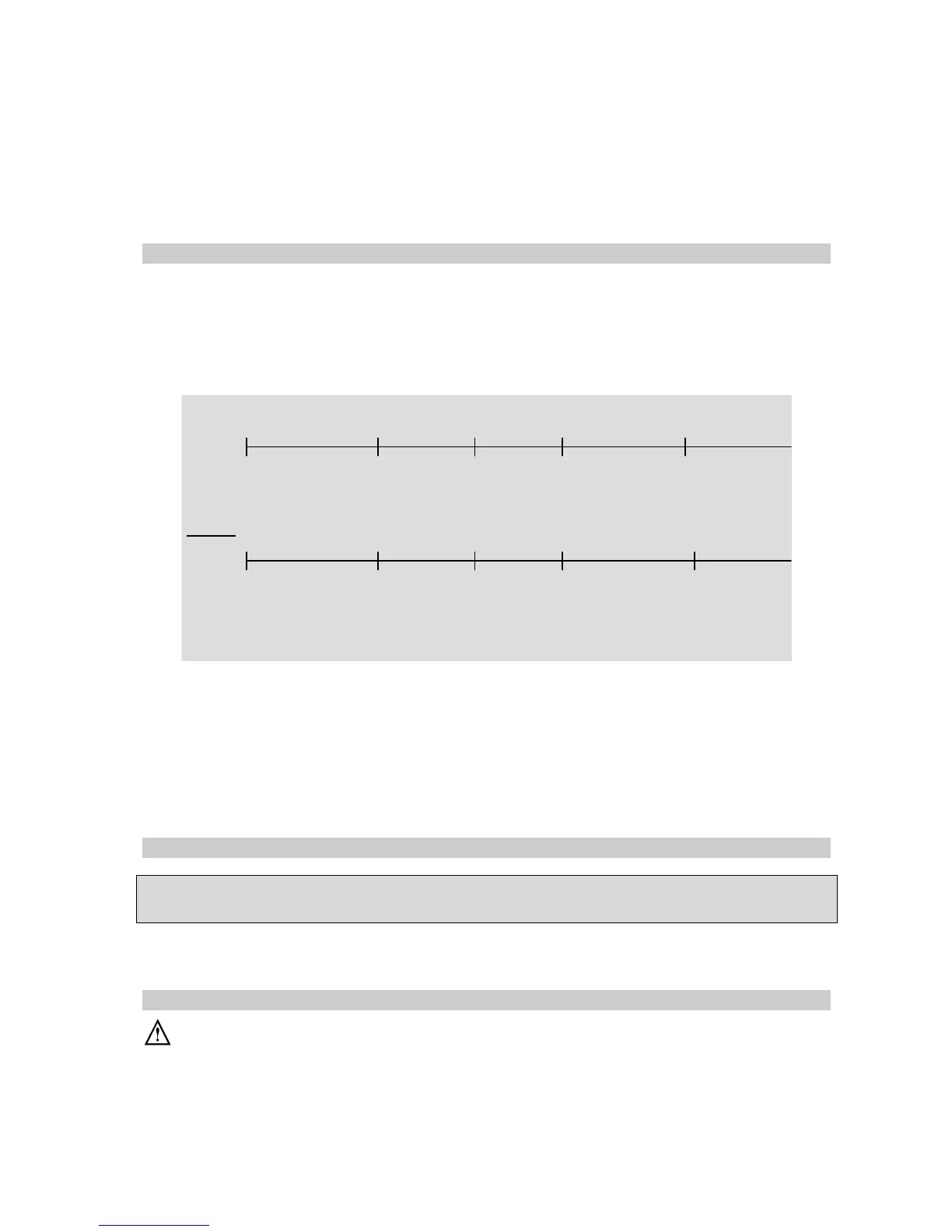

REFERENCE

REJECT LEVEL

REJECT REFERENCE

RECOVERY LEVEL

0

TEST REJECT

RECOVERY LEVEL

TEST REJECT LEVEL

PARTS

GOOD

PARTS

RECOVERABLE

PARTS

BAD

0 10 20

Example

0 TO 10 OF THE PARTS ARE GOOD

10 TO 20 OF THE PARTS ARE RECOVERABLE

BOVE 20 THE PARTS ARE NOT RECOVERABLE

The associated parameters to be set are: RECUP Test, RECUP Ref.

For recoverable parts, with multi-head configuration on the central unit or on the heads

themselves, the Pass (PB) and Fail (PM) outputs are both activated simultaneously. .

Note: when the recoverable reference reject value is zero, the program uses the

symmetrical absolute value of the recoverable test reject (e.g.: if the recoverable test

reject is 10 Pa, then with the recoverable reference reject value equal to zero, the

program takes the recoverable reference reject to be – 10 Pa).

) Select the option and enter settings if necessary.

The instrument allows for variations in input pressure. This is why the

maximum and minimum parameters vary for each cycle.

Learning cycles for good parts and parts with a large leak are accessed through the

main menu, special cycles.

)Select the option and enter settings if necessary.

Test cycles can not be carried out unless learning cycles have previously been

carried out.

Loading...

Loading...