Model X High Speed Sublimation printer

60

55 ~ 70%).

2. Check if the negative pressure is correct, if there is ink hanging, and if there is air in the

pipeline.

3. Check whether the nozzle has rubbed into the medium and process in time.

4. Check whether the blade is worn or deformed and replaced in time.

5. Print a whole test strip, the width is 0.2cm, and observe the clogged condition in time.

6. Problem of nozzle itself (temperature out of control, scratch).

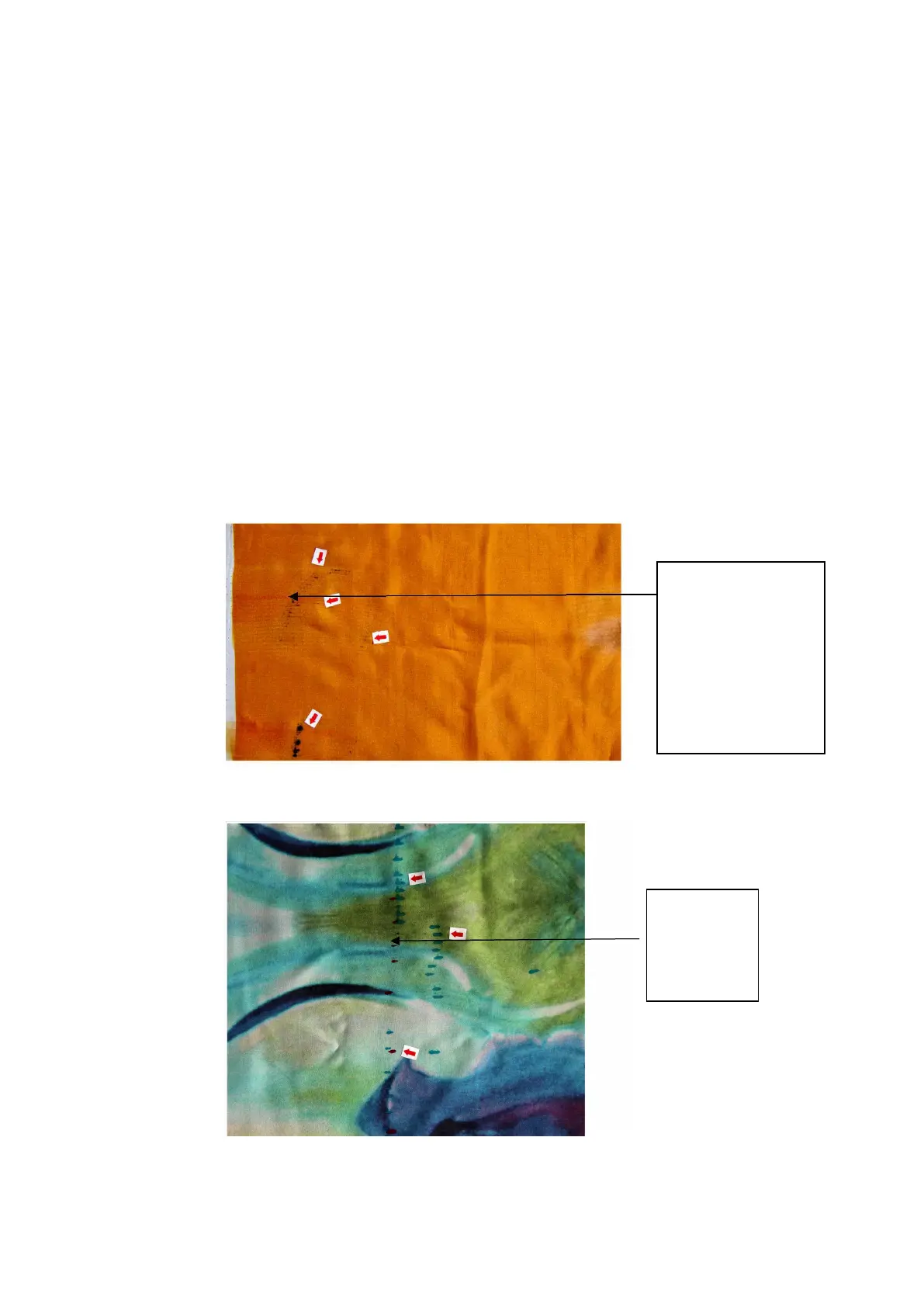

7.9 Medium fouling

(1) Rubbing nozzle: mainly caused by wrinkles on the medium during printing. At present,

all machines have limited high protection devices. When the medium is wrinkled, the

machine will automatically stop printing after the height limit is touched. The pattern

can be continued after processing.

Figure 7-5

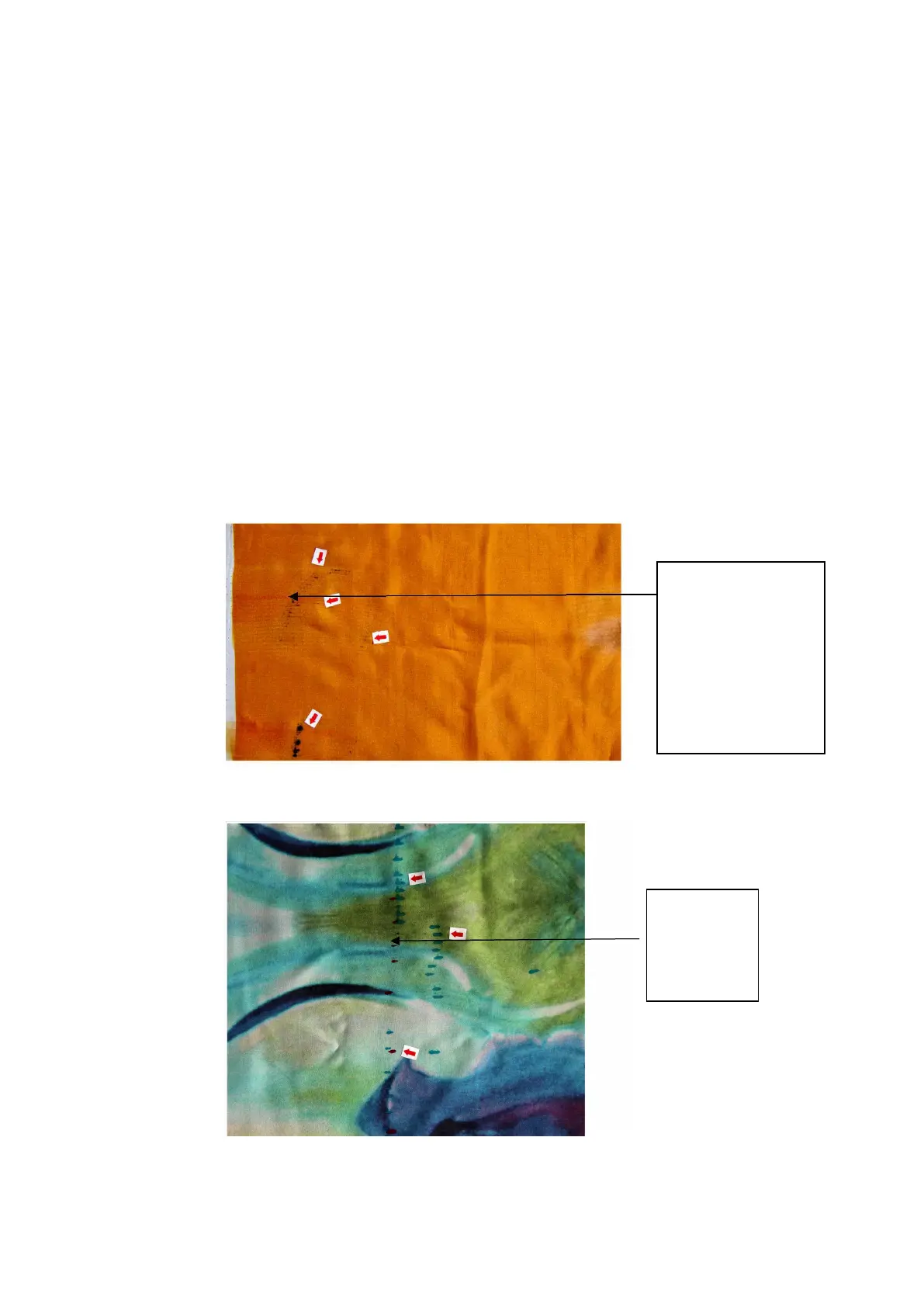

(2)Dropping ink

Figure 7-6

The black dot

indicated by the

arrows is the nozzle

rubbing against the

printing surface

The arrows

point to the

ink drop on

the paper.

Loading...

Loading...