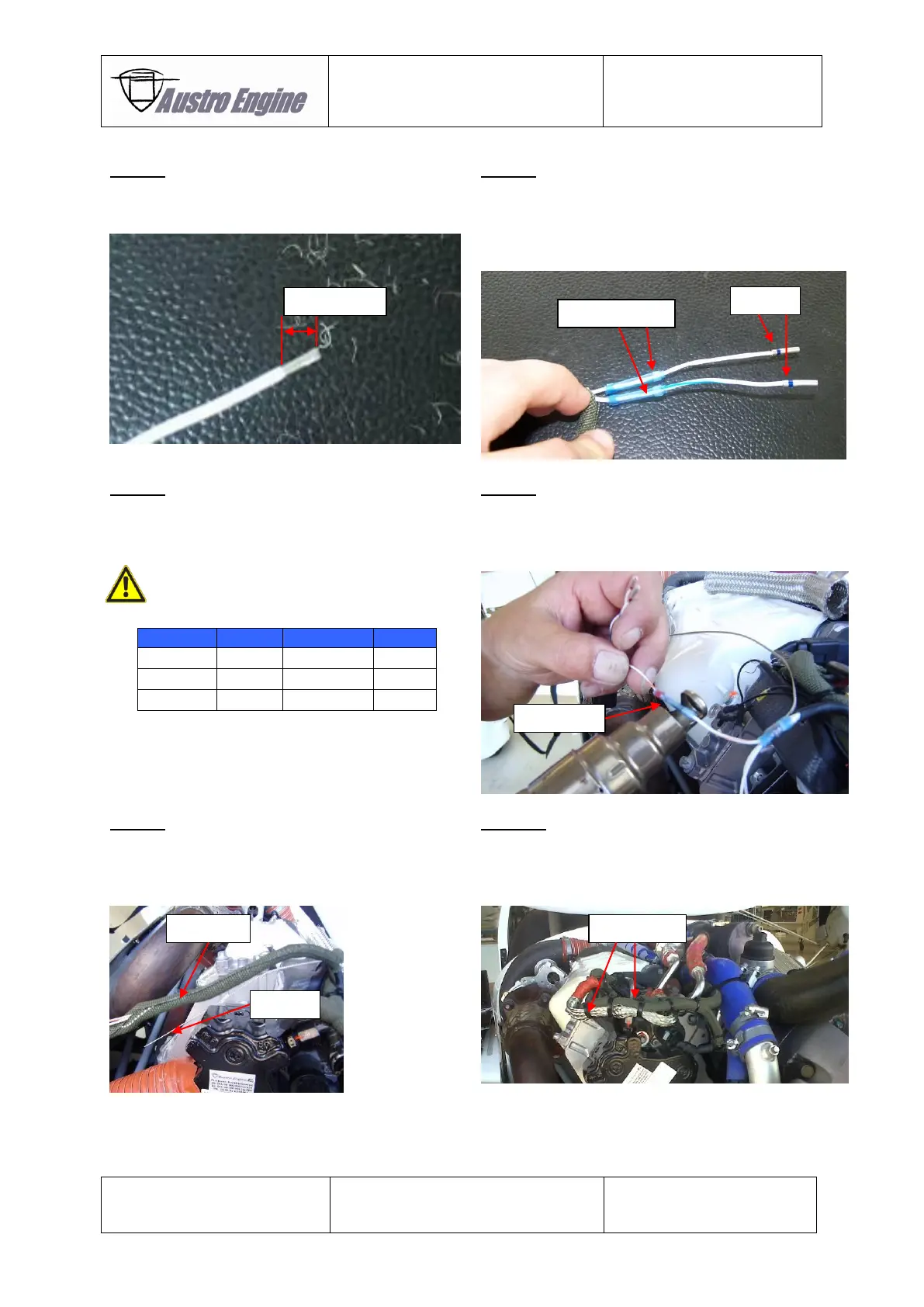

Step 5:

Remove the isolation of all single wires on the end

of the engine harness and the repair kit cable E4A-

90-R18-000 as shown below.

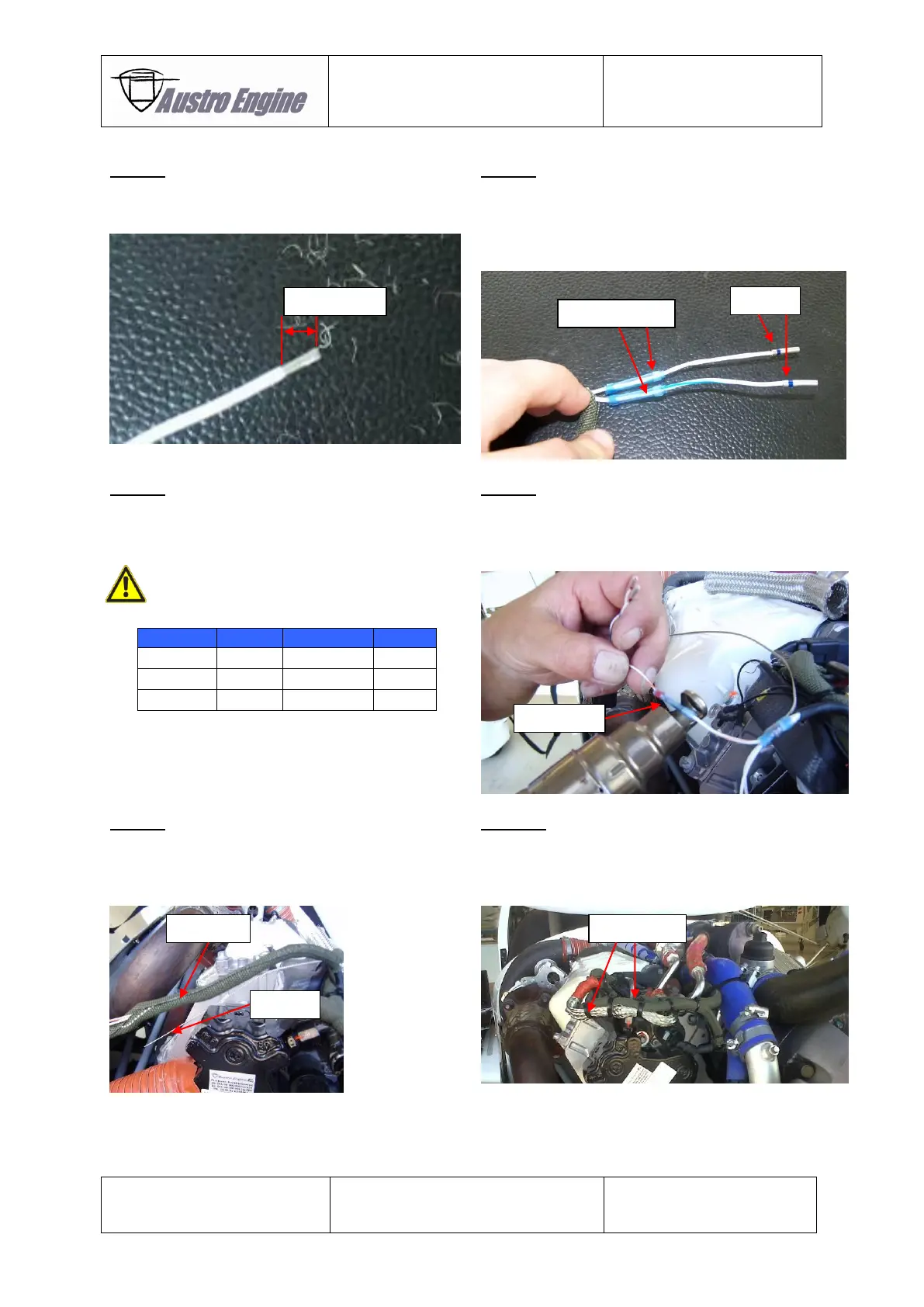

The inline crimp consists of the splice crimp and the

isolation sleeve. Put the isolation sleeve of the inline

crimp over the single wire of engine harness.

Place the splice crimp at the end of the single wires

of the repair kit cable E4A-90-R18-000.

Connect the singles wires of the engine harness

with the repair kit cable of E4A-90-R18-000 by

usage of the inline crimp.

Pinning list for FPS connector is shown in

the table below.

Put the isolation sleeve of the inline crimp over the

inline crimp sleeve. Heat the isolation sleeve (300°C

– 350°C) with a hot air gun until the isolation sleeve

seals the splice crimp and the single wires.

Put the chafing protection ROUNDIT over the

repair kit cable and the engine wiring harness. The

length of the chafing protection ROUNDIT can be

reduced if necessary.

Ensure that the

pig tail is not covered with ROUNDIT and a ring

termination is mounted on it.

Install the additional shielding E4A-95-100-000 as

described in the Installation Manual E4.02.01. The

shielding shall be used as an additional caving

protection.

Cable ties as provided in the repair kit can be used

for fixation.

Loading...

Loading...