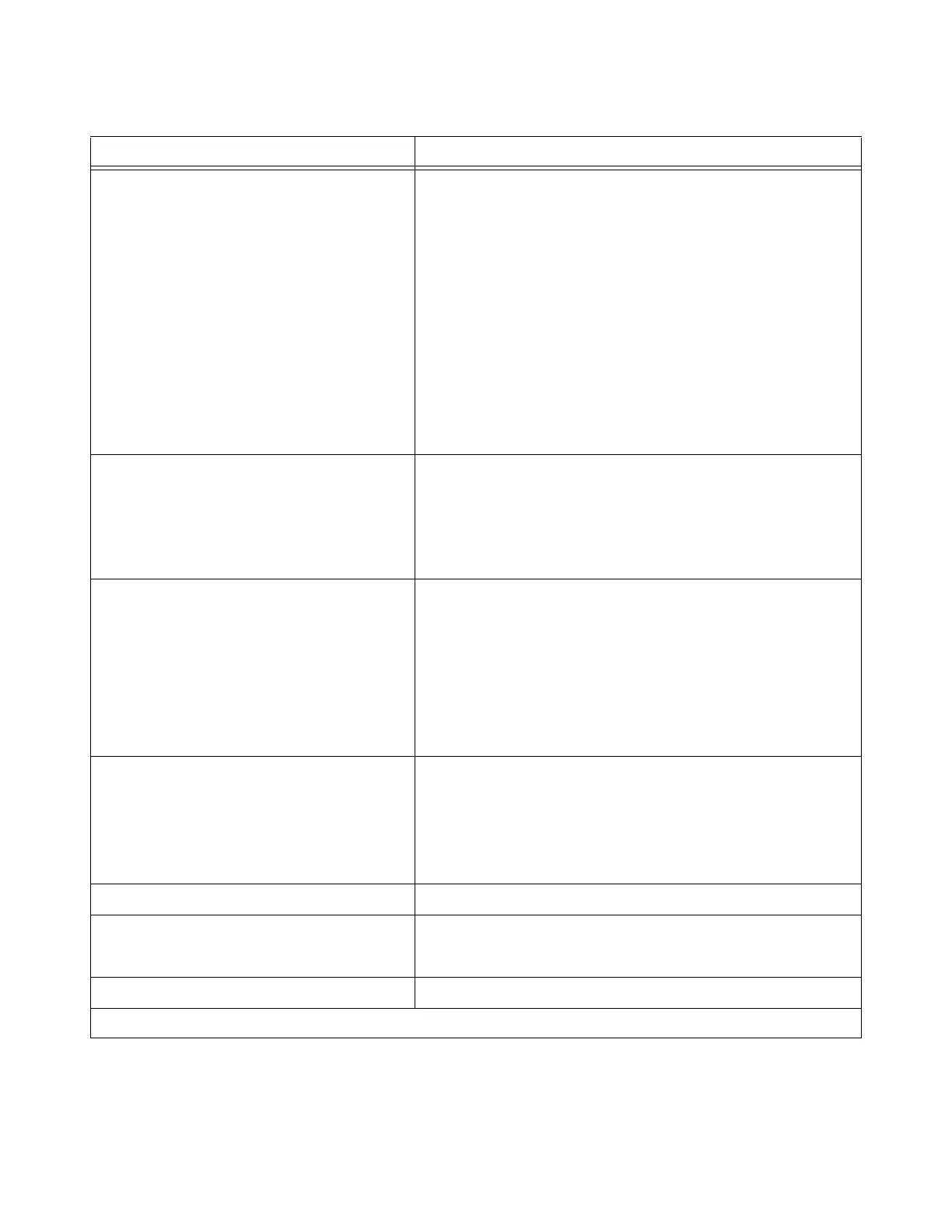

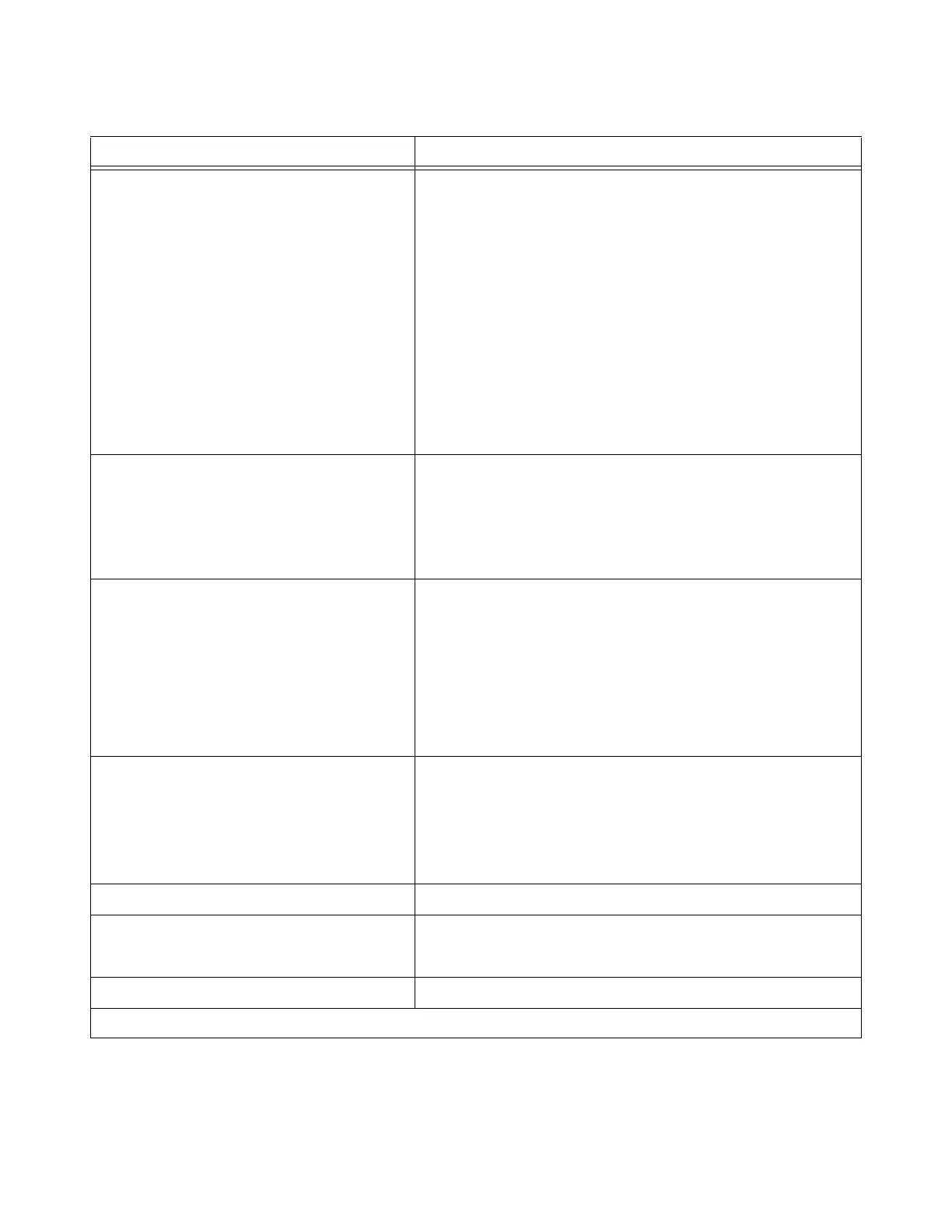

7-6

920512-768 Operator Manual Troubleshooting

8. Load comes out dirty 1. Wrong type of detergent or inappropriate concentration –

Refer to S

ECTION 2.4, CHEMICAL ADDITIVES SPECIFICA-

TIONS, and follow manufacturer's recommendations for

amount of detergent to be used.

2. Horizontal spray jets clogged – Clean spray jets.

3. Wash treatment too short – Increase wash treatment

time. Call STERIS.*

4. Tank reuse counter too high – Reset tank reuse counter

in Service mode (default reuse setting is 20). Call

STERIS.*

5. If condition reoccurs, call STERIS.*

9. If Automatic Floor Tilting option is

present: Automatic floor tilt lifting too

slowly, not lifting, or stays in upper posi-

tion.

1. Load exceeds 800 lb (363 kg) – Verify load weight.

2. Air flow control improperly adjusted – Call STERIS.*

3. Air pressure improperly adjusted – Call STERIS.*

4. If condition reoccurs, call STERIS*.

10. Abnormal draining of wash chamber or

sump overflow.

1. Sump filters clogged – Remove and clean sump filters.

2. Self-cleaning filter cartridge clogged – Clean cartridge.

3. Sump siphoning tubing clogged – Verify and remove

obstruction.

4. Suction pump impeller damaged – Call STERIS.*

5. If condition reoccurs, call STERIS.*

11. Foam in chamber or inside tanks. 1. Wrong type detergent – Refer to S

ECTION 2.4, CHEMICAL

ADDITIVES SPECIFICATIONS, and follow manufacturer's

recommendations for amount of detergent to be used.

2. Too much chemical injected during treatment – Call

STERIS.*

12. Detergent leaks from mechanical core. Call STERIS.*

13. Suction pump abnormally noisy. 1. Sump filters clogged – Remove and clean sump filters.

2. If condition reoccurs call STERIS.*

14. High pressure pump abnormally noisy. Call STERIS.*

* Service charges may be incurred. Consult your warranty for details.

Table 7-3. Troubleshooting Chart – No Alarm or Printout, Mechanical Problems (Cont’d)

PROBLEM POSSIBLE CAUSE AND CORRECTION

Loading...

Loading...