QUICKFIRE® WRAP AROUND

1MANUL825 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 17

Installation

Positioning the Stands (Legs)

Note:

The stands will have to be leveled later during the installation, so do not pound any lag

bolts down all the way into the floor. Shims may also be required in the leveling process

although they are not supplied.

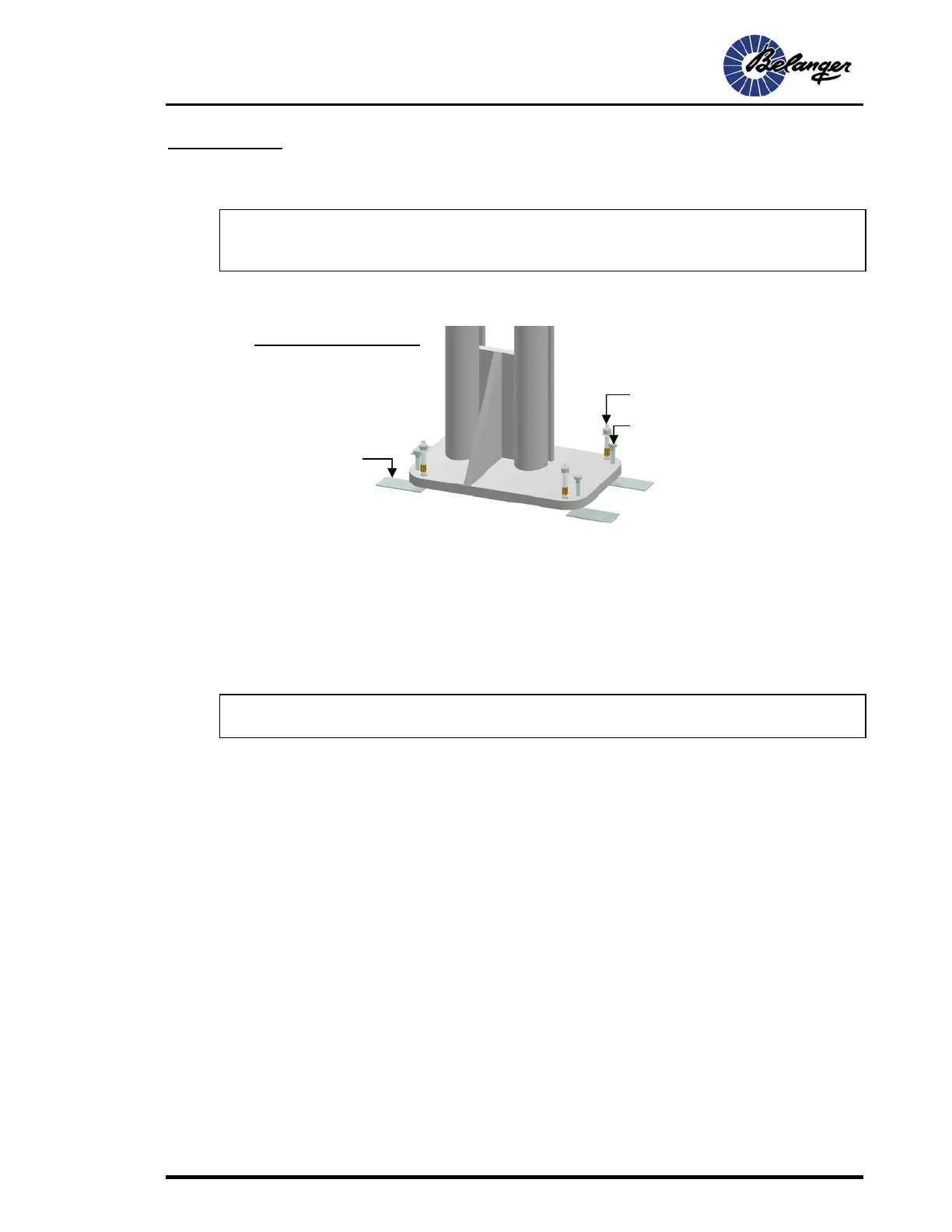

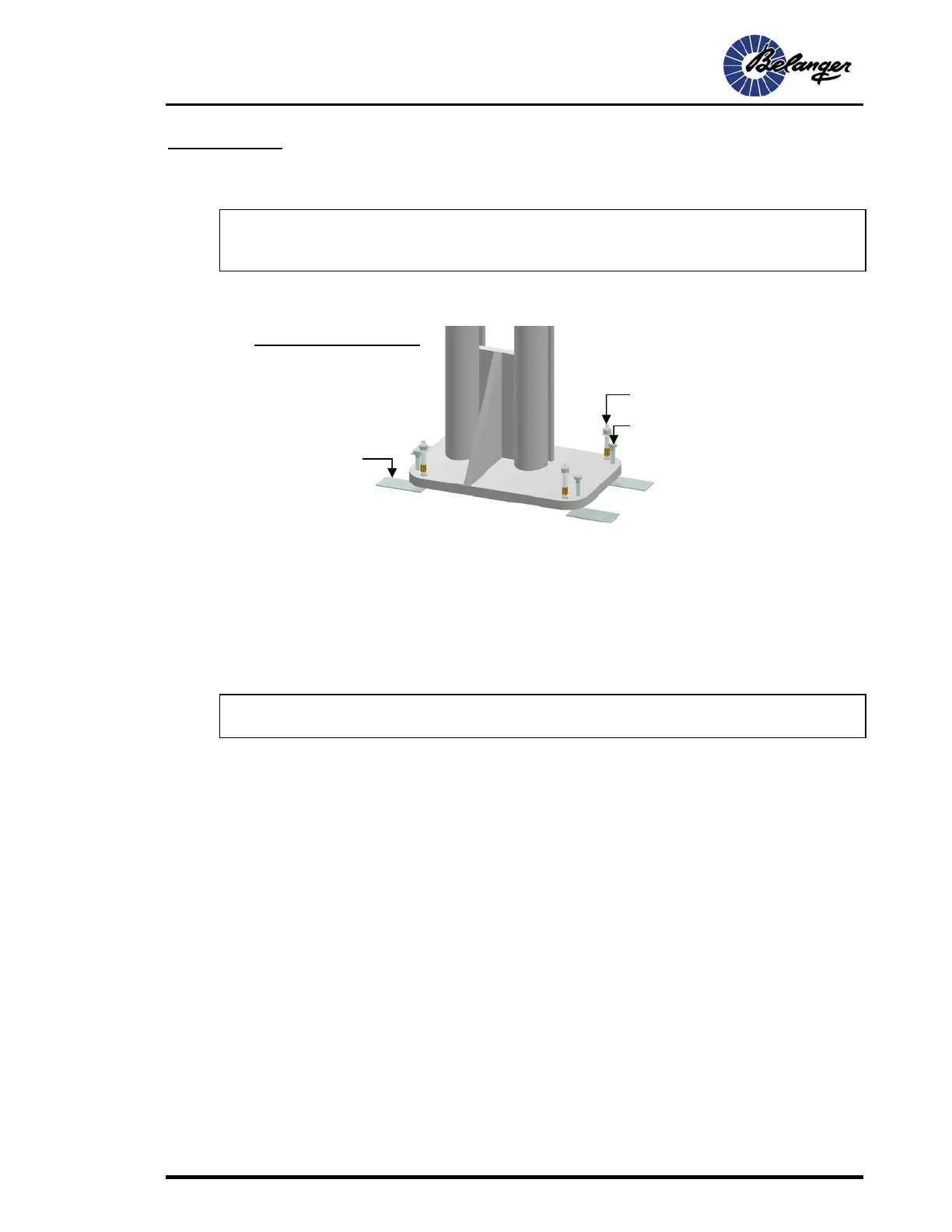

4) After making sure the stands are square to the conveyor, drill a 5/8” hole and place one 5/8”

lag bolt into place as shown below. Drill the other three holes.

5) Locate the supplied 3/4-10 x 3-1/2” bolts and place them into the threaded holes of the two

Base-Plates. These will be used later as the “leveling Bolts”. Place a small piece of steel or

aluminum plate under each leveling bolt so that it doesn’t penetrate the cement floor. Steel

or aluminum plating is field supplied.

6) Level stand both North, South, East and West

7) Now that the Stands are level, pound the lags all the way down.

8) Tighten the lag bolts.

Note: The stands will need to be leveled again after the Booms, Head Assemblies and Wash

Materials are installed.

Passenger Side Leg shown.

You can tell by the larger

plate surface being on the

side of the Boom and the

angle bracket facing outward.

La

Bolts

o in the outer

non-threaded

holes

Levelin

Bolts

o in the inner

threaded

holes

Metal plate to

stabilize leveling

process (typical)

Loading...

Loading...