33

ENGLISH

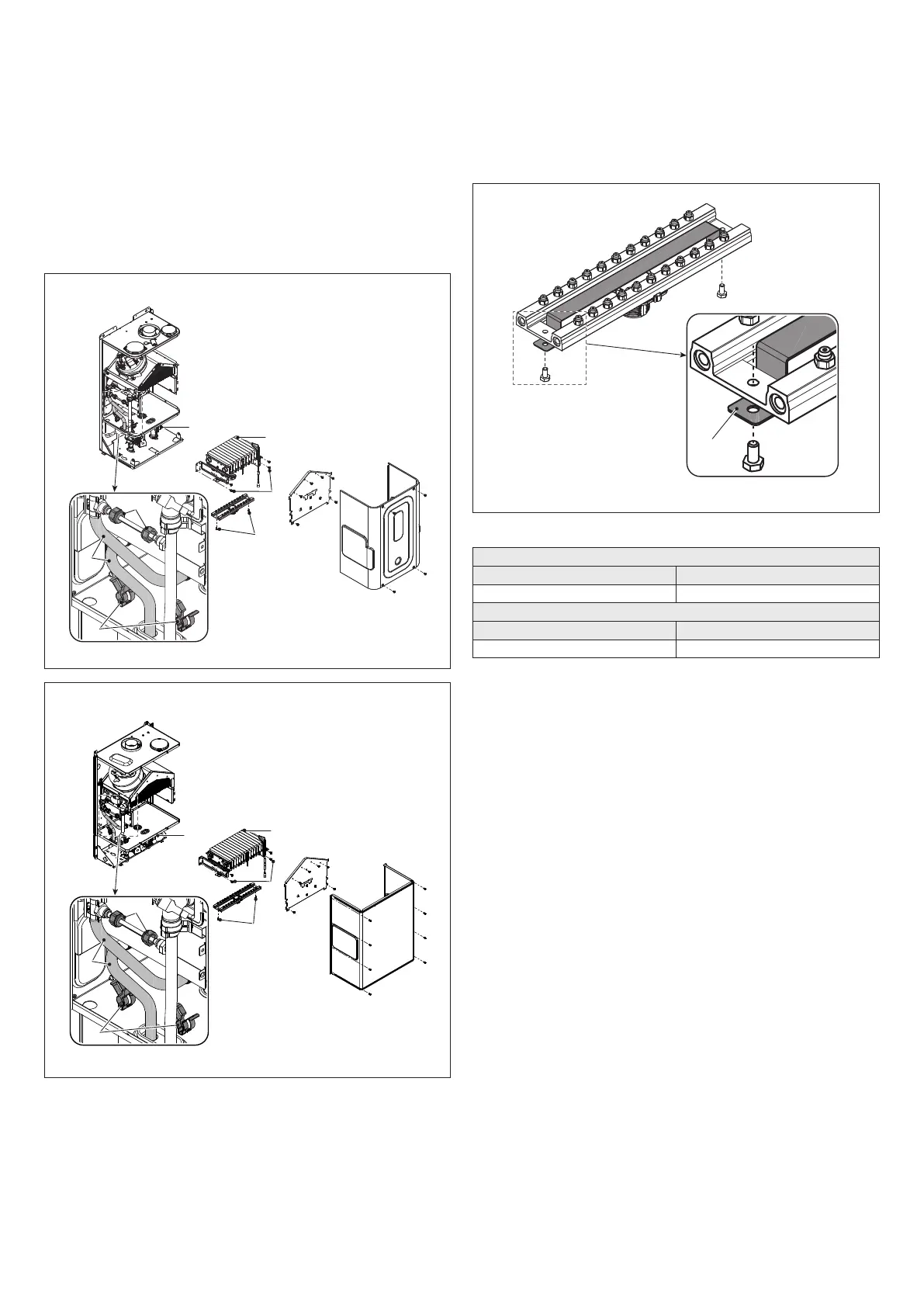

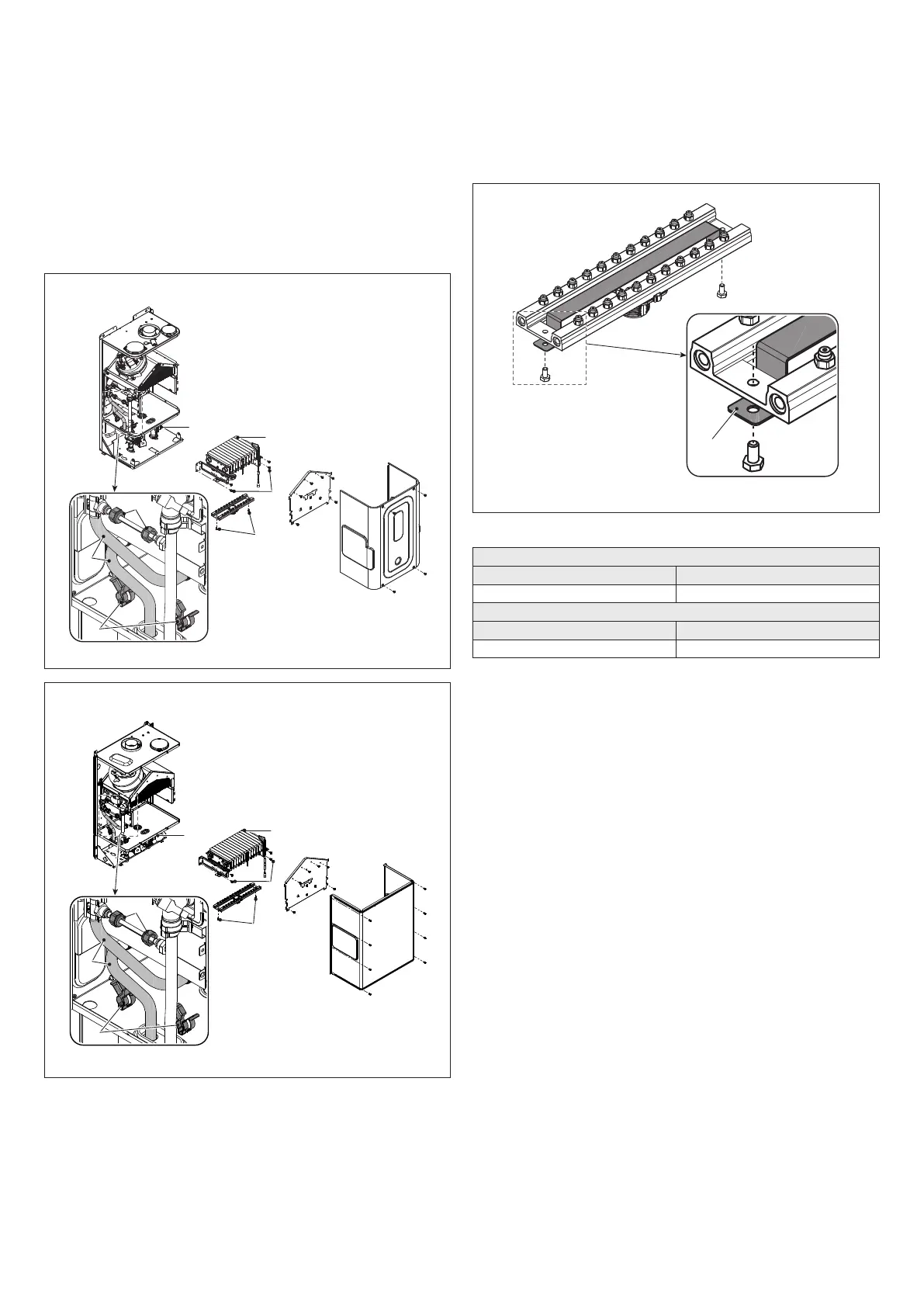

Proceed as follows to perform the conversion:

- switch off the electrical supply

- remove in succession the casing, the air distribution box cover and the

combustion chamber cover

- disconnect the glowplug cable connection

- remove the lower cable grommet from its seat on the air distribution box

- loosenthenuts(A)oftheby-passtrain

- loosenthenut(B)oftheburner/owmetertrain

- takeouttheclips(C)securingthetrainstotheburner

- disconnectthetrains(D)fromtheburner

- unscrewthe4screws(E)xingtheburnertothebackboard

- oncetheburnerhasbeentakenout(F),unscrewthescrews(G)xing

the manifold to the burner

- at this point, using a socket wrench and a fork spanner, remove the

nozzles and the washers and replace them with the ones in the kit.

Models 11-13

B

F

A

D

C

G

E

Fig. 20

Models 17

A

D

C

G

E

B

F

Fig. 21

b

Use and assemble the washers contained in the kit also in case of

manifolds without washers.

FortheconversionfrommethanegastoLPG,installtheburnerange

(H).

For the conversion from LPG to methane gas, remove it.

b

Beforeremovingtheburnerange,emptythewaterheaterasde-

scribed in the paragraph "Emptying the water heater".

H

Fig. 22

Then set

Parameter 4

(see paragraph "Parametersmenu")asfollows:

Conversion from METHANE to LPG

Parameter Value

4 1

Conversion from LPG to METHANE

Parameter Value

4 0

3.11 Adjustments

The boiler has already been factory set by the manufacturer.

Ifitisnecessarytoadjustitagain,forexampleafterextraordinarymain-

tenance, after replacement of gas valve or after gas conversion, carry out

the following procedure.

b

The maximum output adjustment must be carried out in the se-

quence

indicatedexclusivelybyqualiedpersonnel.

- Removethecasingbyunscrewingthexingscrews

A

(see section "

Removingthecasing").

- Loosenthescrewofthepressuretestpoint(1)downstreamfromthe

gas valve by roughly two turns, then connect the pressure gauge

- Disconnectthecompensationconnector(5)fromthegasvalve

Loading...

Loading...