BestCode Next Series 8 Technical Manual October 2022 Page 20 of 290

Process Time: 30-75 minutes (depending on ink viscosity)

A video guide is available here: https://youtu.be/2pgOsCyQHSA

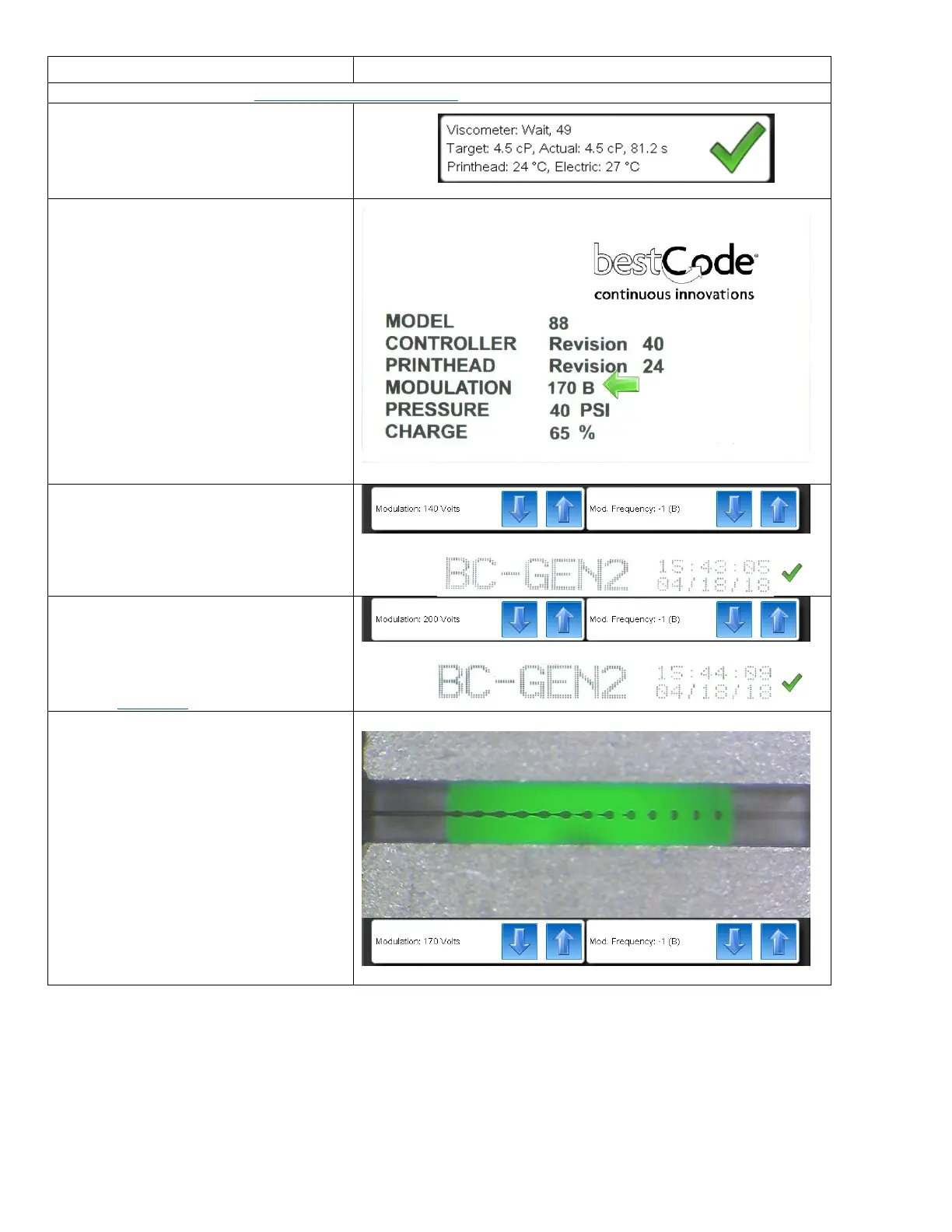

1. Run until the Viscosity is within range of

the Target Viscosity. (4.0-5.0cP).

2. Locate the Calibration label inside the

Air Service Entry Door.

Note: These values are generated by

testing the machine at 20C controlled

environment.

Different temperatures and ink types

will vary the modulation set point.

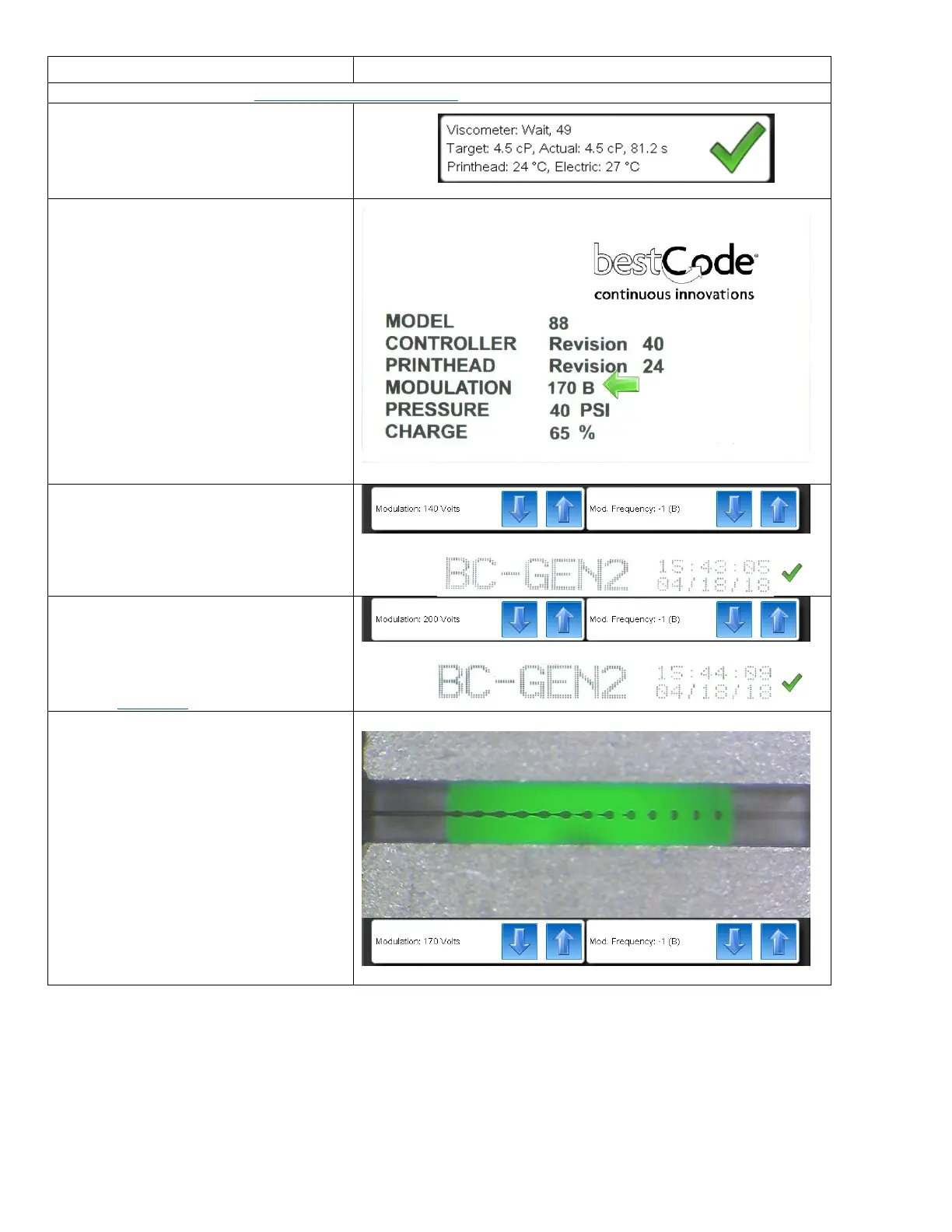

3. Decrease modulation to 30V below the

set point and test the print.

4. Increase the modulation to 30V above

the set point and test the print.

a. If the print is not acceptable,

perform a modulation calibration:

Guide Here

5. Return the Modulation to the set point

and inspect the drop breakup.

Loading...

Loading...