THE ENGINE

;1

•

Refitting

(16) Immerse the front main bearing cap moulded

rubber oil seal

in

oil

and

fit with the lip facing the

rear

of

the engine.

(17)

Fit

the rubber sealing ring

on

to the main oil

strainer pipe

and

fit new gaskets to the trans-

mission case.

(18) Lower the engine on to the transmission. Ensure

that the moulded rubber seal is correctly located

.•

Tighten the set screws

and

nuts as the transmission

__

is

being lowered in position.

MINI.

Issue

2.

16208

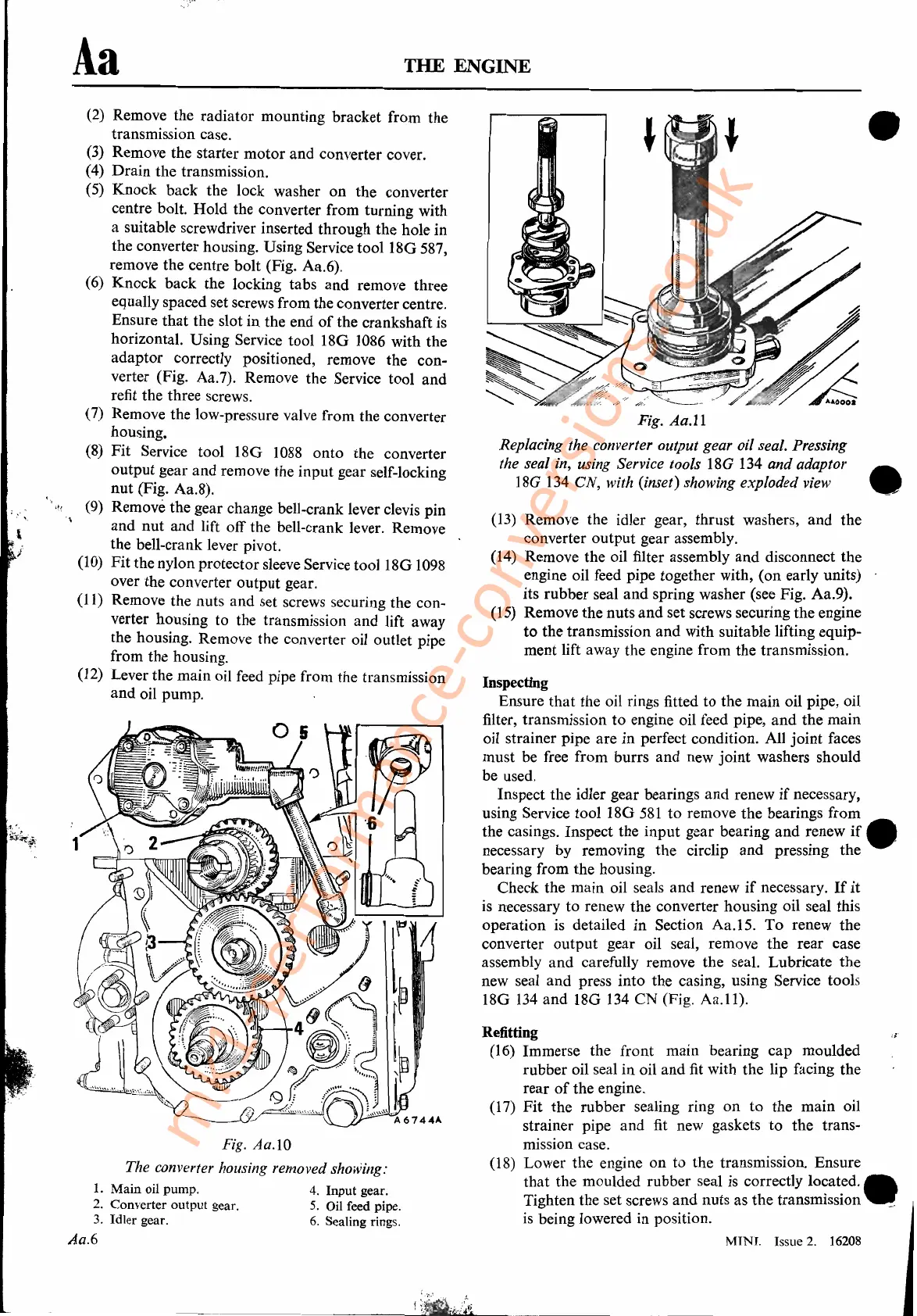

Fig.

Aa.ll

Replacing the converter output gear oil seal. Pressing

the seal in, using Service tools

18G

134

and adaptor •

18G

134

eN, with (inset) showing exploded view

(13)

Remove the idler gear, thrust washers,

and

the

converter output gear assembly.

(14) Remove the oil filter assembly

and

disconnect the

engine oil feed pipe together with, (on early units)

its rubber seal and spring washer (see Fig. Aa.9).

(15) Remove the nuts

and

set screws securing the engine

to

the transmission and with suitable lifting equip-

ment lift away the engine from the transmission.

Inspecting

Ensure that the oil rings fitted to the main oil pipe, oil

filter, transmission to engine oil feed pipe,

and

the main

oil strainer pipe are

in

perfect condition. All

joint

faces

must be free from burrs and new

joint

washers should

be used.

Inspect the idler gear bearings

and

renew

if

necessary,

using Service tool 18G

581

to

remove the bearings from

the casings. Inspect the input gear bearing and renew

if.

necessary by removing the circ1ip and pressing the

bearing from the housing.

Check the main oil seals and renew

if

necessary.

If

it

is

necessary to renew the converter housing oil seal this

operation is detailed in Section Aa.15.

To

renew the

converter output gear oil seal, remove the rear case

assembly and carefully remove the seal. Lubricate the

new seal and press into the casing, using Service tools

18G

134

and

18G

134

CN

(Fig.

Aa.1l).

Aa

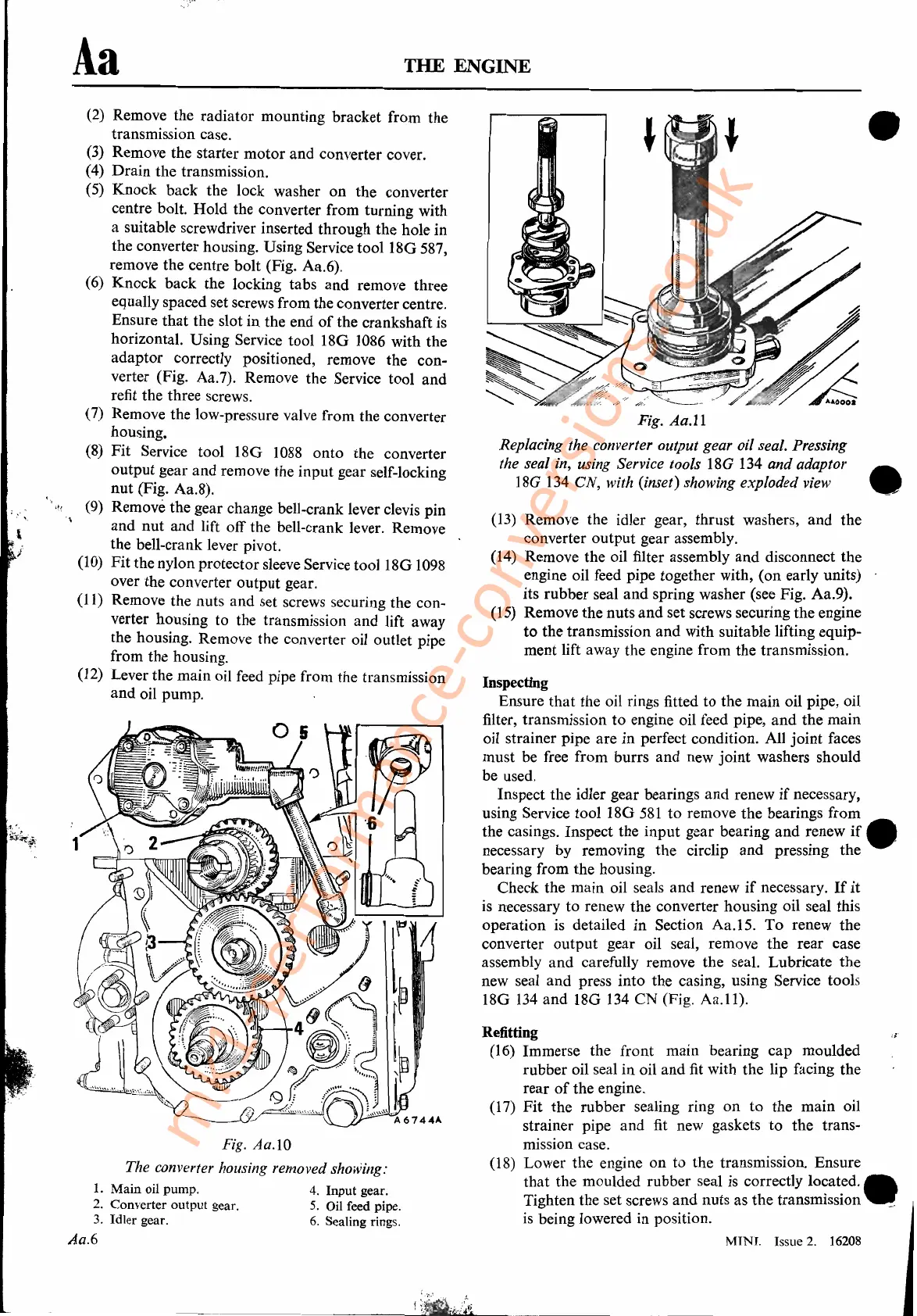

Fig. Aa.IO

The converter housing removed showing:

1.

Main

oil pump.

4.

Input

gear.

2.

Converter

output

gear.

5.

Oil feed pipe.

3.

Idler

gear.

6.

Sealing rings.

Aa.6

(2)

Remove the radiator mounting bracket from the

transmission case.

(3) Remove the starter motor and converter cover.

(4) Drain the transmission.

(5) Knock back the lock washer

on

the converter

centre bolt. Hold the converter from turning with

a suitable screwdriver inserted through the hole in

the converter housing. Using Service

tool18G

587,

remove the centre bolt (Fig. Aa.6).

(6) Knock back the locking tabs

and

remove three

equally spaced set screws from the converter centre.

Ensure

that

the slot

in

the end

of

the crankshaft is

horizontal. Using Service tool 18G

1086

with the

adaptor correctly positioned, remove the con-

verter (Fig. Aa.7). Remove the Service tool and

refit the three screws.

(7) Remove the low-pressure valve from the converter

housing.

(8)

Fit

Service tool

l8G

1088

onto the converter

output gear and remove the input gear self-locking

nut (Fig. Aa.8).

"~

(9) Remove the gear change bell-crank lever

c1evis

pin

and

nut

and lift off the bell-crank lever. Remove

the bell-crank lever pivot.

(10)

Fit

the nylon protector sleeve Service tool 18G

1098

over the converter output gear.

(11) Remove the nuts and set screws securing the con-

verter housing to the transmission and lift away

the housing. Remove the converter oil outlet pipe

from the housing.

(12) Lever the main oil feed pipe from the transmission

and

oil pump.

mk1-performance-conversions.co.uk

Loading...

Loading...