-48-

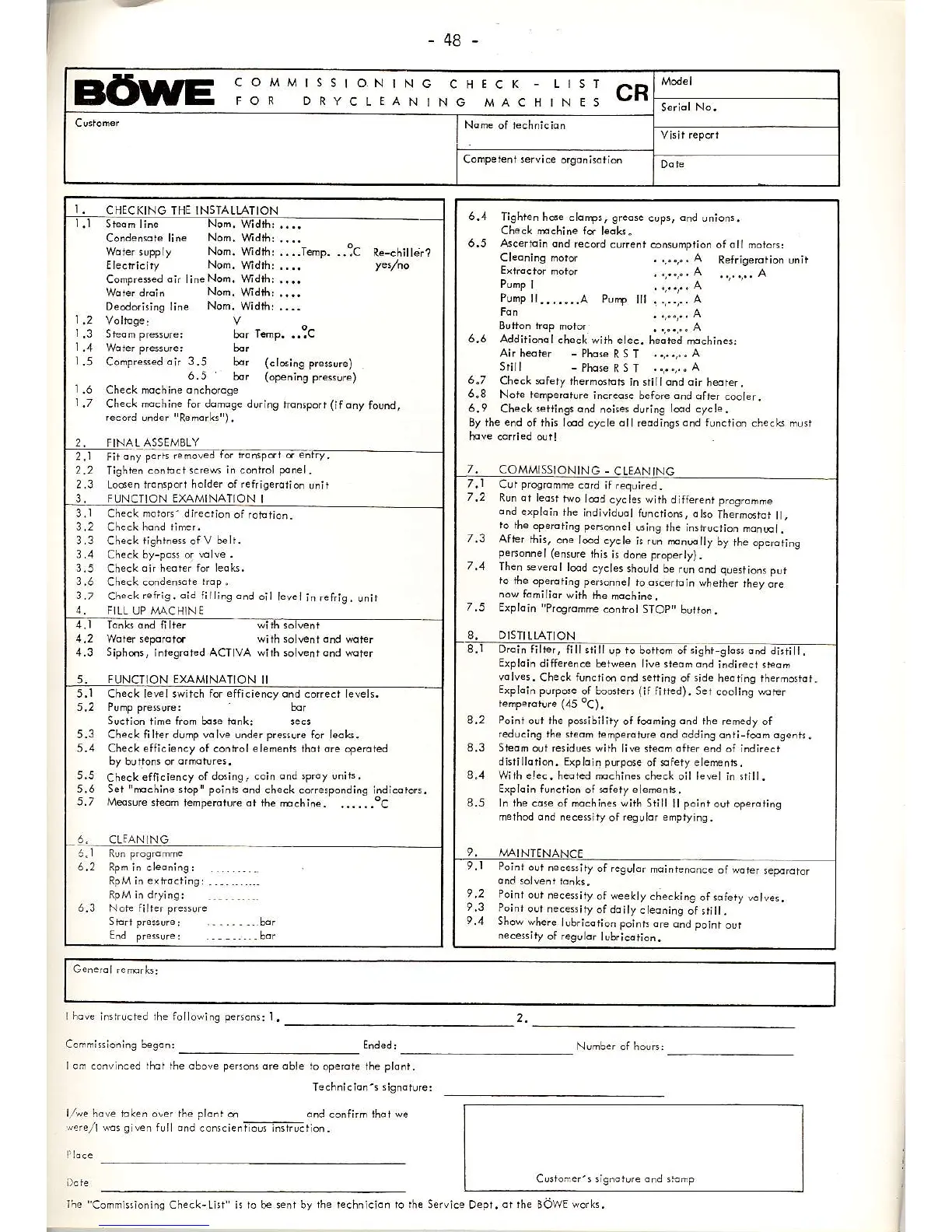

COMMISSIONING

CHECK

-

LIST

FOR DRYCLE,ANING

MACHINES

CR

Compebnr eervie

orgonkotion

I.

CHFCKING THE INSTALLATION

l.l

Steon line

Nom.

Widlhi....

Condensote line

Non.

Widilr:

....

Woi€rrupply

Nom.Wdin:....T6p...:C

Re-chjtler?

Electi.iry

Non.

Wdrh:

....

y.tho

Compr€$ed

on

lineNon.

\Md*,:

....

Woler drcin

Non.

Wdrh:....

Decndising line

N.m.

Widlhr

....

1.2

V.ll!se:

V

^

L4

Woter pre$ure: bor

1.5

Cohpreßed.t

3.5

hor

Gl6ins

pre$ure)

6.5

bor

(openins

p.e$!re)

I

.6

Check mchine on.horös€

I.7

Check dchine lö. donoge dlrins

Fioispöri

(ifdny

rouno,

reco'd

under

'Reh.rk3'

).

2.

FINAL

ASSEMSLY

2. f-

tp;

"m..%

6-i-;d:

d-'1-.-

2.2

Tighren

conbct sieH

in cöntrol

Ponel.

2,3 Lo6en trcnlporr holder of

r.tigedtion

uiii

3. FLJNCTION EXAMINATION

I

3.1 Check moroß' !nedion

of röirtion.

3.2

Check

hand rimer.

3.3 Check rishhe$ öfV

b€li.

3,4 Che.k 6y-po$ or wl"e.

3.5

Chech

oi' leoier rd leok,

3.6

Check condensdie

hcp

"

3.7

Cheqk

rcfrig. oid fi I

ins

ond

öil

l€vel

tn.ef.ig.

unir

4.

F]LL UP A4AC

H!N

E

4.1 ldn]<l dnd fil,er riA solve.i

4.2 warer seporord wilh sol€ir dnd

Mter

4.3 5iphq3, inregdr€d acTlva wirh solv€drdnd wr€r

5.

FUNCTION EXAMINATION

II

I

C\-crtcF ,^ircSfo

",.i.ien.y

o.d cdre.r e.st,.

2 Pump presur€: b.r

suction

tine lrom boee r.nk:

3 Check filter dump vdlve under presure lor e.k.

4 Check effi.iency

ot co.hol

elemenh

ihot ore cperored

by butrons d

ormlu.ei.

5

Check

eflicie.cy

of ddins, .oii

cnd

+dy

units.

6 Sel

"mchine

$op" poinr3 dnd

ch€ck conespondins

jnd,cordr.

7 Merure

3t€on lnp€rcrure or

rhe mchine.

......oC

CLFAN]NG

'.1*-

2 Rpm

in cleaningl

RpM in

etrrocting:

_

RpM in drying:

Sli pre*urc:

....-- bdr

End

presure: b(

5,

5.

5.

5,

5,

5,

5.

9r.

6.4

Tishten hc€ clonps,

sreose

.ups,

ond

unionr.

Check dchine

ld leak"

6.5,a6cerroin ond

record cuiienr.onsunprion

olotl m.roß:

Cleoning mord

.

1"r""

A

Retris€Erion

unii

Punp

I

..,..,..

A

Pump

|t.......A

Punp

ttl

..,..,..,A

Fon

..,..,..

A

Sutton toP

hotor

.

.,.., A

6.6

Addnionol.heck

wilh elec.

heobd ndchiner:

Anheatr

-Ph.sRST

..,..i..4

sri,l

-PhosRST

..,.",.,4

6.7

Check

slety

$ermdrois

'n srilldnd on

h€dre..

6.8

N6te r€mp€rctore

inc.eose belore ond

olbr

.oole

6.9

Ch€ck

erlinssdnd

noises durins

l@d cycle.

By ihe €nd

ol this ldd cycl€ oll reddins:.nd

runction

che.b mu$

hove dried &il

7.

COMMISSIONING

-

CLEANIN

7.1

Cur

pros.dmre

clrd ilrequired

7.2

Run or le.r

rwo tdd

cycte! wiih differeni

progrohh€

dnd

exproin rhe

indivjdudt

functions, ct.o

Ihern6r.r

[,

ro

fi"

ooe_or:nq p--anel

6i

qtrei-.hucti.n--

w.

7.1

Afpr

+ir, öne

da c,ct-

k

,u-

mnF't\

bv

.h-

-, <,a,,r9

peßonner

(ensuE

ihi3

is done

Froperty).

7.1

The-'e.ercl

l@o.,-t-eiho.td

o-.unor

ql"s.ior\pul

'o

te op-E,irg

p.,5o1i€J

ro dn-J

o n

-l

-hej

*-y

o.e

nöw rodiiior

wi$ Ae

mchine.

7.5

Exploin

lProgronre.onhöt

STOP'

bu on.

8. DISTILLATION

8.1 D6in filt€r,

fillrillup

ro b6 oh "f igir-sl(rfu.d

di3ri t.

Erploin

!ifi€r€^c6

berween live 3teom ond

indir€cßreoh

volves.

Ch€ck funclih oid seiiins

of

side

hediing rheri6idr.

Expldin

pulpd€

6f bo6E*

iir

fiiEd). 5er

cooiing rcrer

renD€rdrure

(45

"c).

8.2

Poinl

out the

p.*iSiliiy

offdnihg

ohd

rhe renedy of

.educing th€ $edm

rempedlur€ ond odding onti-fdh ogenrs.

8.3 Sleofr

our r€iidues wiih

li€ lteom

crrer end

of indnect

dkrillotion. Expldin purpde

of sfery etemnh.

3.4

wi

h e

-c.

h€ted mchi^e'

<Le(l oil

l"Fl

n s,i

Exploin fundion

ot

sfely elemenE.

3.5

In the cd5e of mochines wiih Siill

ll

poini

our opedrins

method ond neces y

ofreeul.r

empryins.

9.1 Poinr

öur

nec€sily

of rcgulor

mdinre^dnce

.t wcte.

sepdroior

ond sotvent

ronkr,

9,2

ooin'

our

-e.e.,i-r

ot

,eett/

<n--.ins

of sote-, .dr.e,.

e.3

Poinr

out ne.esiry

of doily

.teoninq

of rr

.

e.4

Show wher€

tu&;.arion p;i.r,.o

oia

p.i"r

.*

hece*hy

of 'esuldr

tubricolion.

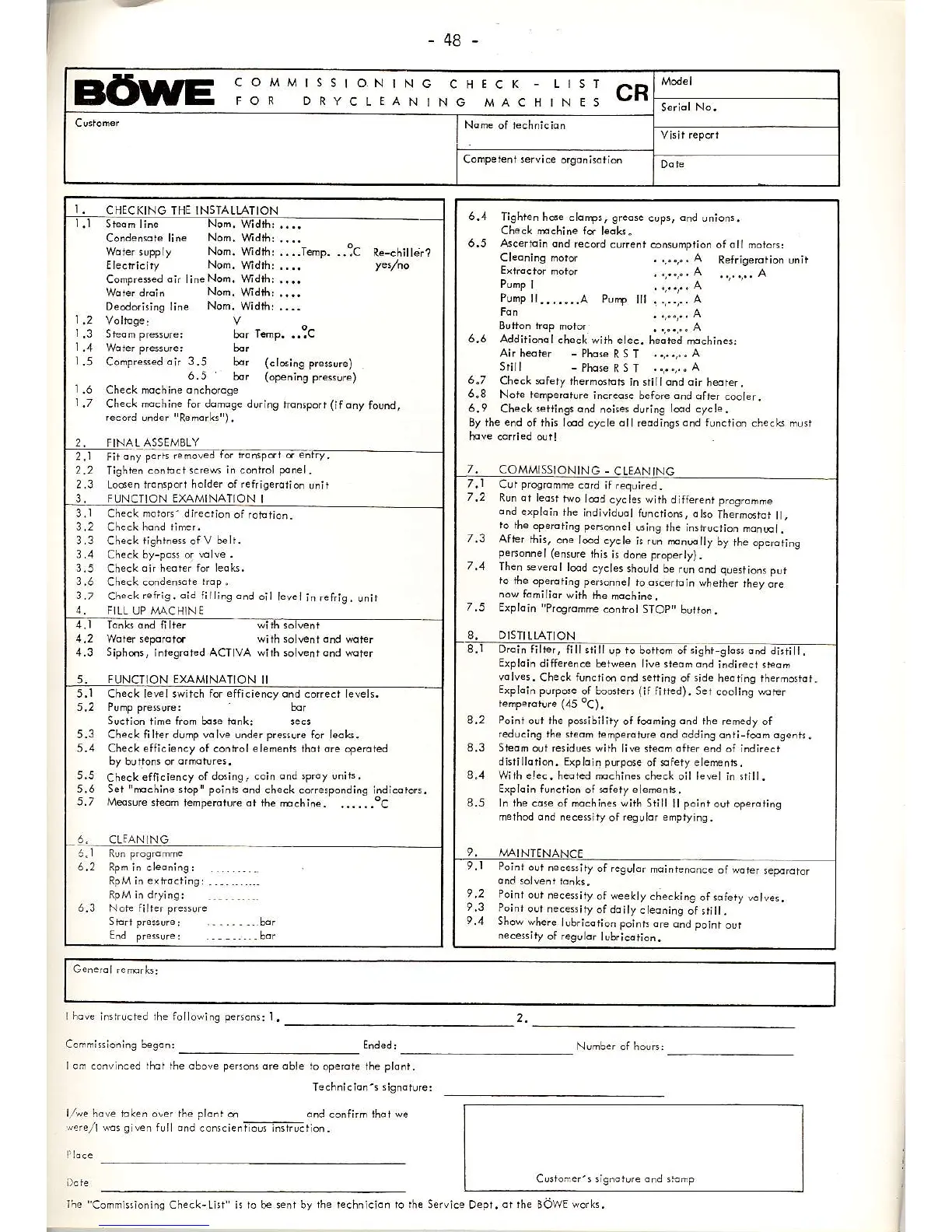

I h.ve

in*ru.red rhe fol owing

peß.ns:

l.

2,

I on .ö.'ii.ed rhoi ihe o6ove peßöd

dre

able

ro op€rcie rhe plcnr.

Technici.n-5

sisndture:

l,/.a hove irken o"r ihe plonr

q

ond confnm rhoi we

.-e,el

wds

eiven

rult dnd

conicien;i;;in*-;rioh.

au5ro-er's sigiorure ond

.5mp

Ihe

"Commi55iönins

Che.k-Li5i ir to be sent by

ihe rechnicidn

ro

rhe Ser!i.e

0ept.

öi 'he

BOwE

works,

Loading...

Loading...