BRP-Rotax

MAINTENANCE MANUAL LINE

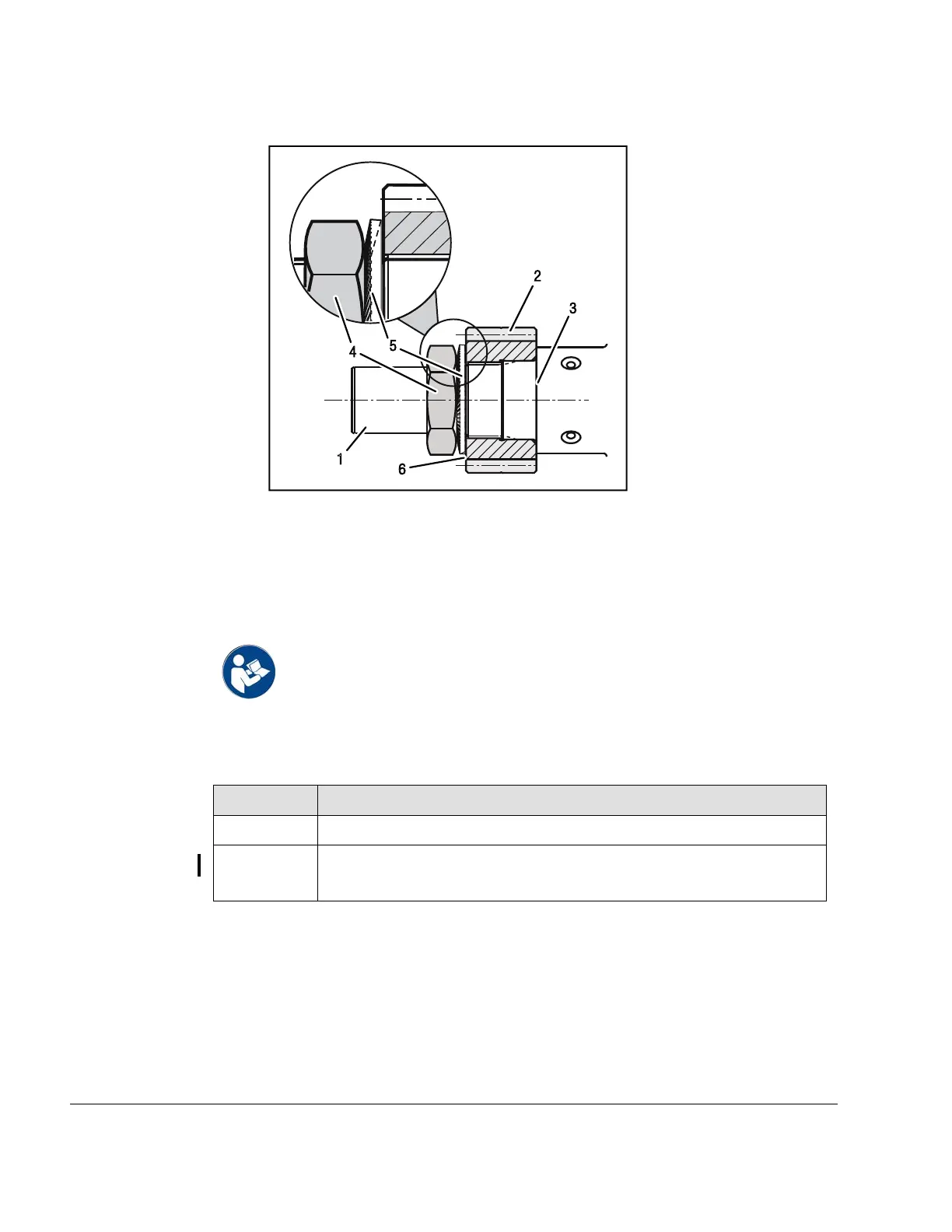

Figure 5.7

1

Crankshaft (power take off side)

2

Drive gear

3 Crankshaft 4 Hex. nut

5 Friction washer VS-30 6 Serial number

See Maintenance Manual Heavy for the engine type Chapter 72-10-00

section Wear limits (CS24).

NOTE

If there is slight vertical run-out, replace the nut and repeat the measurement.

Step

Procedure

5

Insert 2 dowel pins 6x20 into the crankcase.

6

Apply engine assembly grease into the needle bearing and lubricate the

crankshaft with LOCTITE Anti Seize.

NOTE

Engines of the 912 Series configuration 2 have an oil seal.

•

Grease oil seal for propeller shaft in crankcase.

• Lubricate bearing bore for propeller shaft.

• Keep the rollers of the roller bearing in position with grease to facilitate assembly of pro-

peller shaft.

05–50–00

Page 8

January 01 2020

Effectivity: 912 Series

Rev. 0

Loading...

Loading...