SnackFix 2016-08 99

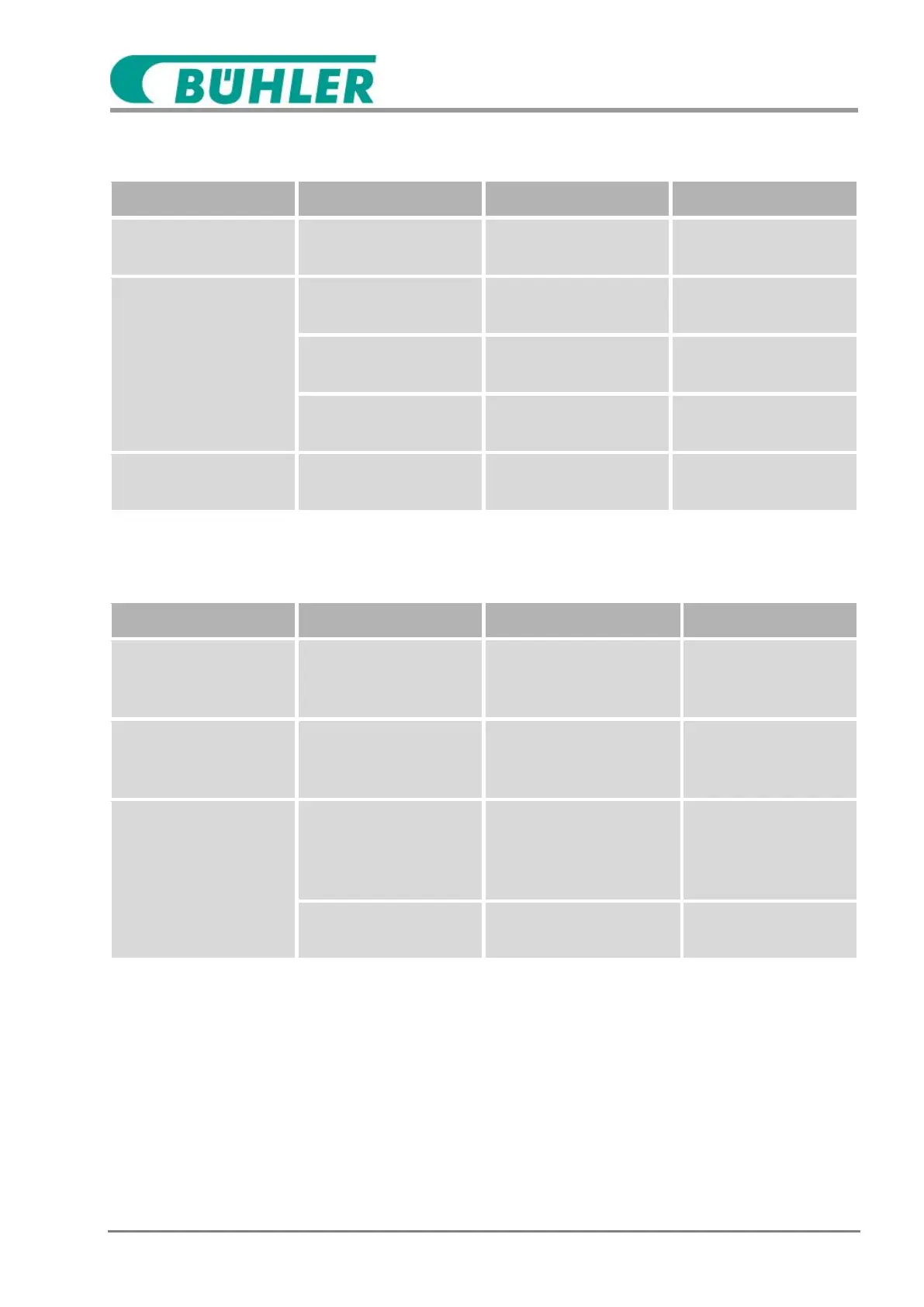

Conveyor belt is too

slow.

Conveyor belt runs late-

rally.

Conveyor belt resp.

rollers are dirty.

Clean belt resp. rollers.

Conveyor belt is ten-

sioned irregular.

Adjust belt tensioning

roller.

Guide roller is adjusted

at an angle.

Conveyor belt and roll-

ers are heavily dirty.

Scraper is adjusted

incorrect.

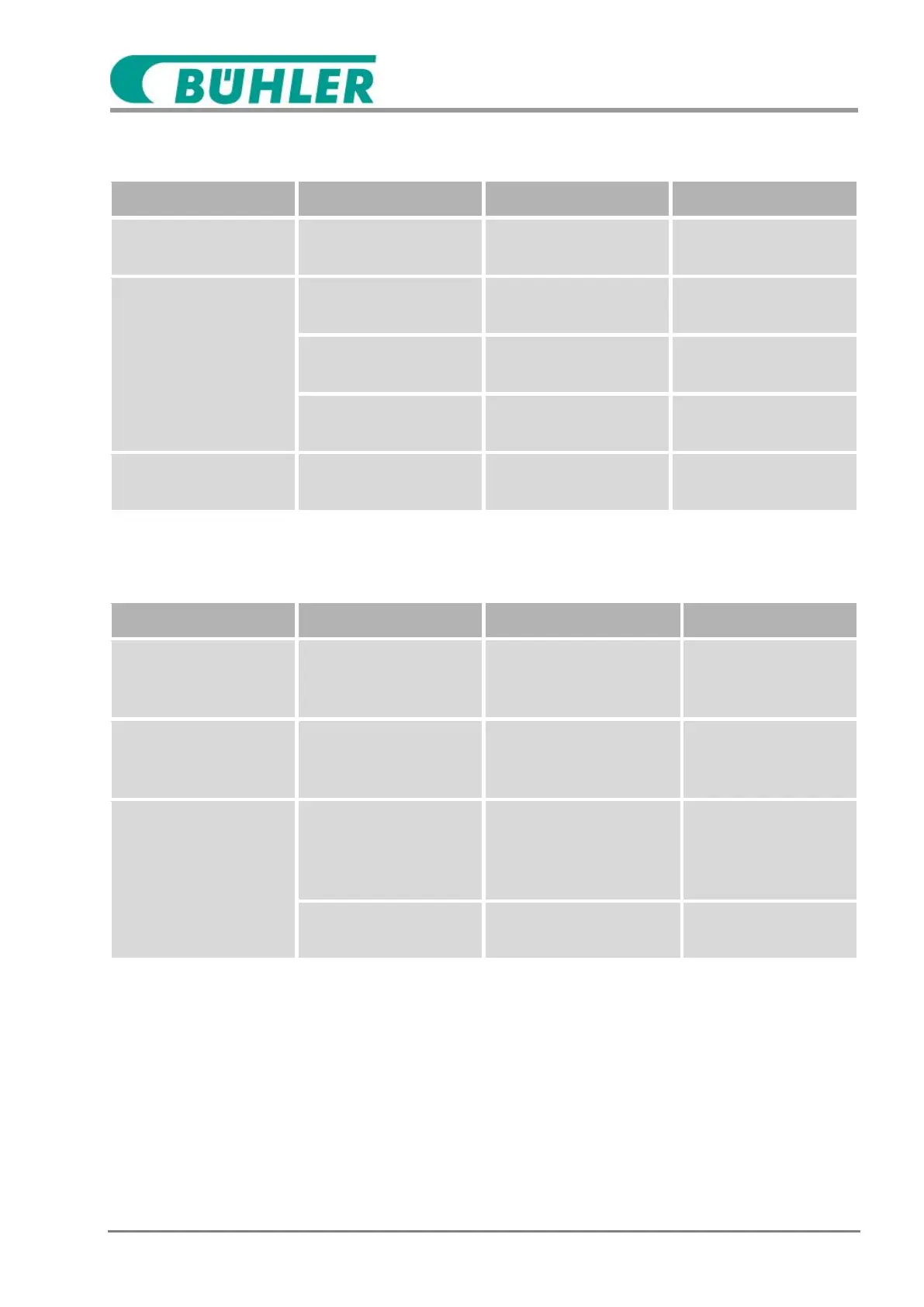

10.5.2 Equalizing roller EGW 180-100

Mass slab is not suffi-

ciently pressed together.

Distance of equalizing

roll to the mass slab is

too big.

Adjust the height of the

equalizing roll

Mass slab is too much

pressed together

Distance of equalizing

roll to the mass slab is

too small.

Adjust the height of the

equalizing roll

Supply of insulating

liquid is not sufficient

(optional supplementary

equipment)

Increase the supply of

insulating liquid.

Distance of scraper to

equalizing roll is too big.

Measures after Malfunction Removal

Perform the following steps after having removed the malfunction:

Reset the emergency stop devices.

Acknowledge malfunction.

Ensure that there is nobody within the hazard zone.

Loading...

Loading...