74 SnackFix 2016-08

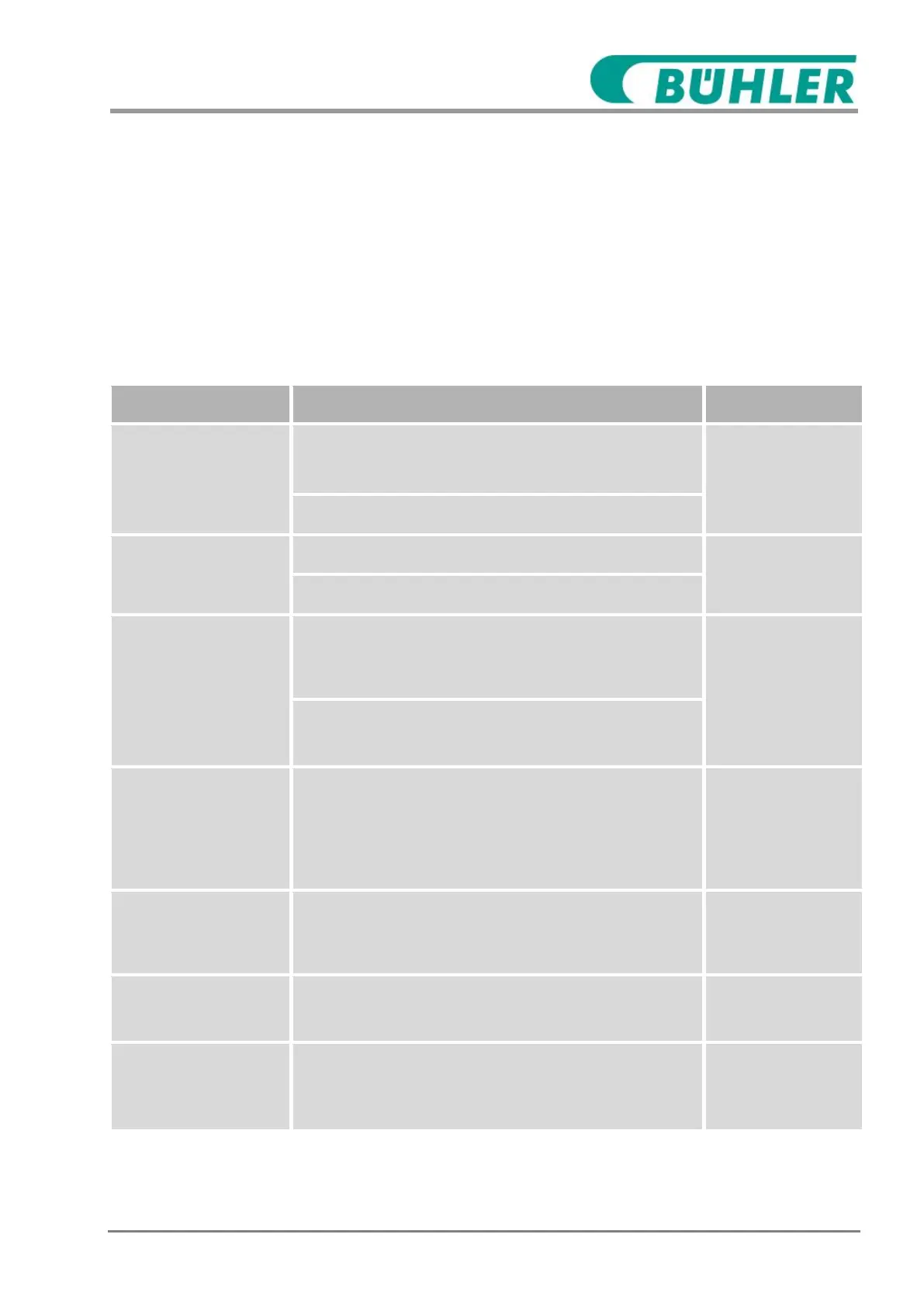

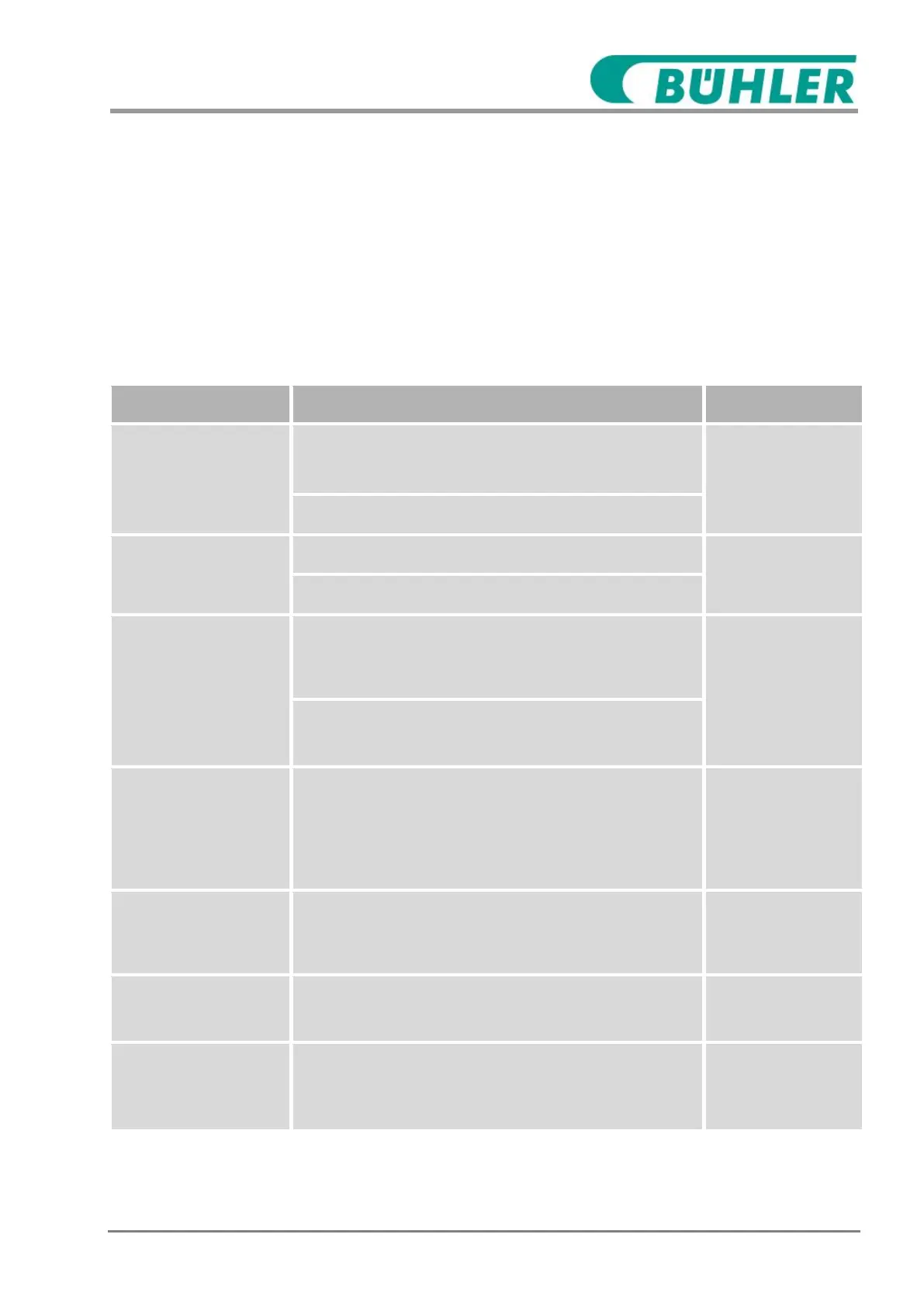

8.2 Maintenance Plan

The following sections describe the maintenance works that are re-

quired for an optimum and failure-free machine operation.

The maintenance intervals must be shortened accordingly in case you

find increased wear during the regular controls. Contact the manufac-

turer if you have any questions concerning maintenance works and

intervals. Please see page 2 for the service address.

Check the drives:

Temperature, wear and noises

Check hoses for damages and leaks

Perform a visual check for damages and leaks

Visual control scrapers:

Wear, corrosion, adjustment and function, eventually re-

adjustment

Check cutting device:

Knife, scraper, downholder

Maintenance unit:

Check compressed air.

Drain the water separator (at a condensate level of ap-

prox. 10 mm (0.39 ") below the filter element).

Check control panel:

Have the control panel checked for damages by an elec-

trician

Check drives:

Visual control of oil level, temperature, wear, noise

Safety valves:

Perform a visual check for damages and leaks. Check

existing seals.

Loading...

Loading...