63

Firestat Test Procedure

NOTE: The following should be tested with battery power only (A/C power disconnected) and then tested

with A/C power connected.

ATTENTION: You do not need nitrogen for this test.

CAUTION!: The use of a torch or flame is strictly prohibited.

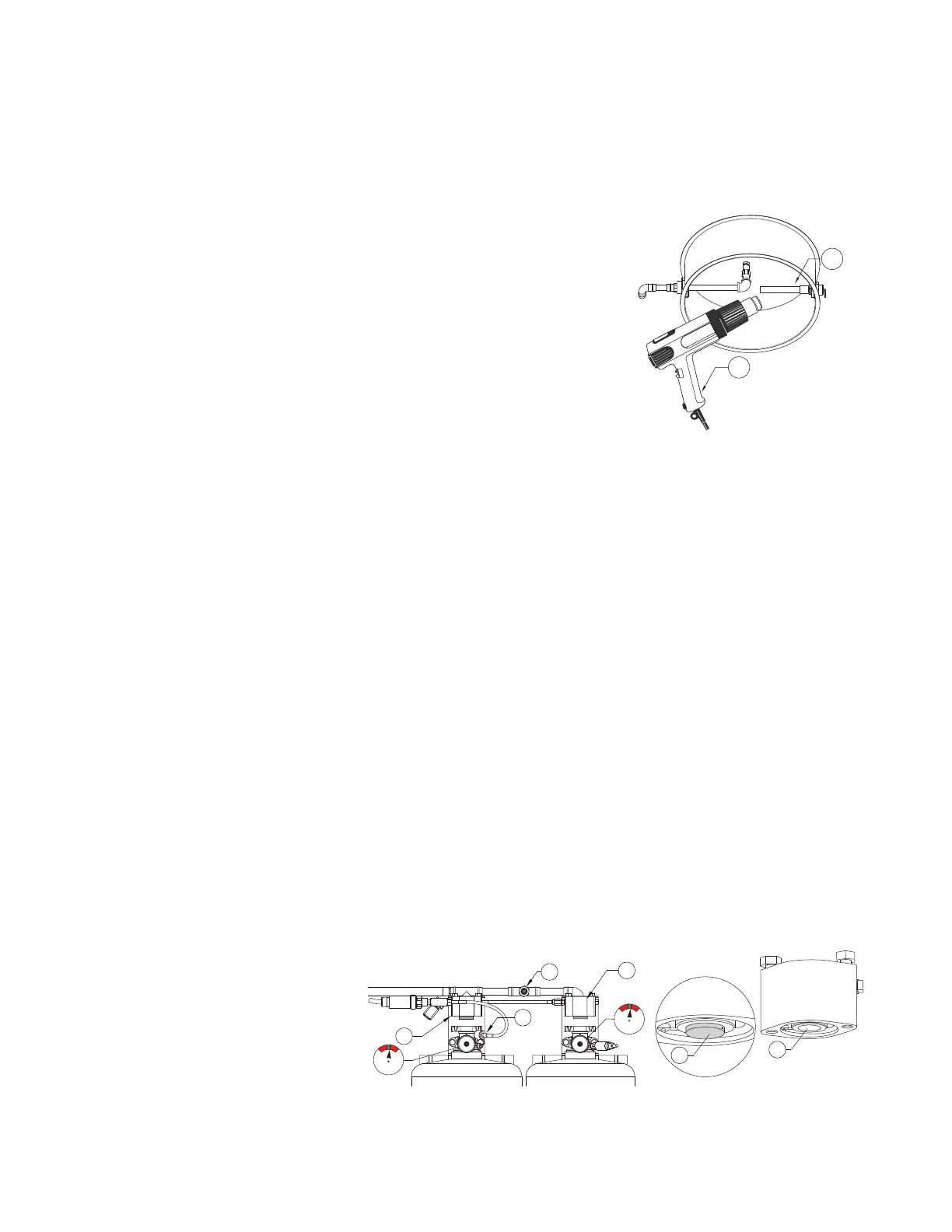

Figure 56 - Firestat Riser Location

• Use a portable heat source to apply heat to the duct Firestat in accor-

dance with the manufacturer’s instructions. Please refer to applicable

detector manufacturer’s manual. Refer to Figure 56.

• When the Firestat’s heat set point is reached, the fire system will acti-

vate. Some residual nitrogen from the test cylinder may release.

- When performing this test with battery power only, check the CORE-

board fire status light.

- When performing this test with A/C power, the exhaust fan will acti-

vate. Depending on the hood lights activation setting, they will turn

on or off.

• Check all Firestats in the system.

• After the system is tested, install nozzle caps, and install hood filters.

Disconnecting Service Cylinder Tank

• Place the TANK fire system into “Test” mode.

• Relieve pressure from the Nitrogen Cylinder.

• Cylinder assemblies with one Schrader valve:

- Slowly disconnect the inline filter from the PAK hose.

• Cylinder assemblies with dual Schrader valves:

- Check all cylinder gauges to confirm proper pressure is within the “green” range. If pressure is low, refer

to “Adding Nitrogen to Tank(s)” on page 68.

- Slowly disconnect the test hose with inline filter from the tank cylinder.

• Relieve pressure in the actuation line. Slowly disconnect the test hose from the PAK service valve.

• Disconnect the test hose from the fire system distribution piping service port. Remove low-loss fitting adapter.

Re-arming System

• Reset each PAK and any SVAs by pushing the spring-loaded pin on the piston. Press the piston into the body

of the actuator.

• Verify residual pressure is relieved at Schrader valve.

NOTE: If a PAK/SVA fails to operate or cannot be properly reset, the unit must be replaced. Refer to

page 67 for replacement procedures.

• Verify all of the actuation lines between the PAK and SVA(s) are secure and tight. Place Schrader valve cap on

the fire system distribution piping service port.

• Check all cylinder gauges to confirm proper pressure is within the “green” range. If pressure is low, add nitro-

gen. Refer to “Adding Nitrogen to Tank(s)” on page 68.

• Re-arm the control panel by placing the package in “Armed” mode.

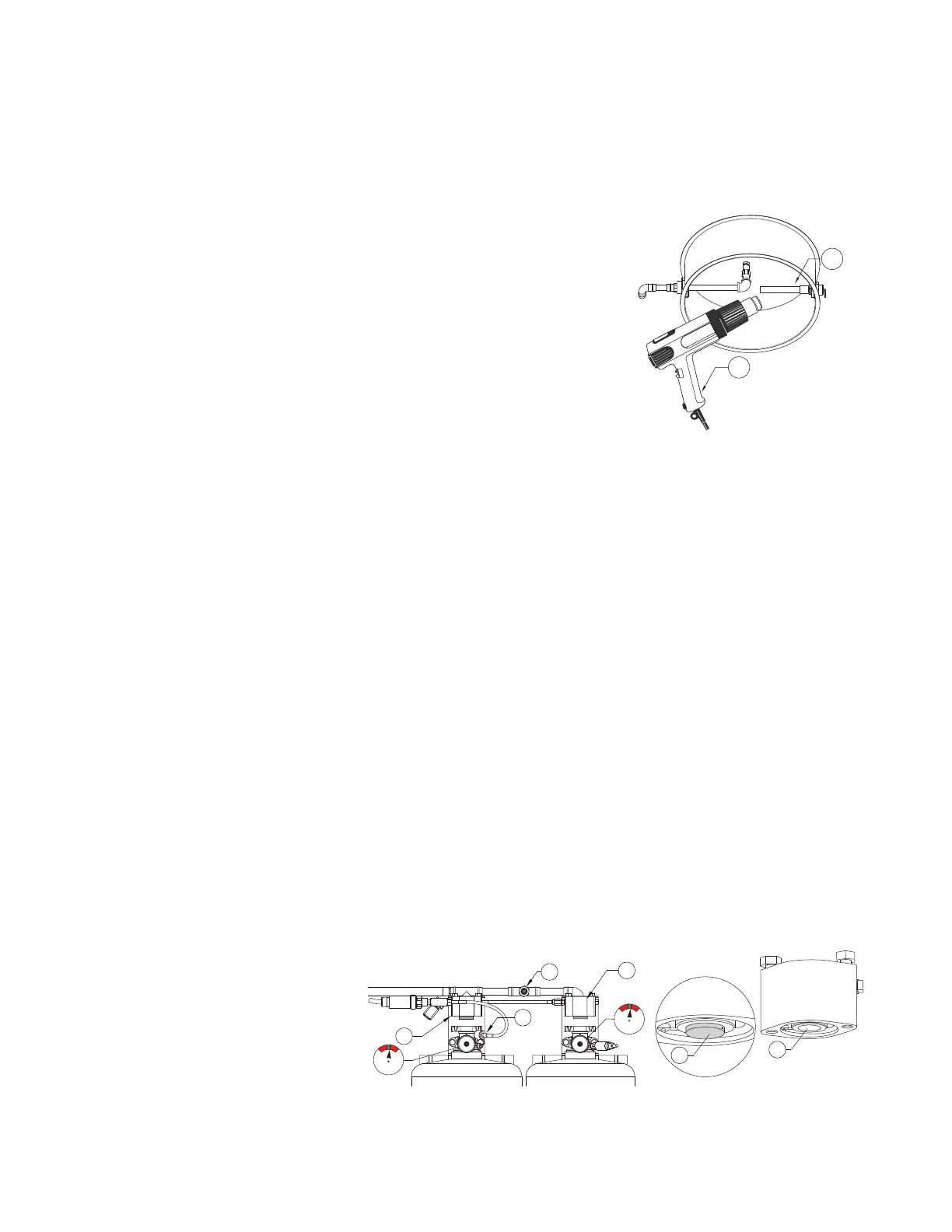

Figure 57 - Resetting PAK/SVA(s)

1. PAK in Ship/Test Position

2. SVA in Ship/Test Position

3. Distribution Piping Service Schrader

Valve

4. Primary Actuator Hose

5. Actuator Activated

6. Actuator Set Position

NOTE: Tanks should never be filled

with agent in the field.

Loading...

Loading...