42

Maintenance of the Liberty Blue

Maintenance of the Liberty Blue

Recommended Routine Maintenance Schedule

A routine maintenance protocol is vital for the long-term operation of the Liberty Blue.

Daily Maintenance

• Ensure the ber optic probe is fully inserted into the thermowell of the reaction vessel.

• Empty waste reservoir and ll main wash position.

Biweekly Maintenance

• Backush all positions except Main Wash (see Backush Reagent Positions & Backush Deprotection).

• Replace amino acid, activator, and activator base solutions.

Monthly Maintenance

• Perform a timed addition calibration for all timed additions (see Timed Addition Calibration).

• Verify the performance of the ltered drain (see Reaction Vessel Drain Test).

• Review recent run history reports to ensure that the Liberty Blue is heating properly.

Semiannual Maintenance

• Replace all amino acid diptube lters.

• Replace the Main Solvent and Deprotection lters.

• Replace the reaction vessel (or as needed by software Maintenance Tracker).

• Verify performance of waste sensor (see Verication of Waste Sensor Operation).

Annual Maintenance

• Replace all amino acid and reagent manifold o-rings. If the HT resin loader option is included, replace these

manifold o-rings also.

• Tighten the diptube nuts in the manifold ports for each reagent position. If the HT resin loader option is

included, tighten these diptube nuts also.

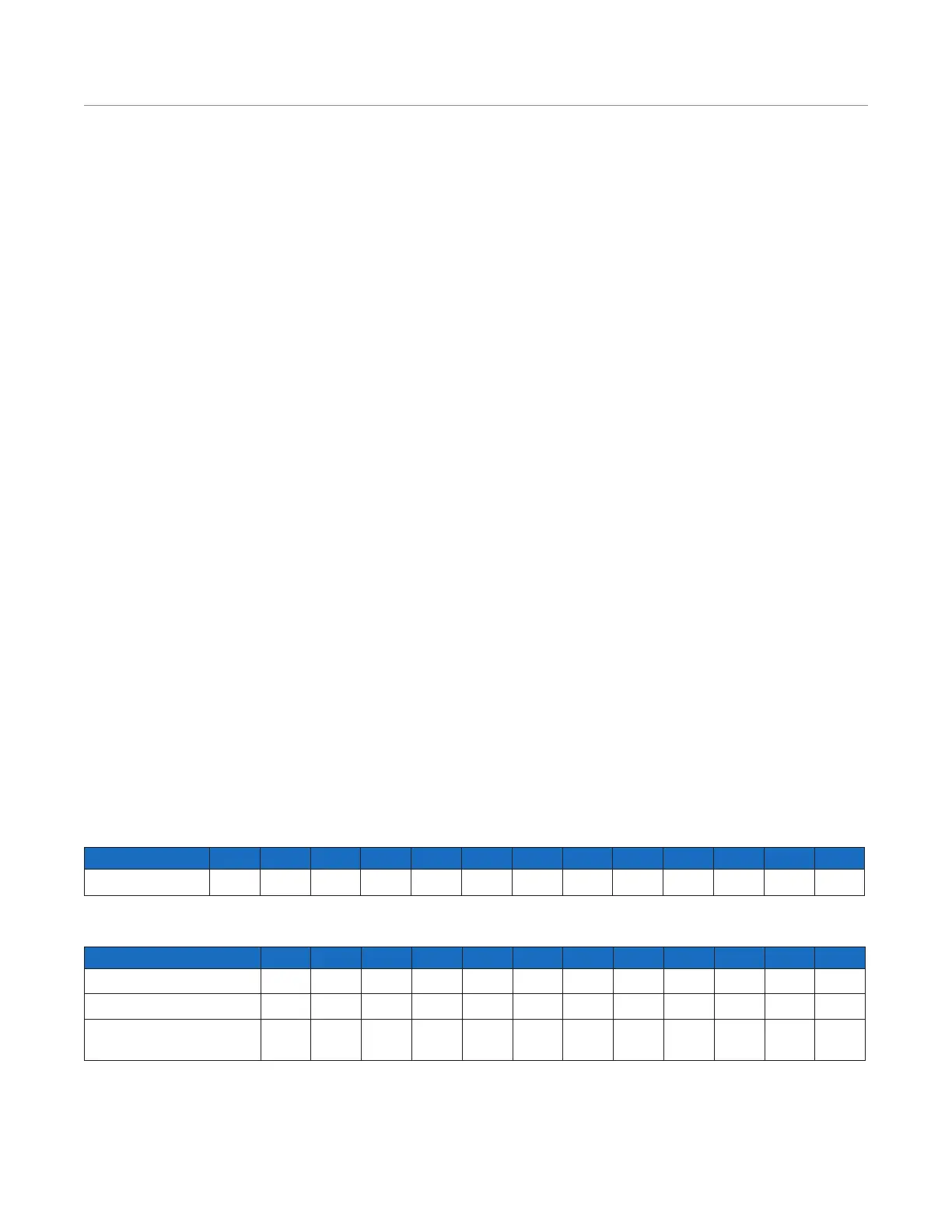

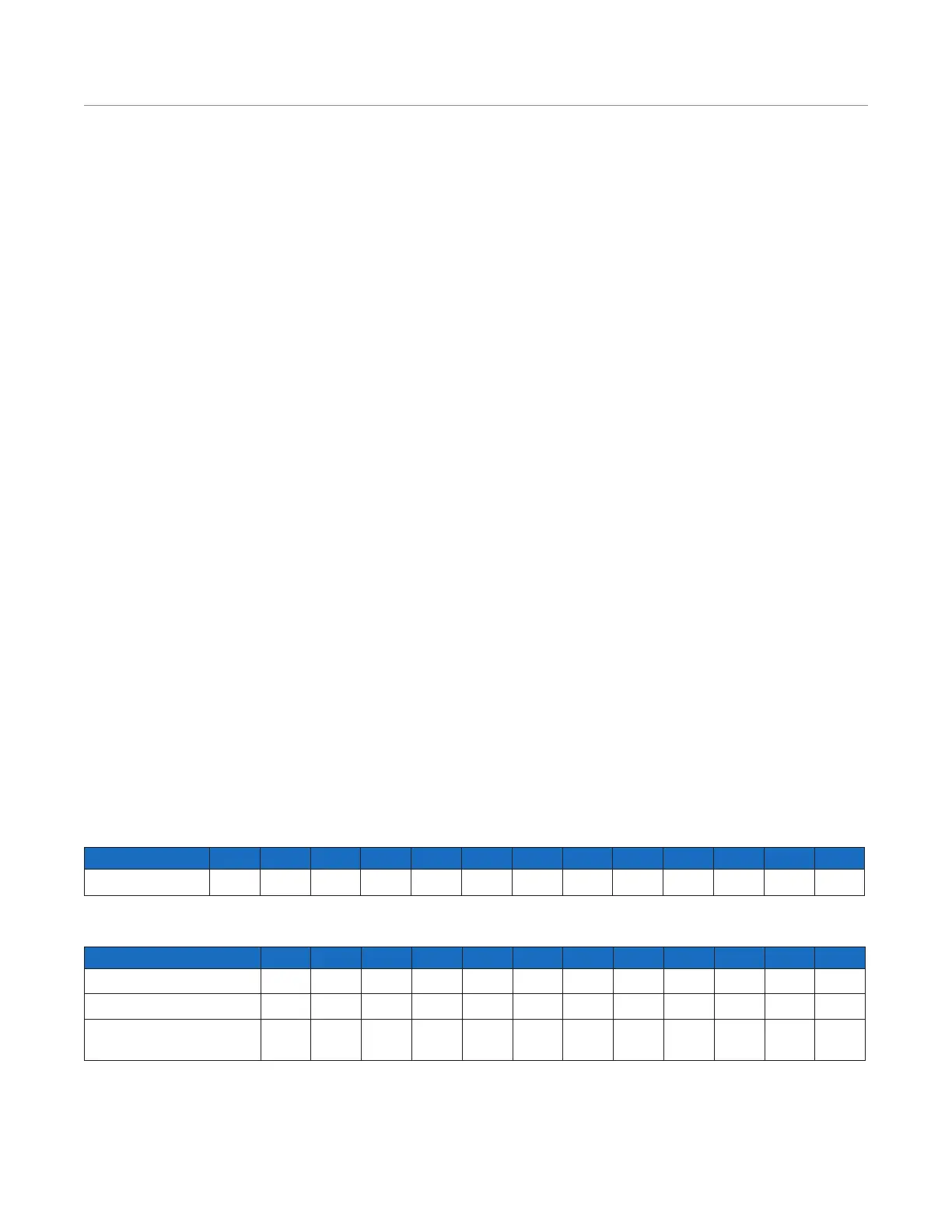

The following chart is provided for a record of routine maintenance procedures. As each procedure is completed

as indicated in the record, either a check, a date, or the user’s initials should be entered in the appropriate box to

record the maintenance procedure as completed.

Biweekly

Week 2 4 6 8 10 12 14 16 18 20 22 24 26

System Backush

Monthly

Month 1 2 3 4 5 6 7 8 9 10 11 12

Timed Addition Calibration

Reaction Vessel Drain Test

View run history reports to

ensure proper heating*

Loading...

Loading...