48

Maintenance of the Liberty Blue

6. The Liberty Blue will prime the line to the reagent manifold (through valve MS1), purge the liquid to the reaction

vessel, then drain the vessel. Next, the Liberty Blue will prime the direct wash line to the reaction vessel

(through valve MS2), then drain the vessel.

Change Bottle Deprotection

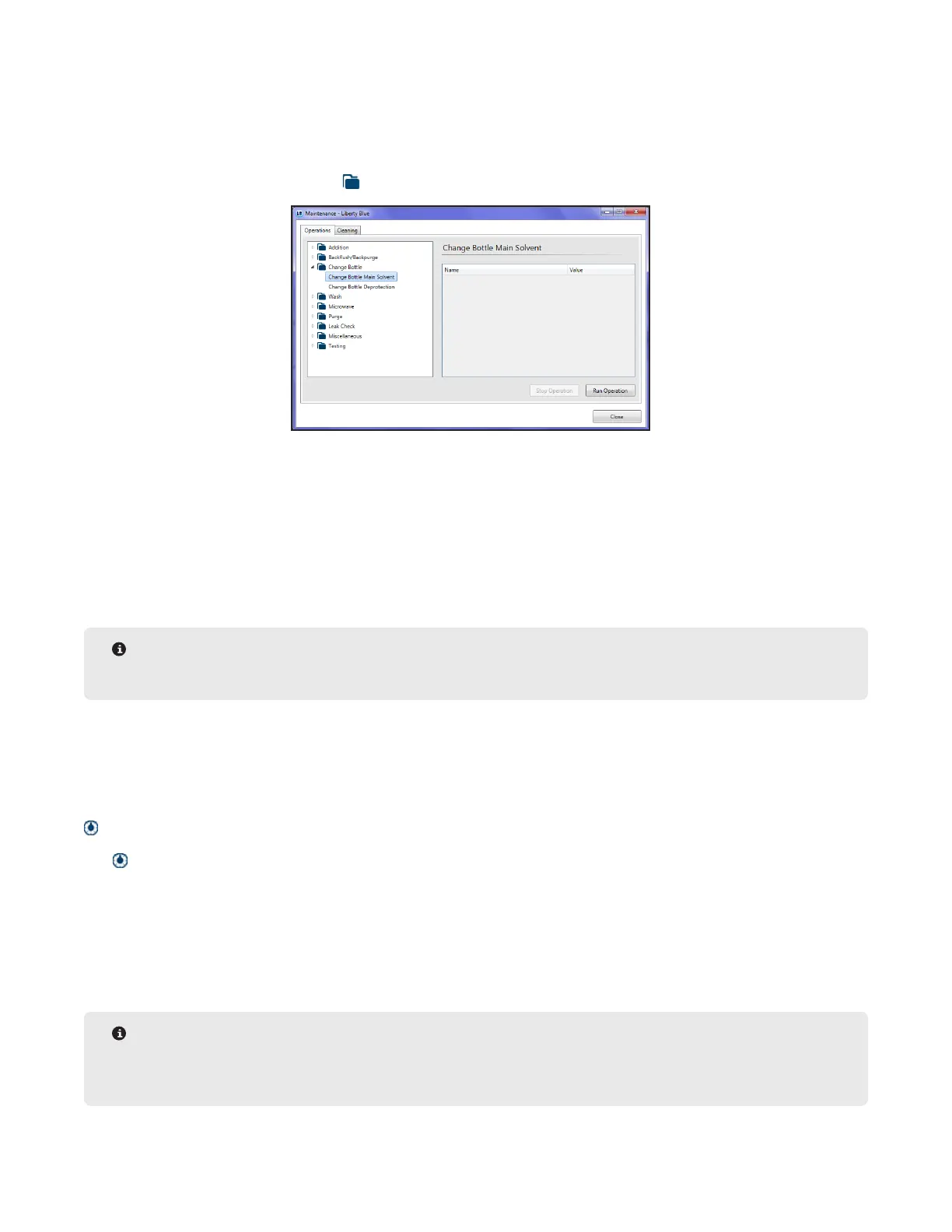

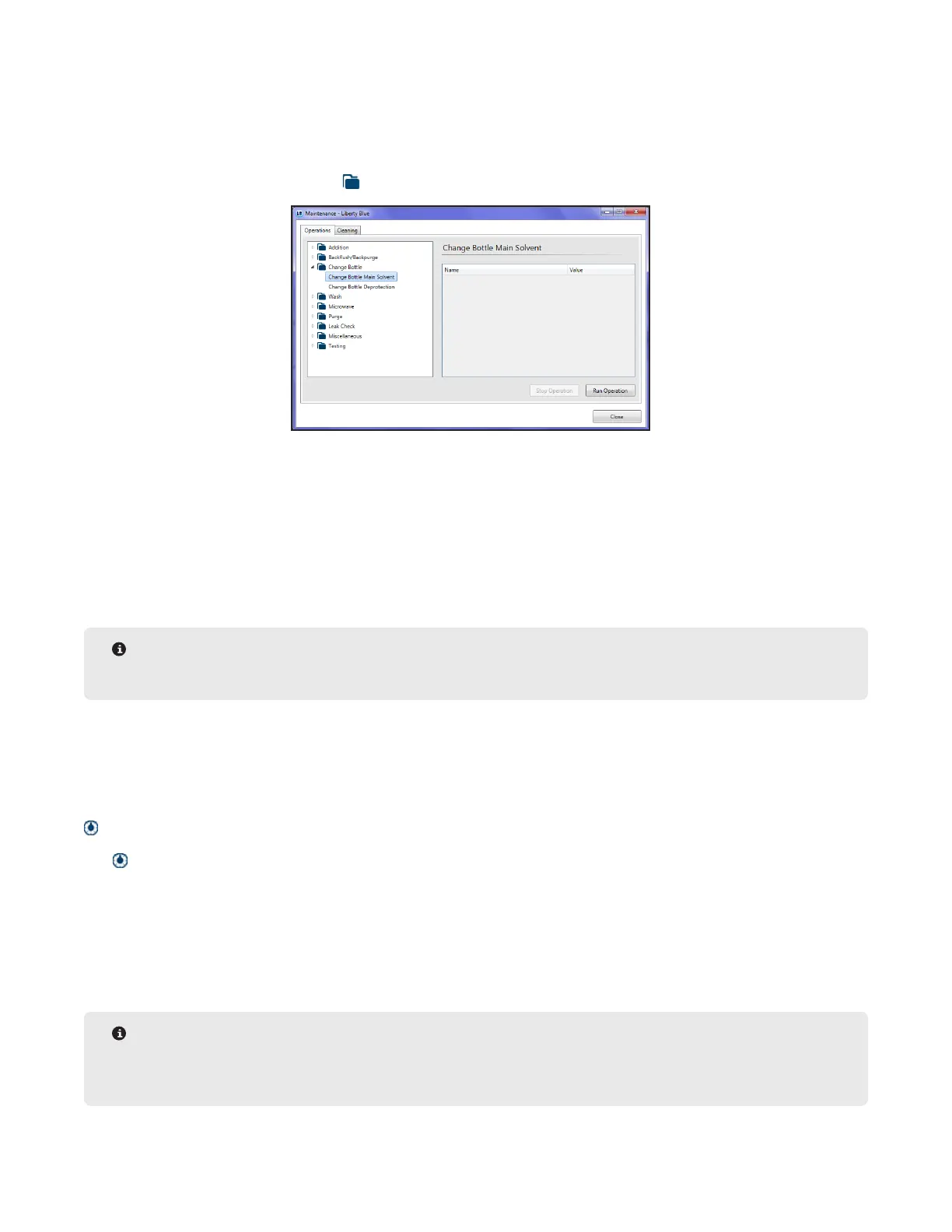

1. From the Operations tab, open the Change Bottle folder and click on the Change Bottle Deprotection operation.

2. Click the Run Operation button.

3. The Liberty Blue will vent the pressure from the deprotection bottle, then clear the lines to the deprotection

bottle.

4. The software will prompt to replace the deprotection bottle. Replace the bottle, then click OK to pressurize the

bottle.

5. The software will prompt to begin priming the lines. Click OK to begin the priming procedure, or click Cancel to

skip priming.

NOTE

The deprotection line must be primed or the rst deprotect addition will not be accurate.

6. The Liberty blue will prime the lines from the deprotection bottle to the reaction vessel, then drain the reaction

vessel.

7. Following the priming, the reaction vessel will be washed and drained.

Calibration Screen

The Calibration screen allows for the calibration of the timed delivery of reagents to the reaction vessel, as well

as all pressure and liquid sensors. The Calibration screen can be accessed from the Options menu.

Timed Addition Calibration

There are four timed additions that must be calibrated for optimal functionality of the Liberty Blue: Wash, Wash

Thru Manifold, Deprotection, and Wash Thru RV Bottom. Timed Addition Calibration should be performed monthly

as part of routine maintenance.

NOTE

Refer to the Timed Addition Protocol. All other calibrations should be performed under guidance of a CEM

representative.

Loading...

Loading...