24

8 Calibration Mode

It is possible to calibrate the controller to compensate

for sensor errors and other tolerance errors in the sys-

tem. This is achieved using the calibration mode. The

calibration mode allows an offset to be applied in one

of two ways. The method used will be dependent on

the process application.

These methods do not alter the internal

instrument calibration. Set the offset

values back to zero to restore standard

measured values. Re-calibration of the

internal base calibration is also possible,

but should only be attempted by qualified

personnel as it overwrites the factory

calibration – see Base Input Calibration

below.

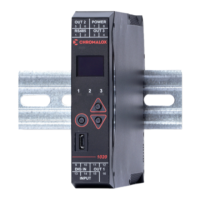

8.1 Single Point Calibration (PV Off-

set)

This is a ‘zero offset’ applied to the process variable

across the entire span. Positive values are added to the

reading, negative values are subtracted. It can be used

if the error is constant across the range, or the user

is only interested in a single critical value. To use, se-

lect Single Point Calibration from the input calibration

menu, and simply enter a value equal, but opposite to

the observed error to correct the reading.

This example shows a positive offset value.

Single Point ‘Offset

Calibration’ value

New Displayed Value

Original Displayed Value

For example: If the process displays 27.8 when it

should read 30, The error is -2.2 so an applied offset

of +2.2 would change the displayed value to 30. The

same offset is applied to all values, so at 100.0 the new

displayed value would be 102.2.

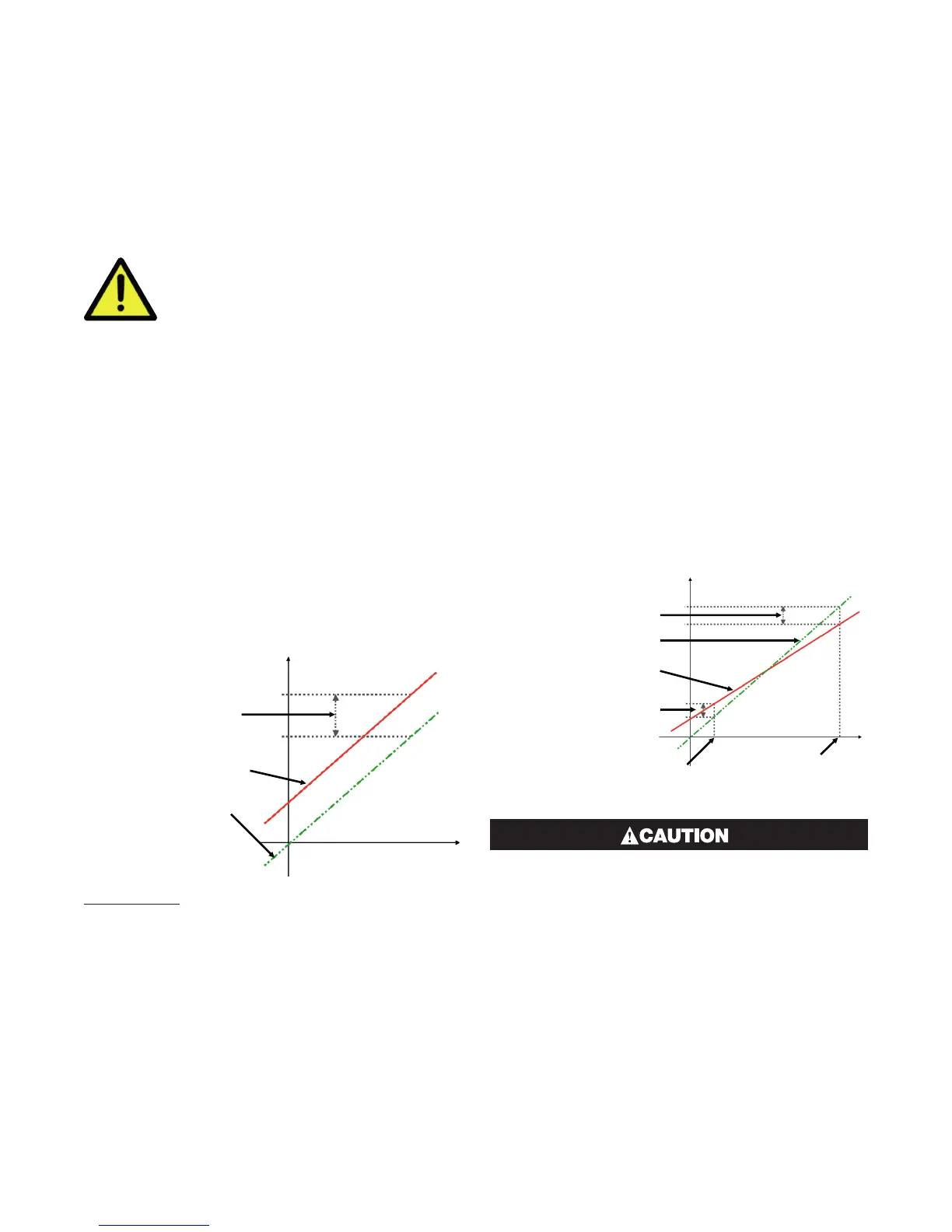

8.2 Two Point Calibration

This method is used where an error is not constant

across the range to change the calibration slop. Sepa-

rate offsets are applied at two points in the range to

eliminate both “zero” and “span” errors.

1. Measure and record the error at a low point in the

process.

2. Measure and record the error at a high point in the

process.

3. Go to the first two-point input calibration screen.

a. Enter the desired low point value as the Calibra-

tion Low PV value.

b. Enter an equal, but opposite value to the ob-

served error as the Calibration Low Offset to cor-

rect the error at the low point.

4. Go to the second two-point input calibration screen.

a. Enter the desired high point as the Calibration

High PV value.

b. Enter an equal, but opposite value to the ob-

served error as the Calibration High Offset to

correct the error at the high point.

New Displayed Value

Calibration High Offset

Calibration Low Offset

Calibration High

Process Value

Calibration

Low Process Value

Original Displayed Value

Choose values as near as possible to the bot-

tom and top of your usable span to achieve

maximum calibration accuracy. The effect of

any error can grow at values beyond the cho-

sen calibration points.

The single and two-point calibration methods can be

used together, if you need to change the calibration

slope and offset the zero point simultaneously.

Loading...

Loading...