34

12.3 Parameter Adjustment

Minimum Cooling

Cooling is enabled only above the temperature set be-

cause evaporation, with its associated cooling effect,

is not possible at temperatures below 100°C. Set this

>100, but it should be well below the normal operating

setpoint.

Note: In manual mode cooling is still possible below

this temperature.

Impulse Length

A fixed length for cooling pulses set by this parameter.

The ON pulses are this length for all cooling output val-

ues above 1% nominal cooling demand.

Relatively low values should be used, but remember that

the ratio of the Minimum Off Time vs Impulse Length

affects the maximum effective cooling (see above). Do

not allow this to limit cooling to the extent that insuf-

ficient cooling effect is available for the process.

The impulse length is also limited by the hardware (e.g.

the response time of your valve). Valves and electro-

mechanical relays should not be switched to quickly.

Consult the device manual or check with your supplier

for suitable minimum settings.

Minimum Off Time

The “off” time between pulses is varied dependent

upon the PID cooling demand. The Minimum Off Time

is the minimum allowed “off” time (but note that below

1% of cooling demand, the output is disabled).

The time set is hardware-dependent (e.g. the response

time of your valve). Generally, it is best set to the lowest

value compatible with the output switching device, but

remember that valves and electromechanical relays

should not be switched to quickly. Consult the device

manual or check with your supplier for suitable mini-

mum settings.

Remember that the ratio of the Minimum Off Time vs

Impulse Length affects the maximum effective cooling

(see above). Do not allow this to limit cooling to the

extent that insufficient cooling effect is available for the

process.

Non-Linear Adjust

This attenuates the cooling curve, and altering where

the output rate begins to increase more rapidly. The val-

ue can be reduced if the corrective action is too severe,

this reduces the non-linearity of the effective output.

To find an appropriate Non-Linear Adjust setting:

First set Minimum Cooling, Impulse Length and

Minimum Off Time to appropriate values (see

above), and initially set Non-Linear Adjust to 5. Use

Pre-Tune or manual tuning to adjust the controllers

PID settings to your process.

Using these settings, and observe the transition

from heating to cooling. If there is a noticeable

over-reaction, where the cooling is still too strong,

increase the Non-Linear Adjust value until the ef-

fect is reduced to acceptable levels. If the transition

becomes too slow, with effective cooling unaccept-

ably delayed, reduce the value set.

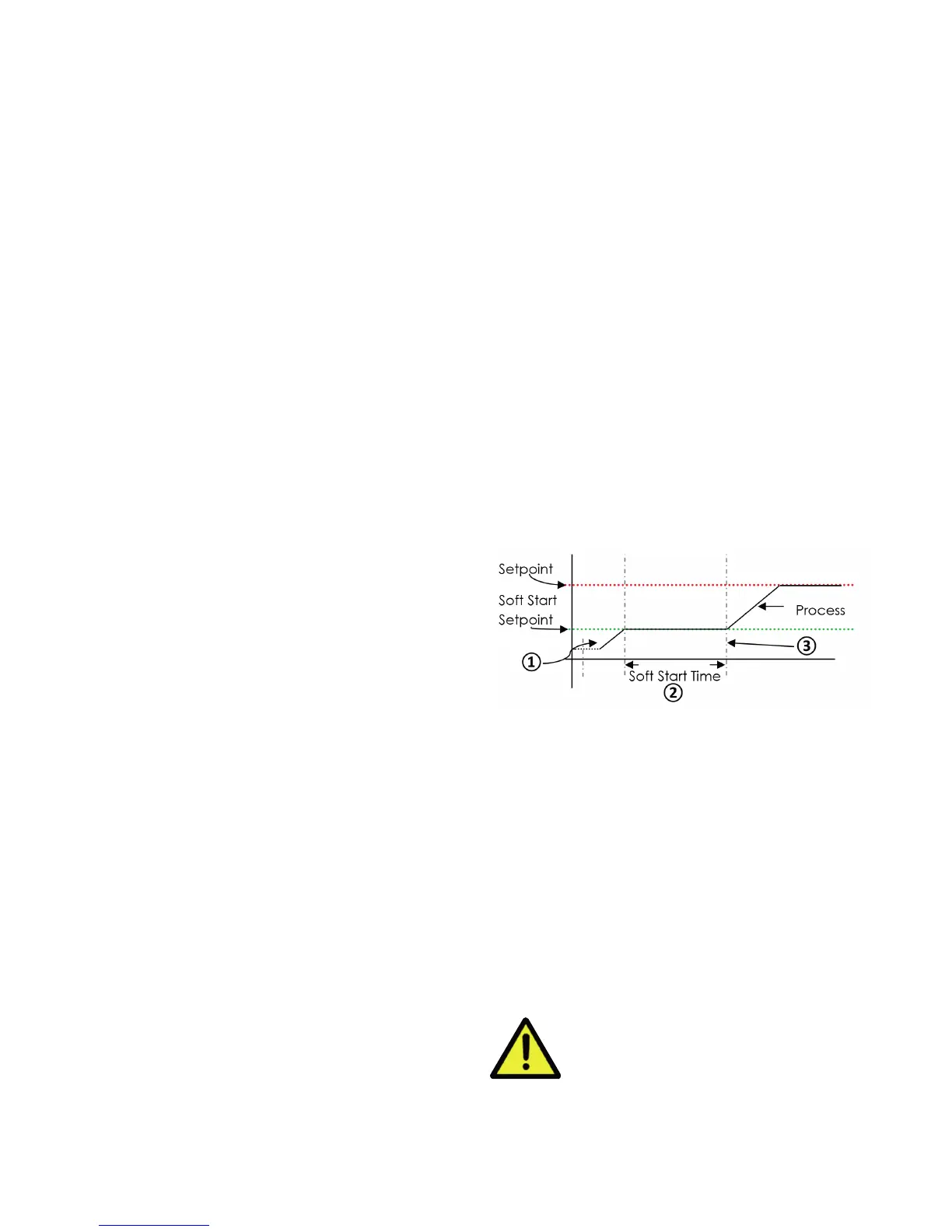

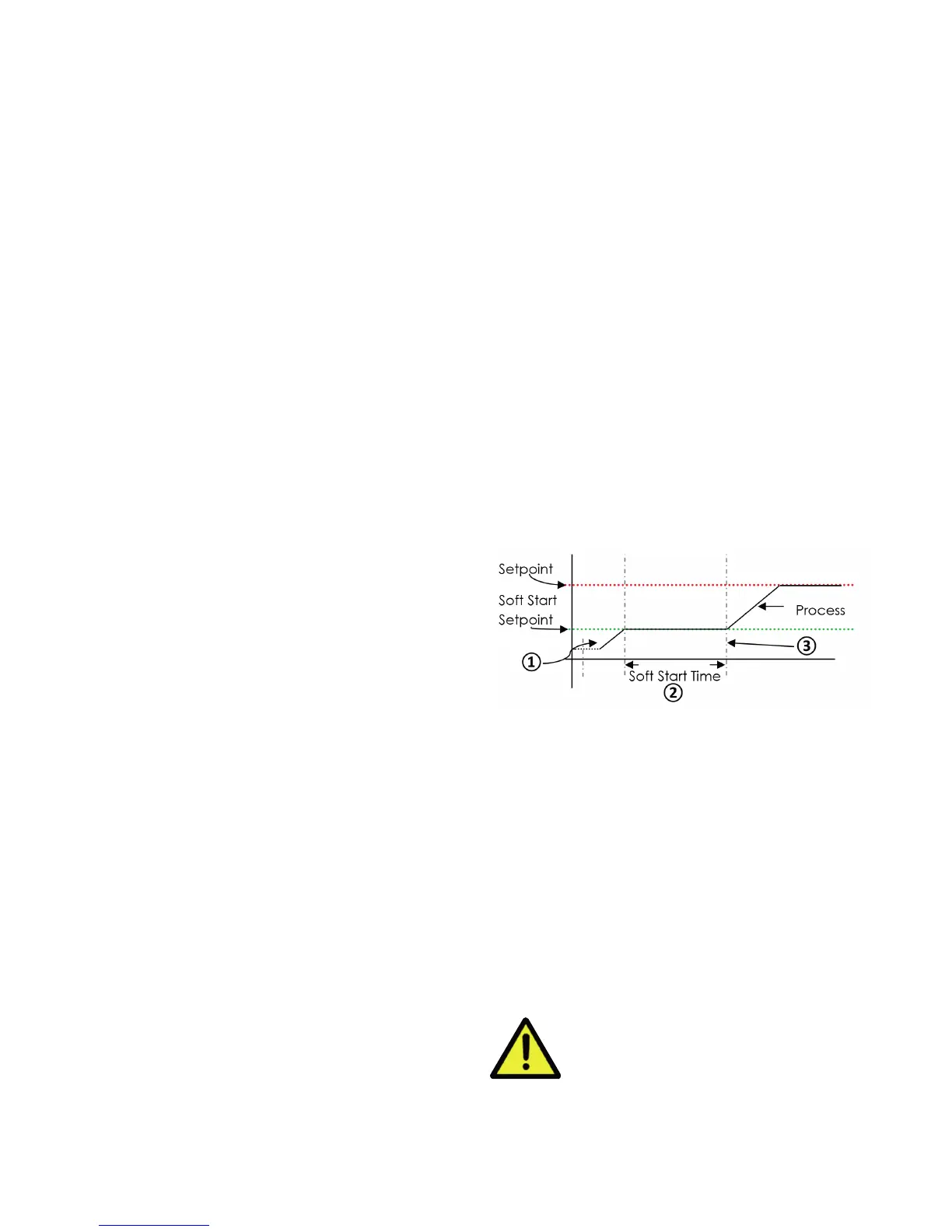

12.4 Soft Start Function

Soft Start is primarily intended to allow heaters to dry

out gradually at start-up condensation which can form

when the heaters are cold can cause damage if it evap-

orates too quickly.

Soft Start has its own setpoint, allowing a pre-defined

low-temperature dwell period which reduces the power

demand from the heaters, allowing moisture to evapo-

rate more slowly before going to full working tempera-

ture. During this period, it also minimizes the heater-on

times by reducing the cycle time and limiting the PID

power demand.

Note: Soft Start does not limit the instantaneous cur-

rent to the heaters when the output is on.

Activated by setting the parameters Soft Start Time

and Soft Start Setpoint.

1. When powered up the unit will control to the Soft

Start Setpoint. The control cycle time is 1/4 of the

value entered (subject to the minimum possible

value of 0.5s) and the maximum power demand is

limited to the Heat Power Limit value (set in the

Control menu). The reduced cycle time is used dur-

ing the soft start phase.

2. After reaching the Soft Start Setpoint the Soft Start

Time begins. The timer starts as soon as the PV is

equal to Soft Start Setpoint – 1. The Soft Start Set-

point is maintained until this time has elapsed.

3. When Soft Start Timer expires, the unit returns

to normal operation. It controls to the normal set-

point, the cycle time reverts to the value set and the

Heat Power Limit is no longer used.

Remember, when using the Soft Start

feature the Heat Power Limit is only

active from power-on and during the Soft

Start Time. It remains in use until the Soft

Start timer expires or all the time if no

Soft Start time is OFF.

Loading...

Loading...