25

8.3 Base Input Calibration

Calibration of the input is carried out during manufac-

ture, and for most applications, re-calibration is not

required during the lifetime of the instrument. User

1-point and 2-point calibration can be carried from the

User Calibration menu.

Re-calibration of the internal base values

is possible, but should only be attempted

by qualified personnel as it overwrites

the factory calibration.

A suitable calibration signal source is required for each

input type. To verify the accuracy of the instrument or

carry out re-calibration, the input sources listed below

are required, with better than ±0.05% of the reading

accuracy:

1. DC linear inputs: 0 to 50mV dc, 0 to 10V dc & 0 to

20mA dc.

2. Thermocouple inputs - complete with 0ºC reference

facility, appropriate thermocouple functions and

compensating leads (or equivalent).

3. RTD inputs: decade resistance box with connec-

tions for three-wire input (or equivalent).

8.4 Calibration Check

1. Set up the instrument to the required input type.

2. Note down, then remove any single or two-point

calibration values by setting them to zero.

3. Power up the instrument and connect the correct

input leads, to the correct terminals.

4. Leave powered up for at least five minutes for RTD

and DC linear inputs, or at least 30 minutes for ther-

mocouple inputs.

5. After the appropriate delay for stabilization has

elapsed, check the calibration by connecting the

appropriate input source and checking a small

number of cardinal points.

6. Repeat the test for all required input types.

7. Check the results against the specification stated

for the required input type.

8. Reinstate the calibration values removed at step if

they are still appropriate.

Make the connections using the correct ther-

mocouple cable type. For all other input types

use copper cable. Using the wrong type of ca-

ble will cause incorrect readings. This is espe-

cially important with thermocouple sensors.

8.5 Base Calibration Procedure

Input calibration is carried out in five phases as shown

below, each phase corresponds to an input range of

the instrument.

The 50mV phase must be calibrated first be-

fore any other range(s).

Calibration phases:

i. mV for 50 mV

ii. V for 10 V

iii. mA for 20 mA

iv. RTD input (200Ω ohm resistance source)

v. CJC (K type thermocouple source at 0ºC required)

For Extrusion models phase ii and iii (V & mA) are omit-

ted.

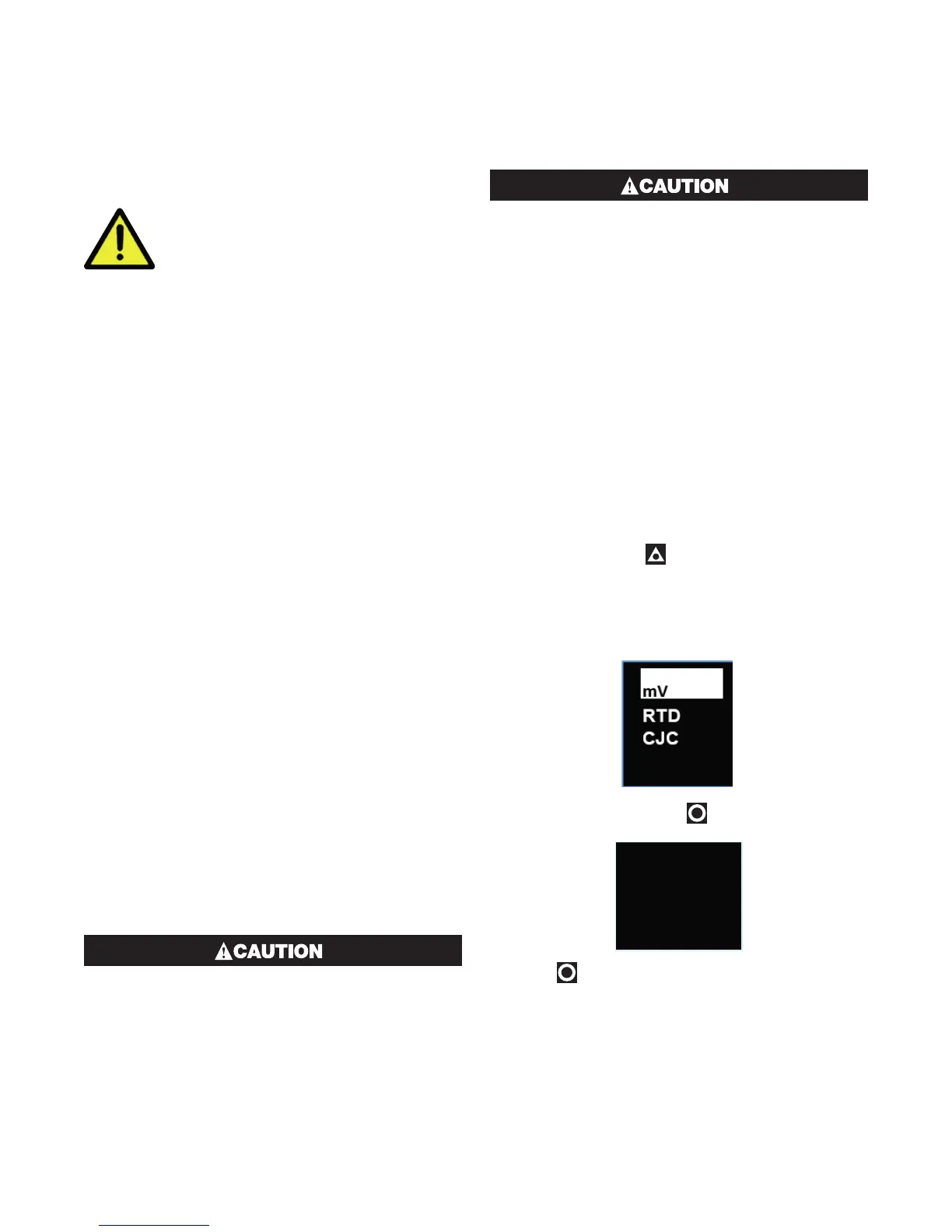

8.6 Calibrating the mV Input

1. Check your calibration source is connected to the

correct terminals on the 1020 Rail. For 50mV, con-

nect your mV source +ve to pin 14 and -ve to pin 15

located on the bottom rear connector – see wiring

section.

2. Press and hold the button, whilst the instrument

is powering up, until the display shows the screen

starting with mV. Be patient, may take approximate-

ly 30 seconds.

3. In the calibration phase menu displayed, highlight

mV from the list.

>mV Input

userCAL

Press enter

to start

4. With mV selected, press . The following screen

will appear:

>mV Input

userCAL

Press enter

to start

5. Press . You should see the messages Starting

Calibration, followed by Calibration in Progress.

A dot moves across the display to show the prog-

ress.

6. If the input is wrongly connected or an incorrect sig-

nal is applied the calibration will be aborted and the

display will show Calibration FAIL. The previous

calibration value will be retained.

Loading...

Loading...