3-2012

Plus 42 - 45 - 50 - 55

21

Furthermore, by opening the handle tap (P12) of the dust powder mixer,with manual distributor (P9)

or electrical distributor (E9) closed, it is possible to carry out the product mixing.

A different momentary positioning of the lever is required at times, but only for certain operations that

will be specified from time to time.

b. POWDERS’ MIXING (Horizontally, rightwards)

Only the mixing of powder products is to be carried out in this position

The pump delivery is sent to the filter (P7). By opening the faucet (P12) and closing the distributor (P9

or E9), the delivery is sent to the mixer (P13) of the main pipe union.

The flow to the tank is closed, through the regulator (P5) and (T2) and the delivery

towards the distribution device (sprayhead), therefore there is no delivery and it is not

possible to do the treatments. The hydraulic agitation is partially maintained through the

additional agitation pipeline (T9)

c. DETACHMENT/REATTACHMENT OF THE FILLING PIPE (Vertically, upwards)

The flows towards piping (T2) is interrupted.

This is to be positioned AT THE END of the tank’s filling operation, before disconnecting

the filling up piping. (TR) (accessory). NEVER OPERATE THE SPRAYER WITH TAP (P6)

IN THIS POSITION.

d. FILTER MAINTENANCE (Horizontally, leftwards)

The flow to piping (T2) is open. The capacity flow towards filter (P7) and to the feeding circuit is closed.

This allows the cleaning of filter (P7) even with a full tank; check that tap (P12) is closed.

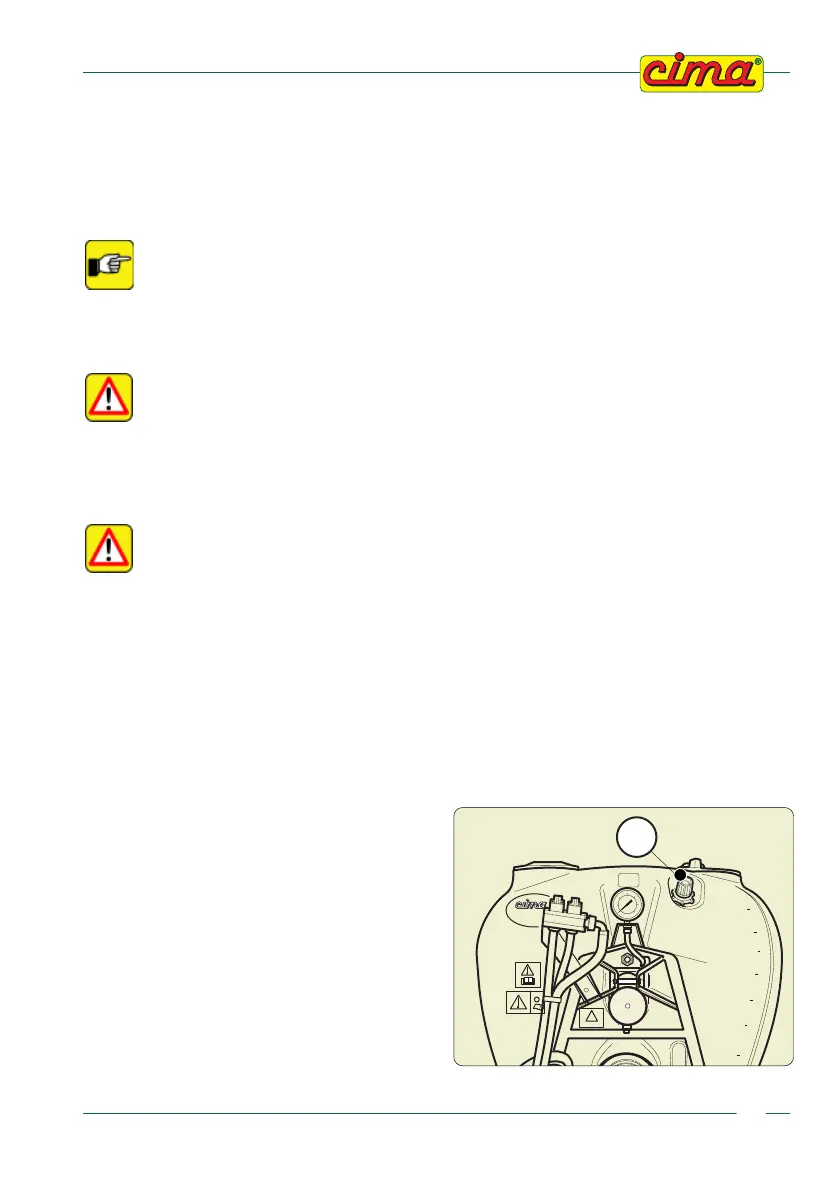

P5. MANUAL PRESSURE REGULATOR

It is mounted on the tank and is connected to tap (P6) through piping T2. It regulates the operating

pressure by controlling the return flow to the tank.

00186

350

300

250

200

150

100

50

50 Pl

P5

— By closing it: it REDUCES the return flow

to the tank and therefore, the agitation of the

mixture, and it increases the operating pres-

sure and capacity flow to the head (rotate the

handle clockwise).

— By opening it: it INCREASES the return

flow to the tank and therefore, the agitation

of the mixture, while reducing the operating

pressure and capacity flow to the head (rotate

the handle anti-clockwise).

Loading...

Loading...