3-2012

Plus 42 - 45 - 50 - 55

49

10.5 - END OF TREATMENT - STORAGE

10.5.1 - Daily

The operator must:

if the machine is equipped with unit-washing tank:

a. carry out the hydraulic circuit washing process (see paragraph 10.4) spraying on the piece of

ground treated yet. Attention: to make to spray the sprayer for around 5 sec..

b. Wash the inside of the tank:

1. Disengage the fan (for the version where foreseen): see point 8.1.a.

2. Close the taps of the 2-way distributor:

- if electrical, position the latch switches (E10).on “OFF”

- if manual (P9), set the levers in the horizontal position;

3. Close the pressure regulator completely, by rotating the hand regulator (P5) handle clockwise

or by turning the pressure up (keep the joystick on “+” for about 15 seconds) for the versions

with electrical pressure regulator (E5)

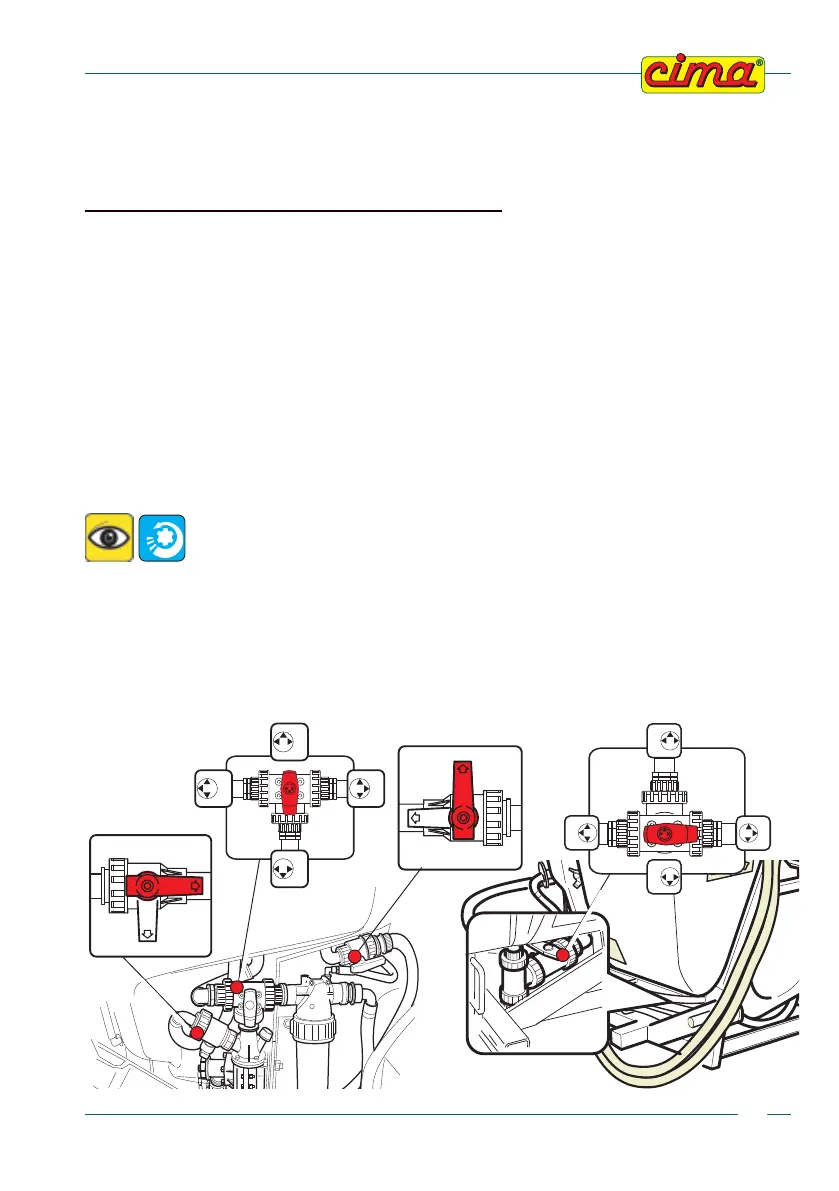

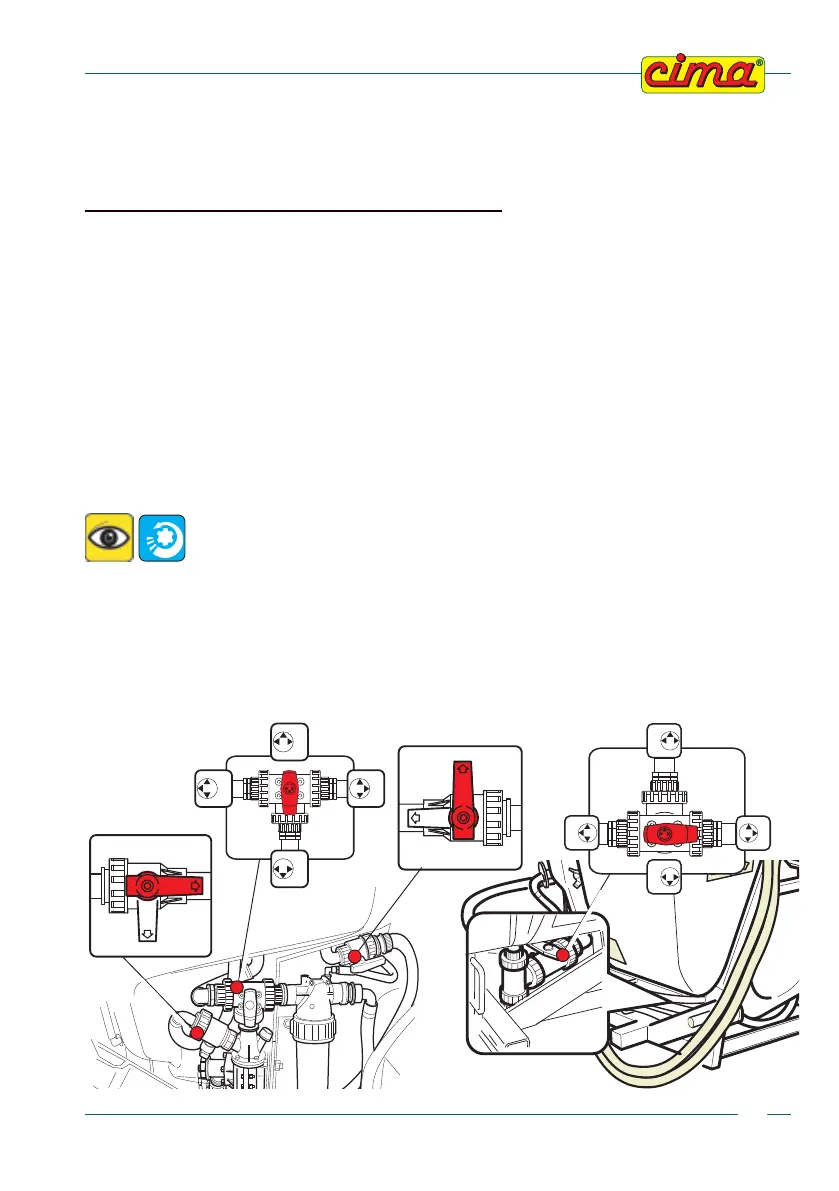

4. Close the faucet (P3) of exclusion of the additional agitation, ever on “c”.

5. Put the thee-way faucet (P6) in “B” position.

6. Put the cock (P15), in to position “B” (washing);

7. Engage the drive outlet (PTO) and take it to a speed of 540 RPM

540

Use ONLY the PTO at 540 rpm. Engage the PTO with the engine of the tractor

at low speed and with maximum modularity, obtaining soft and progres-

sive graft and avoiding abrupt starts of the cardan shaft.

8. Open the tap (P12), lever on “a”.

9. Rinse the tank untill the water in the spray-line ringsing tank is totally run out.

10. Disengage the drive outlet (PTO).

11. Close the tap (P12), lever on “c”.

11a. Discharge the rinsing water in area with a drain basin and arrange the waste following the

country rules.

d

b

a

c

c

a

P12

P6

c

a

P3

d

b

a

c

Loading...

Loading...