3-2012

Plus 42 - 45 - 50 - 55

25

E10. CONTROL UNIT

(for versions provided with)

It is electrically connected to the distributor with 2

motorised solenoid valves (E9) and to the main

socket of the tractor (Lighter tap).

The 2 lever switches, controlling the solenoid

valves (E9), have to be set to “ON” for opening

and to “OFF” for closing. The control unit is

equipped with a bayonet support to be inserted in

the bracket provided. This must be mounted on

the tractor, within the driver’s reach. When the

machine isn’t hitched to the tractor, it must be

00907

1

2

2

3

00026

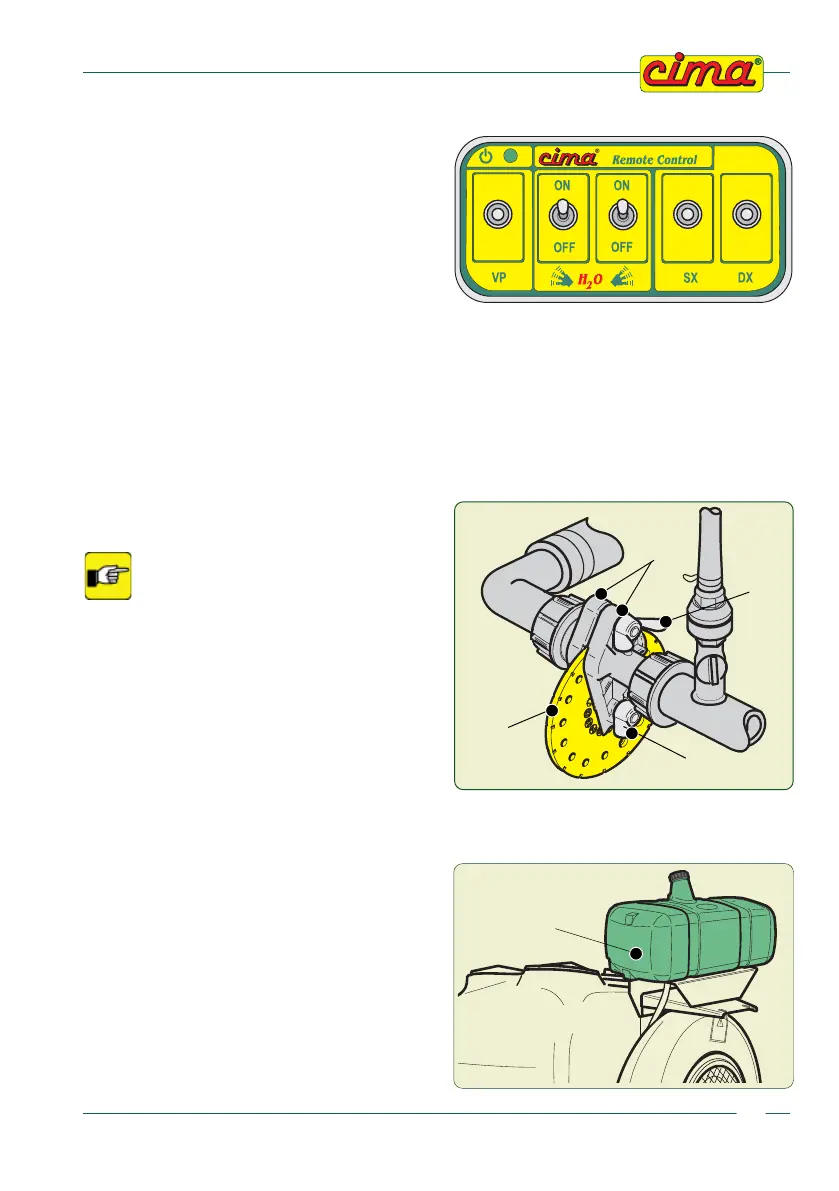

butterfly nuts by a few turns. After the operation is

done, screw back carefully.

Any faulty sealing condition of the

hydraulic circuit causes an intermittent

issuing of the sprayed material. It is

necessary to carefully check the

efficiency of the sealers and clamps,

the tightening of the ring nuts and

fittings and the good working condition

of the piping.

placed in the position foreseen on the forward part of the machine frame.

P11. CALIBRATION DISC (Patent N° 23238)

It selects the flow rates necessary to the treatment and is mounted on the distribution devices. It is made

up of 2 flanges, held in position by two butterfly nuts, locking a disc with calibrated holes numbered from

1 to 15. A groove on the edge of the disc allows the exact positioning of the hole to be utilised. Its number

must appear in the flange’s semi-circular seat. The rotation of the disc is obtained by loosening the

SPRAY-LINE

RINSING

TANK

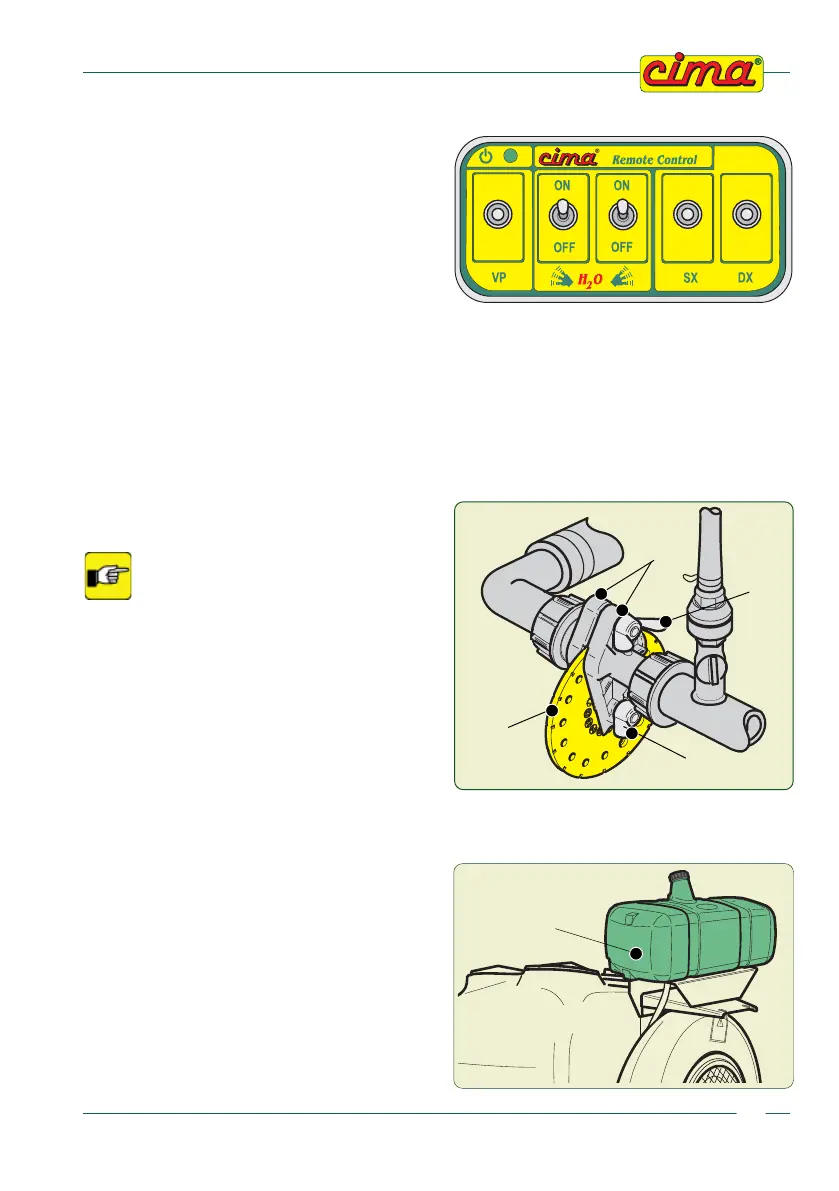

P17. SPRAY-LINE RINSING TANK

(for versions provided with)

The tank, 45 liters capacity, is made of polyethy-

lene and is supplied with a filler and pipelines

connecting to the machine hydraulic circuit.

LEGEND

1 - UNION FLANGES

2 - LOCKING NUT

3 - ROTATING DISC WITH CALIBRATED HOLES

Loading...

Loading...