Section 5 — Service and Maintenance

Part No. 750-263 5-3

B. REASSEMBLY

1. Assembly is the reverse of the above instructions.

2. A new rope gasket should be installed on the burner door.

See recommended spare parts list.

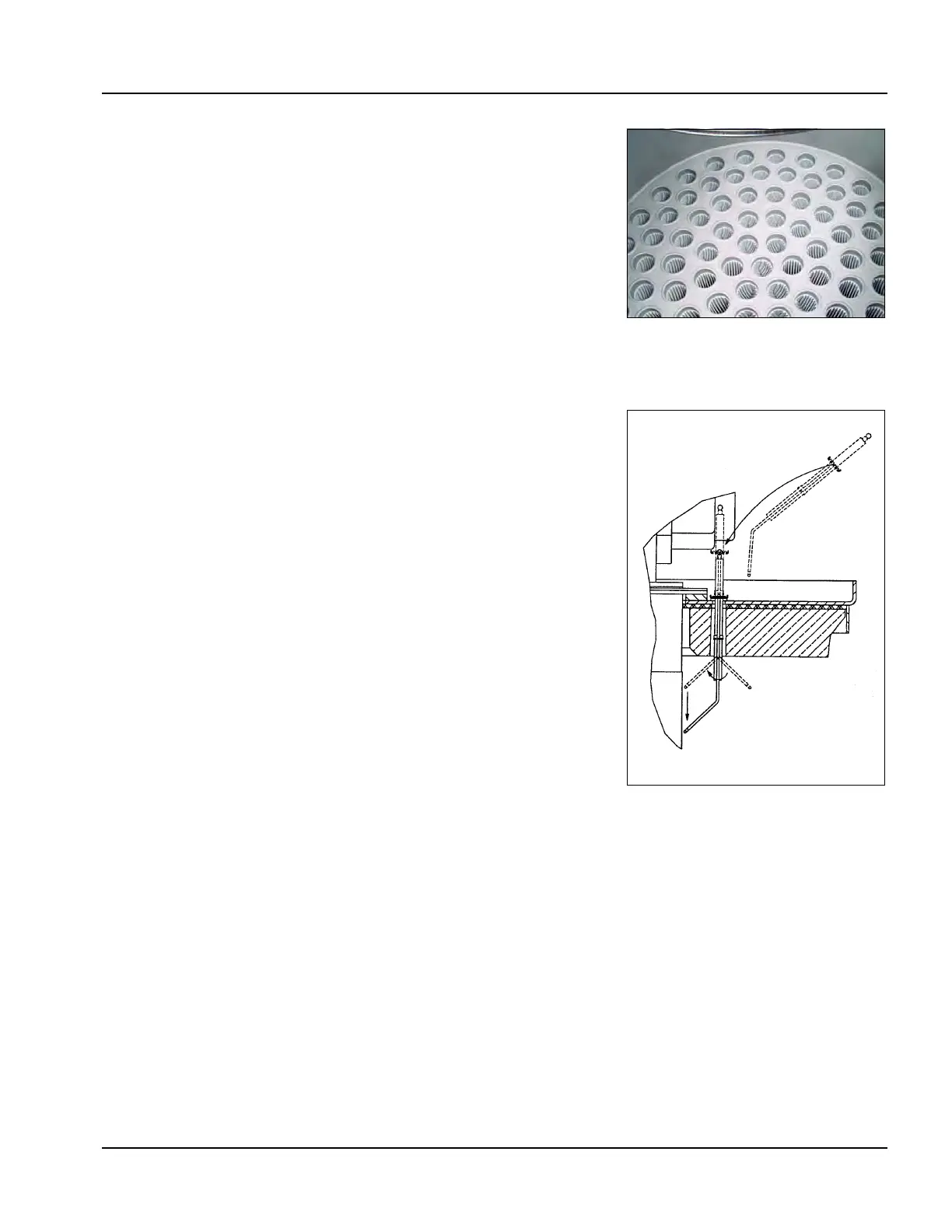

C. IGNITION ELECTRODE AND FLAME ROD

The ignition and ionization electrodes should be replaced annually,

or more frequently if conditions require. Inspect the electrodes

periodically for signs of fouling, displacement, or other damage.

Electrodes should be replaced as shown in Figure 5-4 with the

electrode turned towards the burner mantle after it is inserted into

the burner head. Observe the dimensions below when replacing

(also see Figure 5-5):

3/8” gap between ionization electrode and the surface of the burner

canister.

1/8” gap between ignitor electrode and ground electrode.

7/8” from ignitor electrode to the burner canister.

D. TROUBLESHOOTING

Lockout Conditions

1. Observe lockout code and description - refer to CB Falcon appendix if

necessary.

2. After determining lockout condition, investigate possible causes.

3. When cause is diagnosed, remedy condition.

4. Reset control. Boiler should be able to start normally.

5. If lockout recurs, further investigation is required. Repeat steps 1

through 4 as needed. If necessary, contact your CB service representa-

tive for technical support.

EXAMPLE: Lockout 79 Outlet Temperature High Limit

1. Before resetting control to clear lockout, check for sufficient water flow

through boiler. Possible sources of insufficient flow include closed

water valves, insufficient pump speed, air trapped in boiler (inadequate

air venting), or modulation set point and off point close to outlet high

limit setting.

The CB Falcon system display/interface provides extensive boiler

diagnostic data at the time of lockout that can help in determining

Figure 5-3 Combustion

Chamber and Tube Sheet

Figure 5-4 Electrode Setup

Loading...

Loading...