Section 4 — CFC Commissioning

Part No. 750-263 4-25

K. PROCEDURES FOR LP (PROPANE) GAS

• Minimum LP gas pressure required is 11" W.C. at 700' ASL.

Pressure correction required for high altitudes.

• Maximum gas pressure rating of the gas train is 1 psig.

Notice

When changing fuels, ensure the CB Falcon has been configured with

the proper fan speed settings for the fuel being used. See Ta b le 4-1 .

1. Single fuel units

1. Close upstream manual gas shut-off valve. Disconnect power

from the boiler.

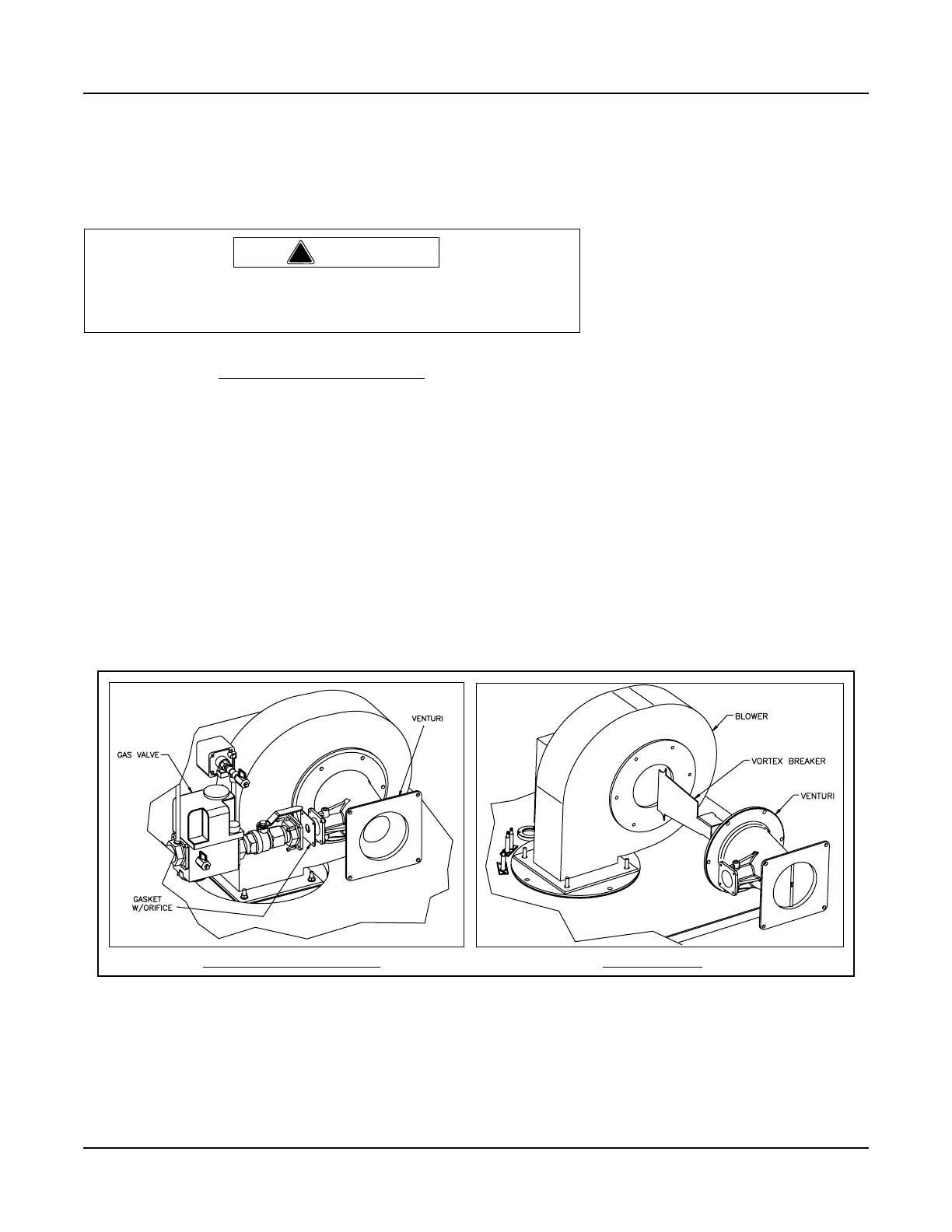

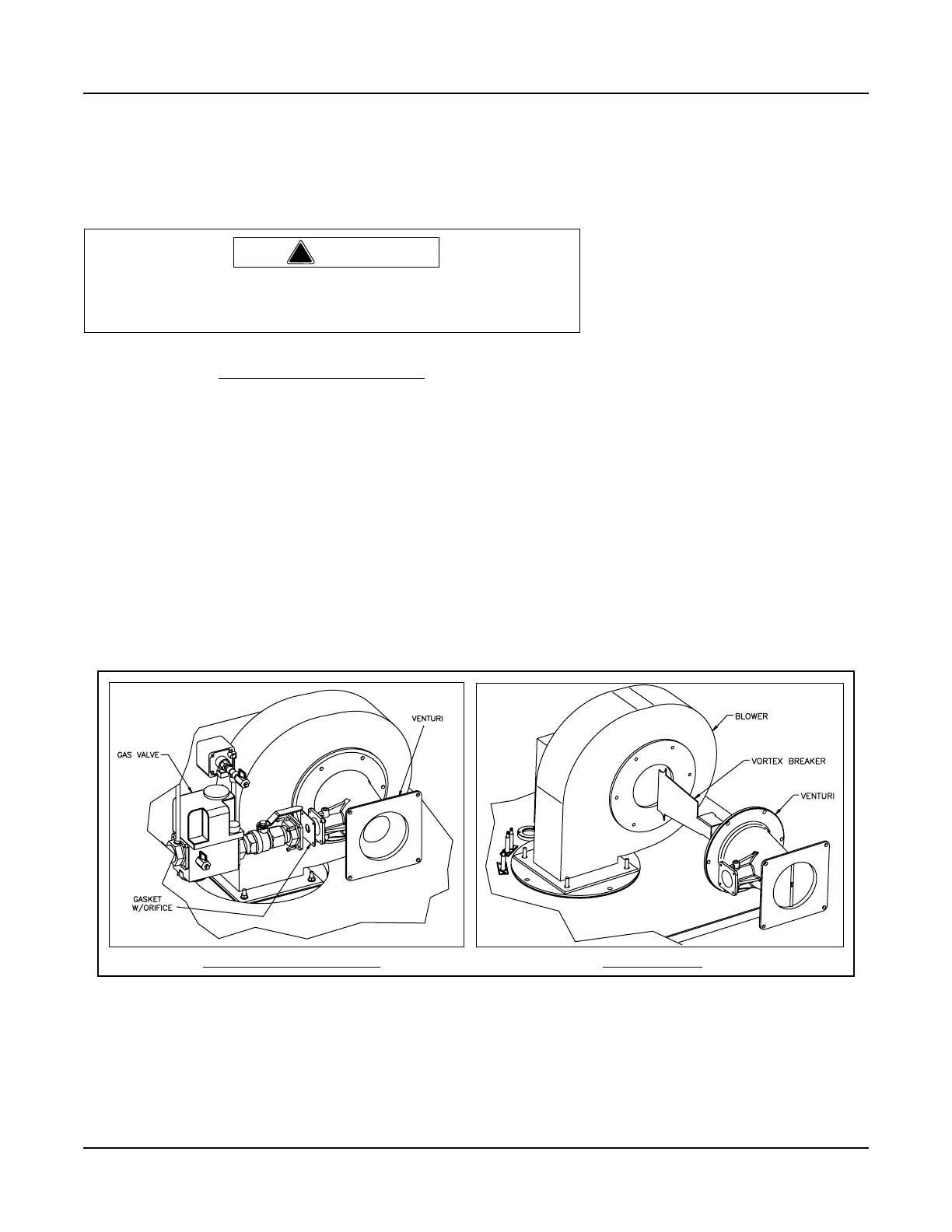

2. Install orifice gasket provided by replacing the existing venturi-

gas train connection gasket with appropriate orifice (see Tabl e

4-4). Install the vortex breaker (CFC-2500 only) between

venturi and blower with the main body of the vortex breaker in

the vertical position. Ensure gas train-venturi connection is

secure and gas tight. Ensure venturi-blower connection is tight.

Figure 4-10 LP Gas Setup - Single Fuel

3. Connect power to the boiler. Power up the controls.

4. Access boiler control Configuration menu. Press <Login>.

Enter service level password: 9220. Press <OK>.

5. Select Modulation configuration. Adjust CH and DHW maximum

modulation rates according to Ta ble 4- 1 . Adjust minimum

!

Warning

Ensure that proper LP gas piping standards and practices are

followed and that the LP gas is properly vaporized. Failure to do so

can result in serious injury or damage to the boiler.

CFC-1800 & CFC-2500 ONLY

CFC-2500 ONLY

Loading...

Loading...