Section 1 — Introduction

Part No. 750-263 1-3

B. STANDARD EQUIPMENT

1. The Boiler

The boiler is designed for a Maximum Allowable Working Pressure

(MAWP) of 125 psig (8.6 Bar) in accordance with the ASME Code

for Low Pressure Section IV Hot Water Boilers and is stamped

accordingly. Operating pressure shall be less than 112 psig (7.7

Bar).

The vessel is mounted on a steel base with insulation & casing

provided including trim and controls. Trim and controls include

safety relief valve, pressure/temperature gauge, probe type low

water control, and CB Falcon hydronic boiler control with associated

sensors..

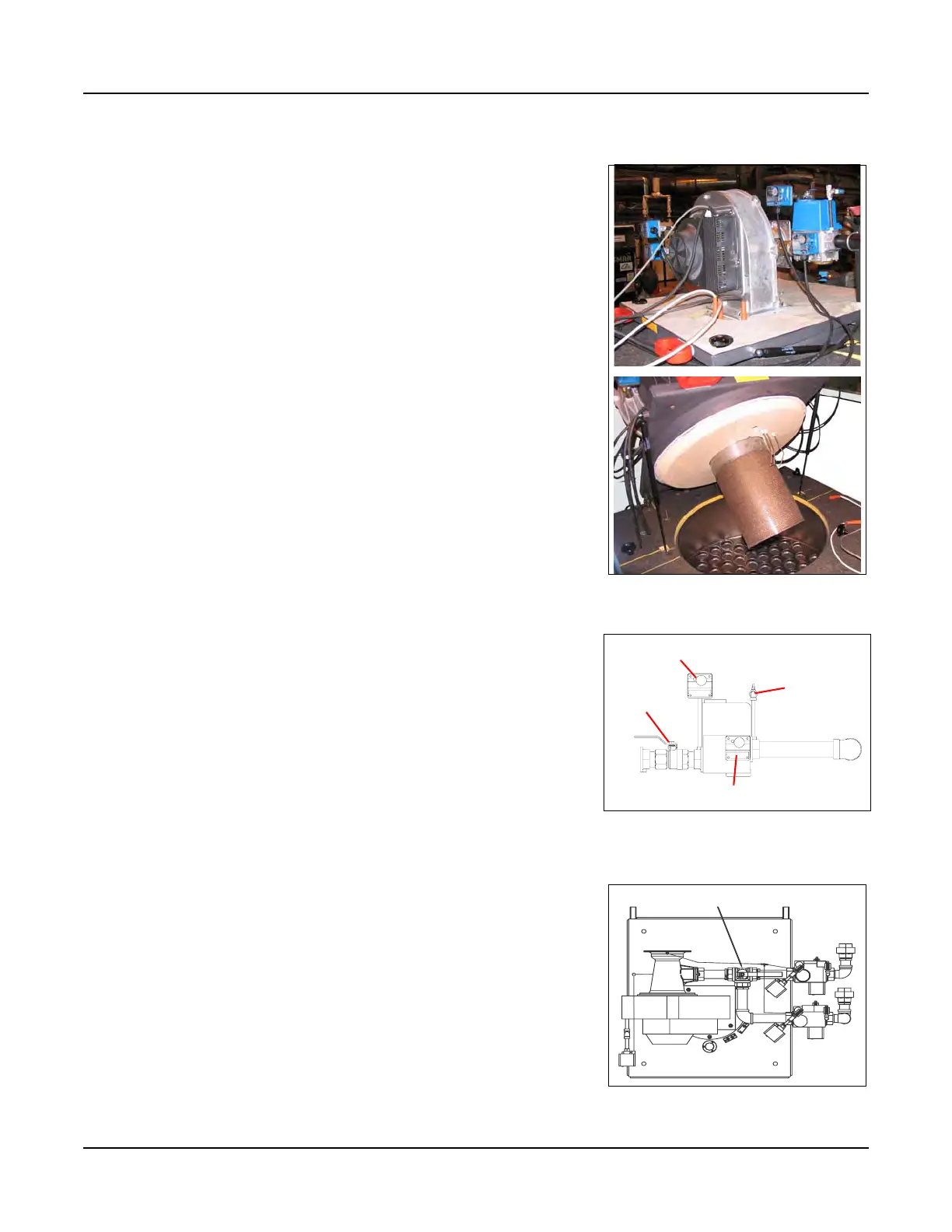

2. The Burner (See Figure 1-4)

Incorporating "premix" technology, the burner utilizes a venturi, dual

safety shutoff-single body gas valve, variable speed blower, and

Fecralloy metal fiber burner head.

Integral variable speed combustion air fan provides 5:1 turndown.

Combustion canister of the burner is constructed of a Fecralloy-

metal fiber for solid body radiation of the burner flame, which

provides low emissions.

At maximum firing rate, the sound level of the burner is less than

70 dBA, measured in front of the boiler at a distance of 3 feet.

Provision for direct vent combustion is furnished.

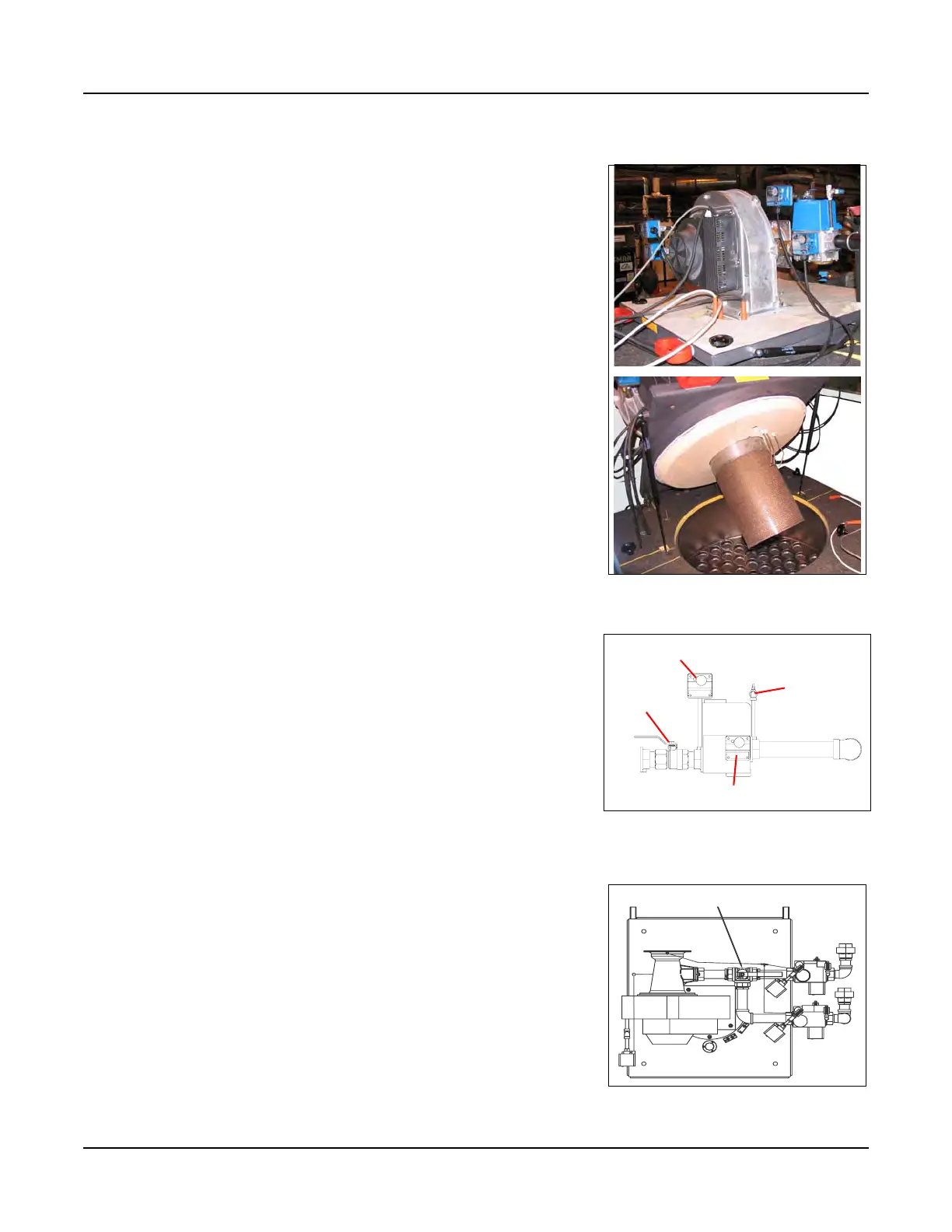

3. Burner Gas Train (See Figure 1-5 & Figure 1-6)

The gas train assembly is provided in accordance with UL

certification and complies with ASME CSD-1. The gas train

assembly is factory assembled and wired, consisting of the

following components:

A. Low Gas Pressure Switch - manual reset

B. High Gas Pressure Switch - manual reset

C. Single body, dual safety shutoff gas valve with integral trim

regulator

D. Integral Venturi

E. Manual Shutoff Ball Valve

F. C S D - 1 Te s t C o c k s

Figure 1-4 Burner

Figure 1-5 Standard Gas Train

High Gas Pressure Switch

Low Gas Pressure Switch

Manual Shutoff

Test C o ck

Figure 1-6 Optional dual gas train

Gas Shutoff / Selector Valve

Natural

Gas Train

Propane

Gas Train

Loading...

Loading...