Section 2 — Installation

Part No. 750-263 2-15

Clean combustion air is required for optimum efficiency and boiler

operation. Dust and airborne contaminants will adversely effect

burner performance. If conditions dictate, a serviceable filter must

be placed in the intake piping to eliminate airborne contamination

to the burner. An optional air filter is available from Cleaver-Brooks.

Additionally, if a direct vent combustion air intake vent is used the

intake should be directed to eliminate rain or snow from entering the

intake piping. The boiler must be installed so that the gas ignition

system components are protected from water (dripping, spraying,

etc.) during appliance operation and service.

F. GAS CONNECTIONS

1. General

The ClearFire Model CFC gas fired condensing boilers are full

modulating input units that require appropriate gas supply pressure

and volume for proper operation. The gas requirements specified in

this section must be satisfied to ensure efficient and stable

combustion. Installation must follow these guidelines and those of

any local authorities having installation jurisdiction.

2. Gas Train Components

CFC boilers are equipped with a gas train that meets the

requirements of ASME CSD-1, FM and XL-GAP (formerly IRI). The

gas train and its components have been designed and tested to

operate for the highest combustion efficiency for the CFC units.

3. Gas Pressure Requirements

For proper and safe operation, each CFC Series boiler requires a

stable gas pressure input. See Ta ble 2- 3 for pressure requirements.

Actual gas pressure should be measured when the burner is firing

using a manometer at the upstream test port connection on the

main gas valve. For a multiple unit installation, gas pressure should

be set for a single unit first, then the remaining units should be

staged on to ensure that gas pressure drop is not more than 1" w.c.

and never below the required pressure. Fluctuating gas pressure

readings could be indicative of a faulty supply regulator or improper

gas train size to the boiler.

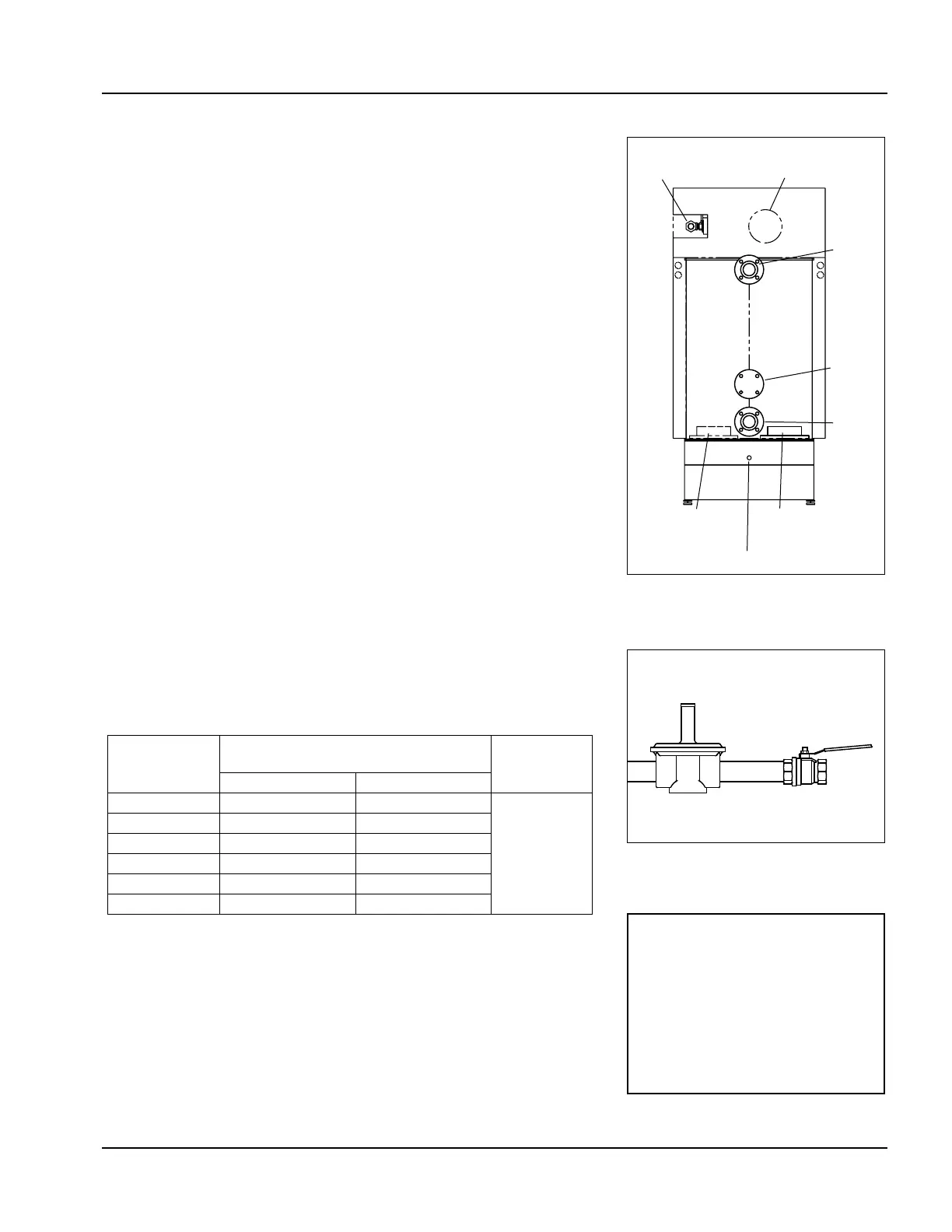

Figure 2-20 CFC Rear View

Gas

Connection

Air Inlet

Extension

Hot

Water

Out

Flue Gas

Vent Connection

Alternate

Flue Gas

High

Temp.

Return

Low

Temp.

Return

Condensate Drain

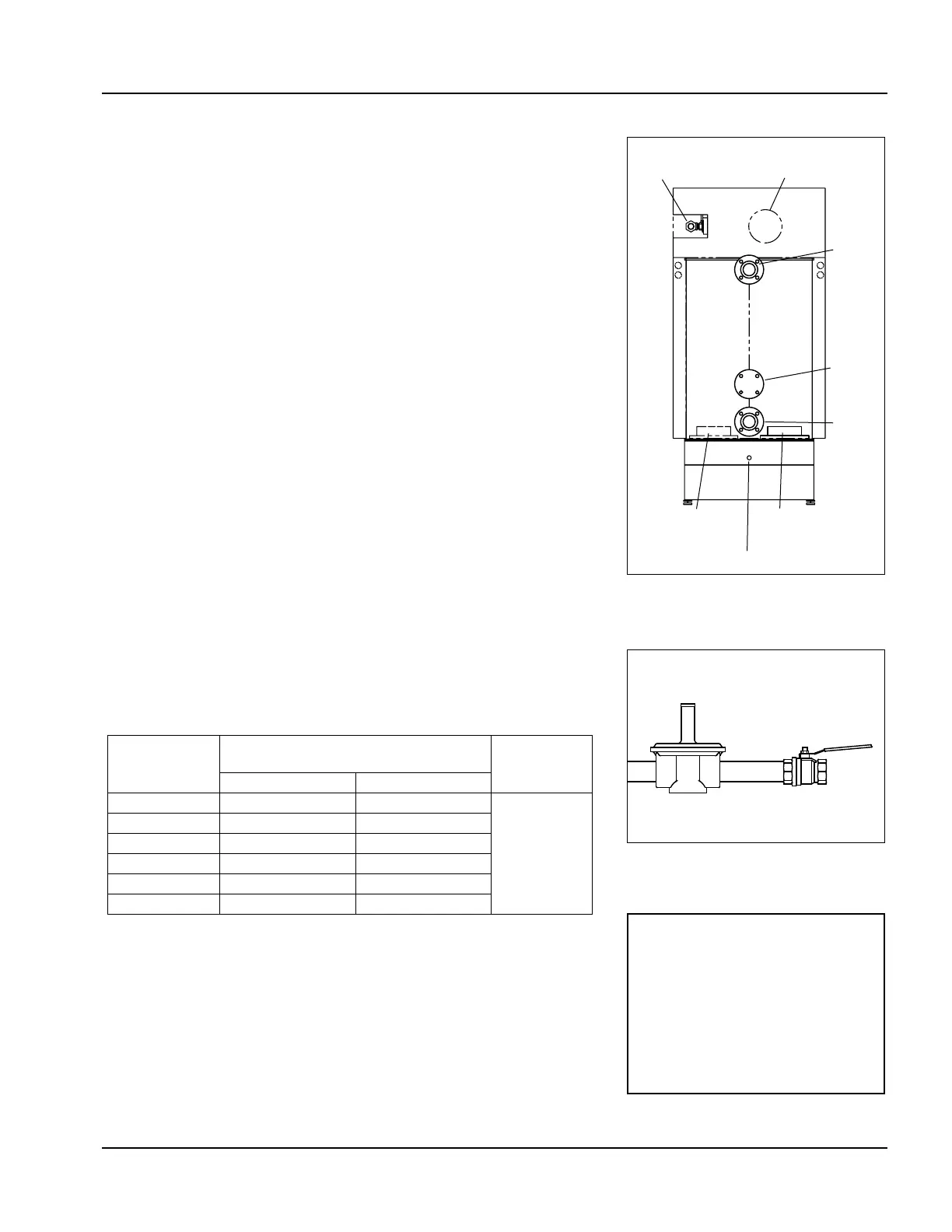

Figure 2-21 Gas Regulator and

Shutoff Valve (typical)

Gas Pressure Regulator

Shutoff Valve

Table 2-3 Model CFC Gas Pressure Requirements

Boiler Model

Minimum pressure required at gas train

connection

Max. pressure

Natural Gas LP Gas

500 7" w.c. 11" w.c.

28” w.c.

750 7" w.c. 11" w.c.

1000 7" w.c. 11" w.c.

1500 10" w.c. 11" w.c.

1800 7" w.c. 11" w.c.

2500 9.5" w.c. 11" w.c.

NOTE: The pressure test port is

located at the gas valve inlet

flange (see Figure 2-22). The

remaining test cocks are for leak

test purposes and should not be

used to measure gas pressure.

Refer to

APPENDIX C - GAS VALVE

INSTALLATION AND MAINTENANCE

for more information.

Loading...

Loading...