Section 2 — Installation

Part No. 750-263 2-29

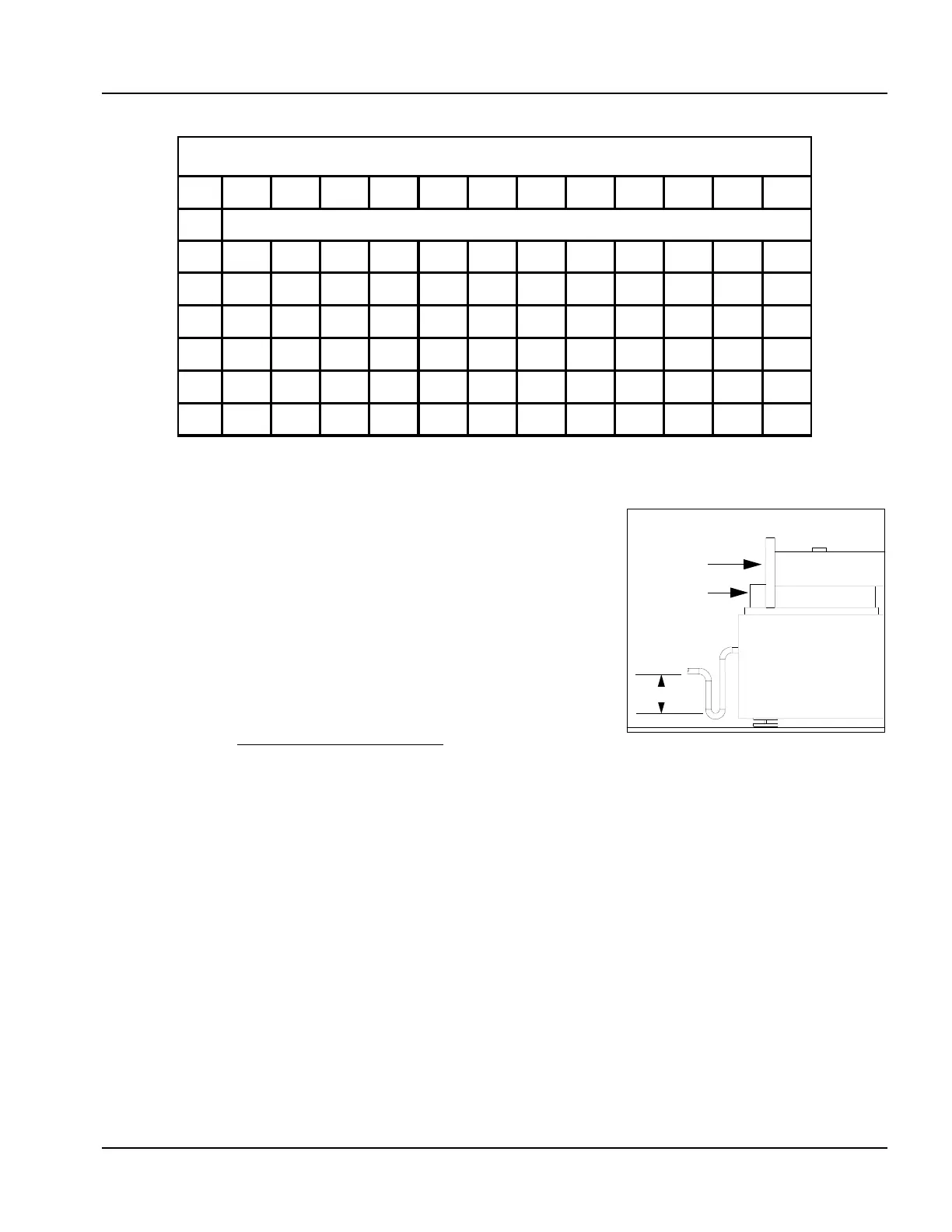

Table 2-13: Maximum flow rate through ClearFire boilers (metric flow rates)

H.CONDENSATE REMOVAL AND TREATMENT

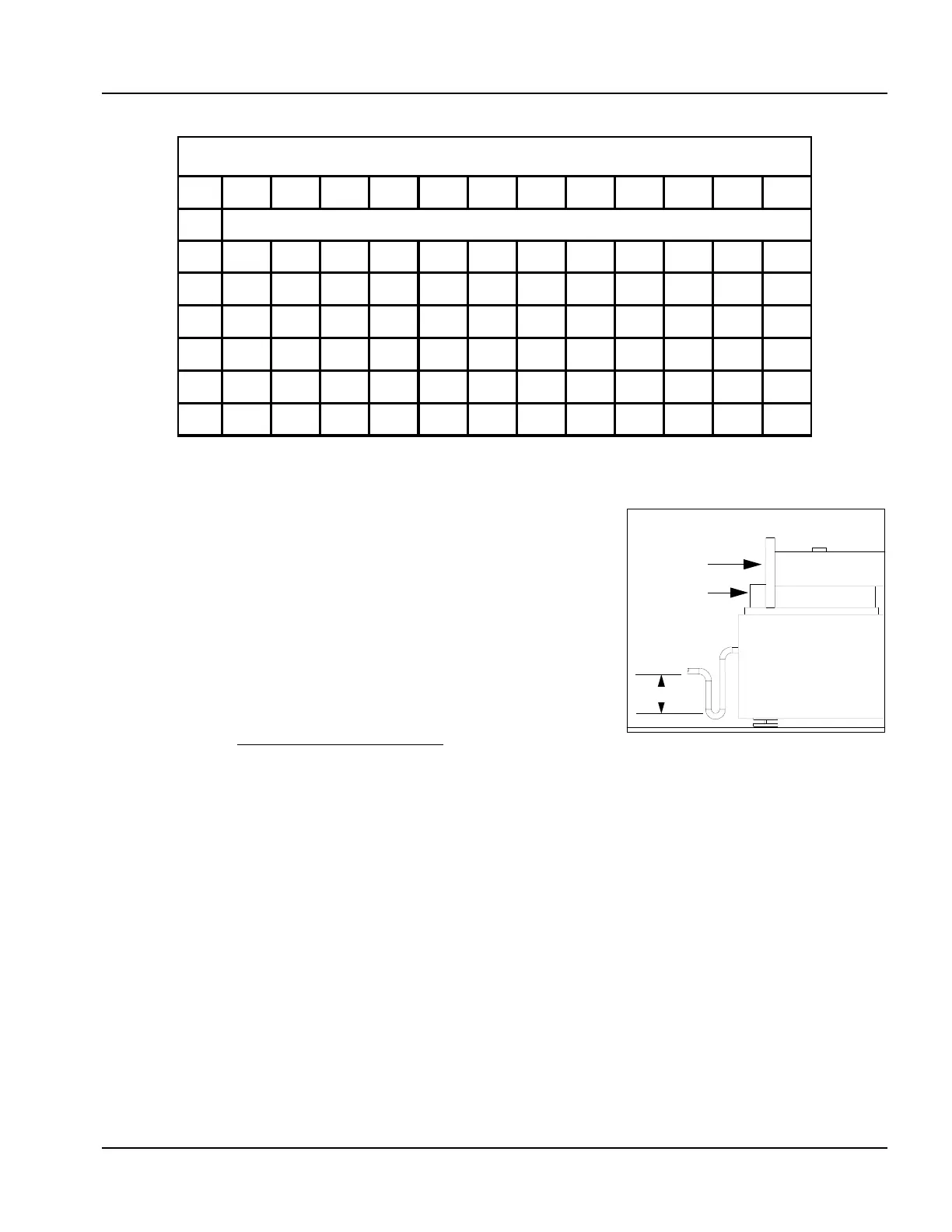

The condensate generated during normal boiler operation must be

removed in accordance with local codes and regulations. The

condensate can be piped to a local treatment system or run into the

optional condensate treatment assembly. When piping condensate

direct to drain, a trap (Figure 2-36) must be installed on the

condensate outlet to prevent discharge of flue gases from the boiler.

When using the treatment tank, a drain trap is included in the tank

assembly and no external trap is required.

The water trap must be filled with water prior to commissioning and

checked or refilled at each required maintenance interval.

Notice

The condensate occurring during operation in both the boiler and the flue

gas pipeline has to be neutralized and piped to a safe drain. The conditions

for the discharge of condensates into public drain systems are determined

by the local authorities and municipalities.

Condensate leaving the boiler normally has a pH of 4-6. The

responsible authority will inform you if a higher pH value is required

for condensate piped to drain. The CFC neutralization system

contains the granulate NEUTRALAT, a natural compound which

acts to increase the pH of the condensate flowing through it. The

neutralization system comprises the plastic neutralization tank with

condensate inlet, makeup valve, drain trap, granulate chamber and

condensate outlet (see Figure 2-38). The system is installed in the

CFC lower collection area.

5 1117222733384550556164

500 21.6 10.9 7.5 5.4 4.3 3.6 2.7 2.5 2.3 2 1.8 1.6

750 29.75 15 10 7.5 6 5 4.3 3.6 3.4 2.9 2.7 2.5

1000 40 20 14 10 8 7 6 5 4.5 4 3.6 3.4

15005929.5201512108.47.56.665.45.2

180080402720161311.310 9 87.36.8

2500 106.7 53.4 36.7 26.8 21.6 17.9 15.2 13.4 11.8 10.9 9.8 8.8

Recommended flow rates relative to temperature drop so as not to exceed boiler output.

System Temperature Drop

0

C

Flow Rate m

3

/hr.

Boiler

Size

Figure 2-36 Flue Gas Trap 6 inch

Minimum Water Column

6”

Return Water In

Stack

Clearfire

Base

Loading...

Loading...