CB FALCON

750-265 30

Setpoint and Hysteresis (Hydronic)

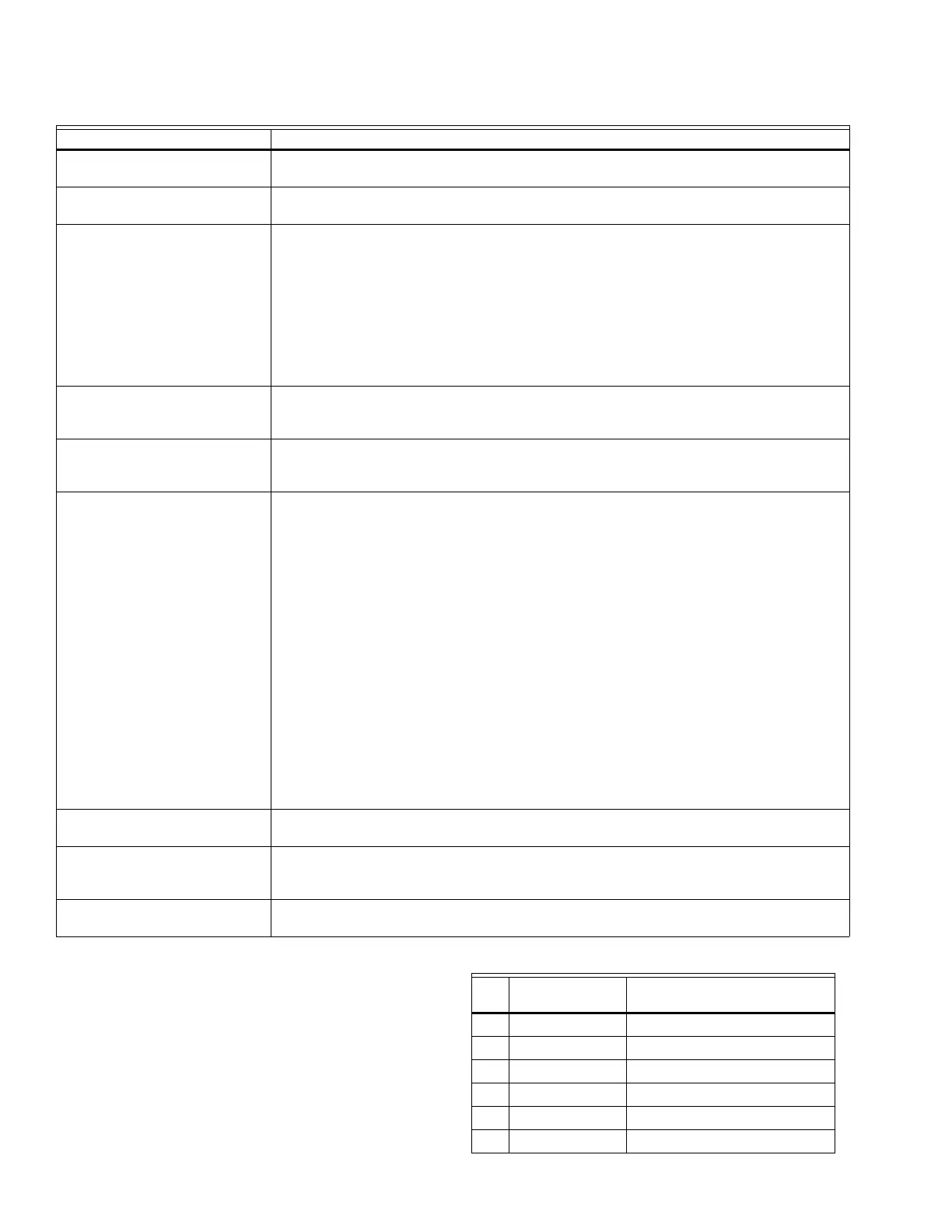

The CH, DHW and LL master each have similar setpoint and

hysteresis functions. The parameters for each are separate

and independent.

Whenever the burner turns on, the turn-off threshold is raised

by 18°F,and then it is decreased in steps. The time of each

step is provided by the hysteresis step time parameter. If the

time (T) is not-zero, then the following schedule is followed

until the off threshold reaches its original value:

Steam pressure setpoint PSI or None

This setpoint is used when the time-of-day input is off.

Steam time-of-day pressure

setpoint

PSI or None

This setpoint is used when the time-of-day input (J10 terminal 2) is on.

Steam Pressure off hysteresis

Steam Pressure on hysteresis

PSI or None

The off hysteresis is added to the setpoint pressure to determine the pressure at which the

demand turns off.

Similarly, the on hysteresis is subtracted from the setpoint to determine the pressure at which

demand turns on.

These may be set to None to indicate that no hysteresis has been defined.

The On and Off hysteresis are adjusted at the time the burner changes from off to on, and

from on to off, as shown in Fig. 12. This gives the PID algorithm some room to be more

aggressive in tracking the load, which can result in overshoot (or undershoot). (see the

Setpoint and Hysteresis section, page 31)

Steam hysteresis step time seconds

Time of each step. A step time of zero - disables this feature. (see the Setpoint and

Hysteresis section, page 31)

Steam P-gain

Steam I-gain

Steam D-gain

0-100

These parameters are the gains applied to the proportional, integral, and differential terms of

the PID equation for the Steam loop.

Steam 4-20mA remote control Disable, Setpoint, Modulation

Disable: When the value is “Disable,” the 4-20mA input via the Header is ignored and both of

the remote control functions are disabled.

Modulation: When the burner is free to modulate during the Run state, the 4-20mA input

from the Header input becomes the modulation source, where 4mA corresponds to the

Minimum modulation rate and 20mA corresponds to the Maximum modulation rate. All other

behavior remains as it was; the setpoint and the on/off hysteresis values are still used to

determine the burner-on and burner-off thresholds, and the TOD will still affect the burner-on

and burner-off thresholds, if this is enabled.

When the 4-20mA input is faulty (open, shorted, out of range, etc.) the control issues an alert

and reverts to using PID output for modulation, as if the 4-20mA function were disabled.

Setpoint: This parameter disables the CH outdoor reset function and the setpoint is provided

using a linear interpolation of the 4-20mA input value within a range:

• Either the CH pressure setpoint or the CH TOD pressure setpoint provides the setpoint for

the 20mA, depending on the state of the TOD input, and the CH minimum pressure

provides the setpoint for 4mA.

When the 4-20mA input is faulty (open, shorted, out of range, etc.) the control issues an alert

and reverts to using:

• For steam either the CH pressure setpoint or the CH TOD pressure setpoint, depending

on the state of the TOD input.

Steam 4-20mA remote control

hysteresis

n.n mA

Provides a hysteresis filter for the 4-20ma remote control input.

CH minimum pressure PSI

This parameter provides the minimum steam pressure used to calculate the 4-20mA control

setpoint for 4mA.

20 mA CH pressure PSI or None

Establishes the pressures for the end points of the 4-20 mA inputs

Table 10. Central Heating Steam Parameters. (Continued)

Parameter Comment

Step

Time since turn-

on Hydronic Turn-off threshold

1

0 <=

time <1T

Setpoint + Off hysteresis + 18°F

2

1T <=time <2T

Setpoint + Off hysteresis + 8°F

3

2T <= time <3T

Setpoint + Off hysteresis + 6°F

4

3T <=time <4T

Setpoint + Off hysteresis + 4°F

5

4T <=time <5T

Setpoint + Off hysteresis + 2°F

6

5 <= time

Setpoint

Loading...

Loading...