CB FALCON

750-265 52

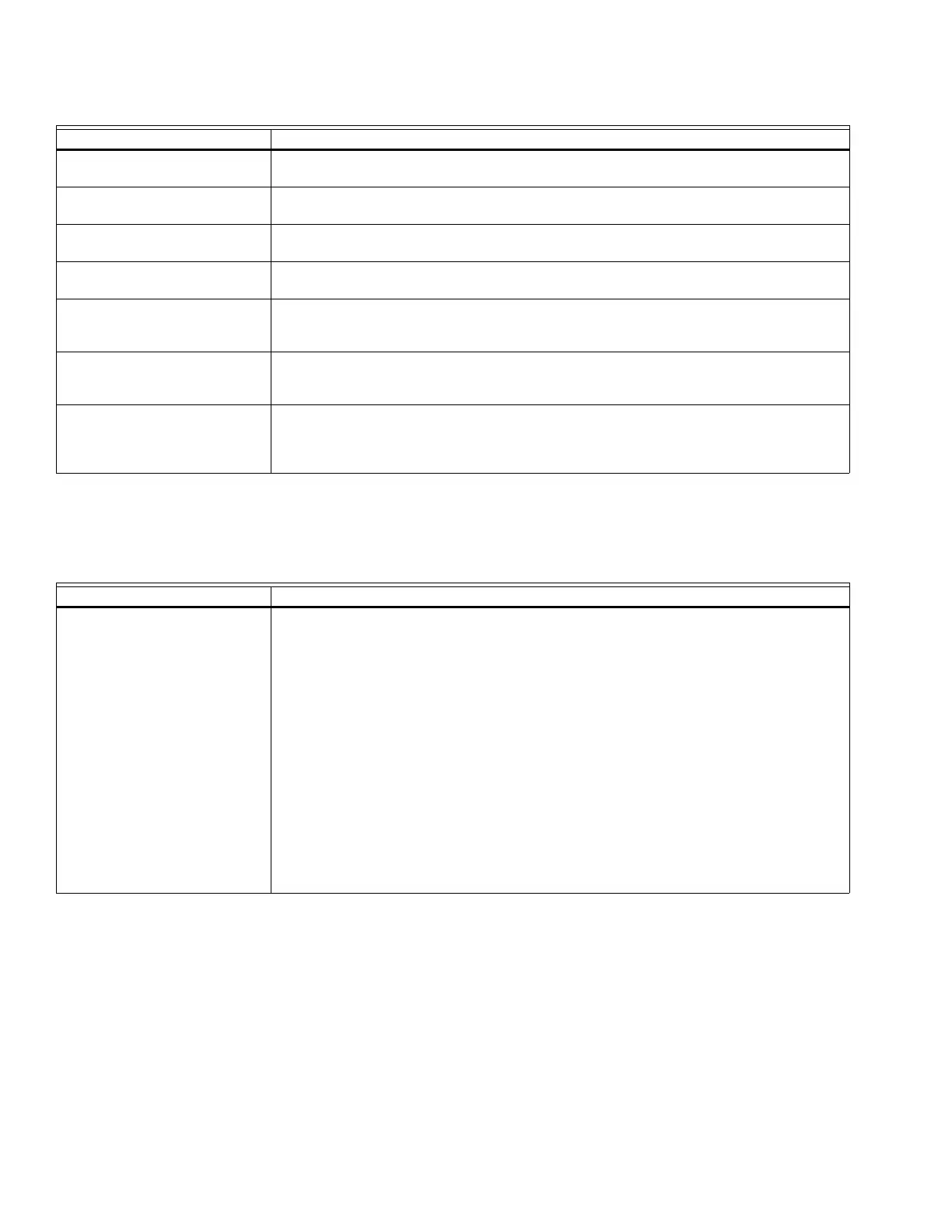

Analog Modulation Parameters

These parameters are used only when 4-20mA or 0-10V is selected for modulation output.

PWM frequency 1000Hz, 2000Hz, 3000Hz, 4000Hz,

This parameter provides the frequency used by the PWM output to control the fan.

Pulses per revolution 0-10

Typically is the number of sensors that the fan contains.

Fan gain up 0-100

This is the gain for speeding up the fan.

Fan gain down 0-100

This is the gain for slowing down the fan.

Speed up ramp RPM per second

Whenever the burner is firing, the fan will be commanded to increase its RPM no faster than

the rate provided by this parameter.

Slow down ramp RPM per second

Whenever the burner is firing, the fan will be commanded to decrease its RPM no faster than

the rate provided by this parameter.

Fan min duty cycle duty%

The fan modulation output will never send a duty cycle lower than this threshold, except for a

0% duty cycle to turn the fan off.

This can be used to limit the minimum PWM to a level that prevents stalling of the fan.

Table 28. Fan Speed Modulation Parameters.

Parameter Comment

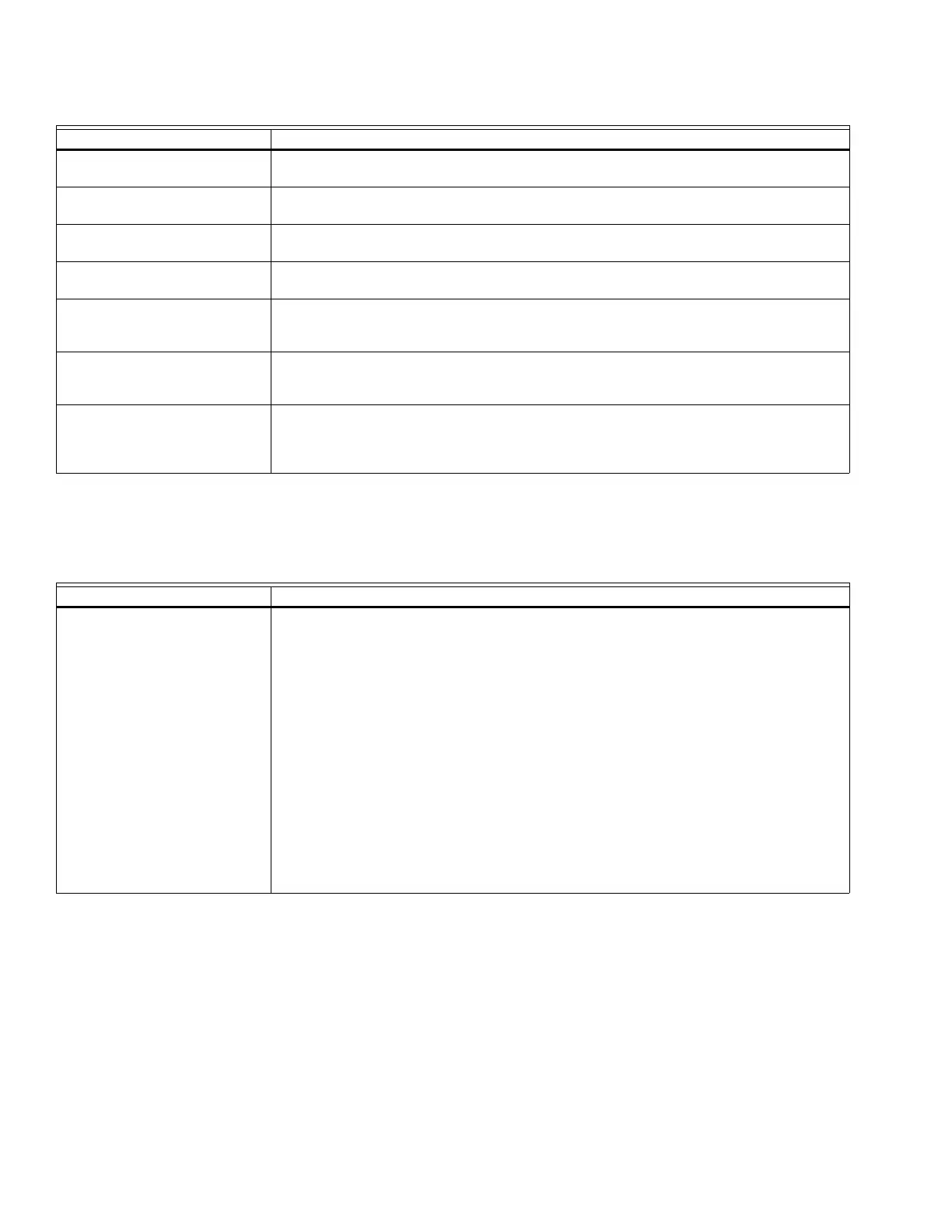

Analog output hysteresis n

This parameter adjusts the amount of hysteresis applied to the PID output when a non-PWM

modulation is selected. The “n” value determines how much the PID is required to change in

a new direction before the output will change.

This is somewhat experimental, although simulation shows this technique provides better

response and also better control of motor reversals than a deadband.

A typical range is 0 (disabled) to 10, although higher values are allowed. The amount of PID

change required to change direction is computed as:

n/10 * Pgain * P scaler

Background: The granularity of temperature measurement in the Falcon is 0.1C, which is

represented internally as an integer (e.g. C * 10). Thus if the temperature changes by the

smallest measurable amount (e.g. 1 count), the P term of the PID output will contribute a

change of 1*Pgain * P scaler, to the total PID output. The parameter thus allows some

fraction of this change to be the threshold for changing direction, e.g. “n” = 5 means0.5 or half

of this amount of change would be needed to change direction. If the Igain is zero then using

any value of “n” less than 10 makes no difference; however when Igain is non-zero it also

contributes to the PID output, so smaller amounts of hysteresis make sense. Experimentally,

values of between 5 to 10 seem to work well.

Table 27. Fan Speed Modulation Parameters. (Continued)

Parameter Comment

Loading...

Loading...