ClimateMaster Water-Source Heat Pumps

76

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility

®

Compact (TC) Series

Rev.: July 7, 2020

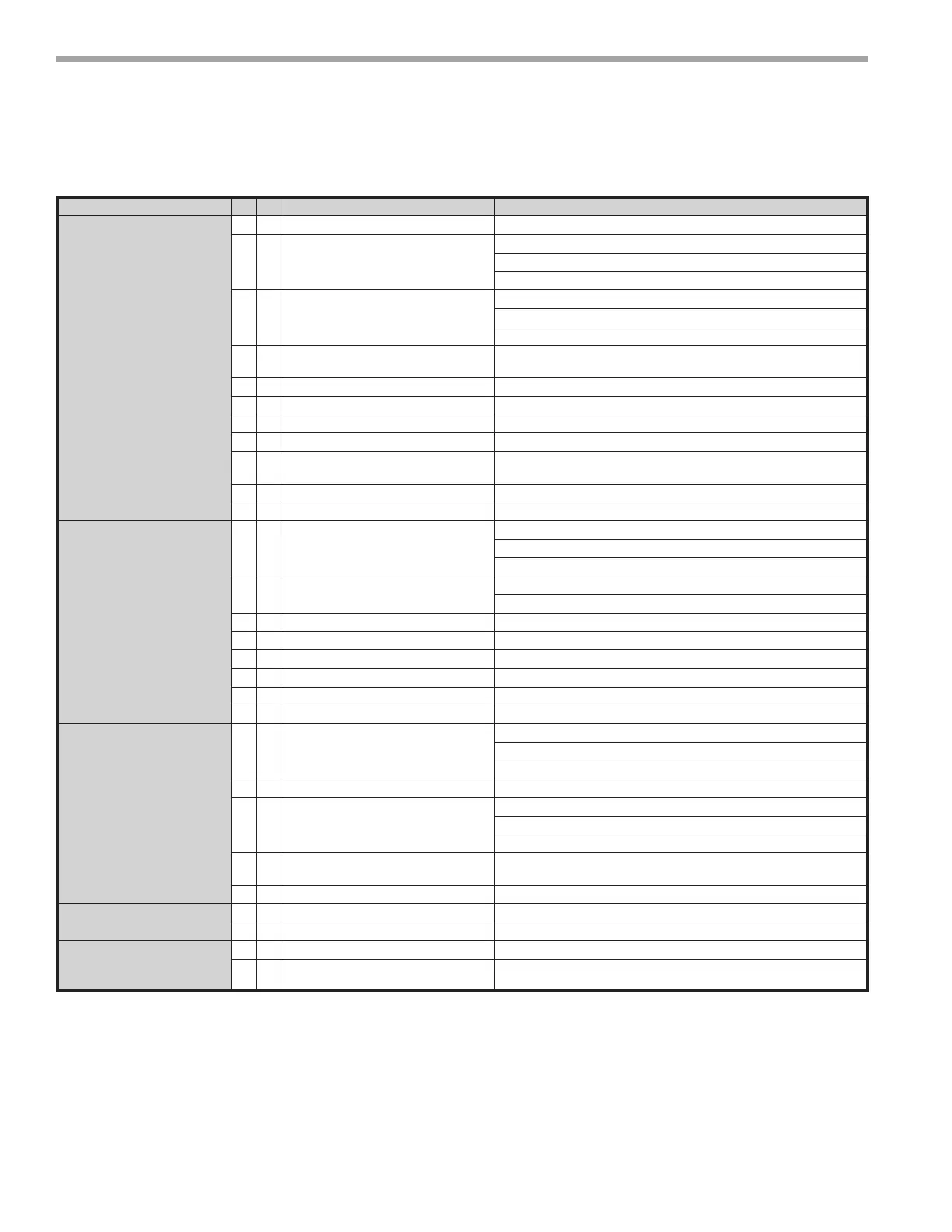

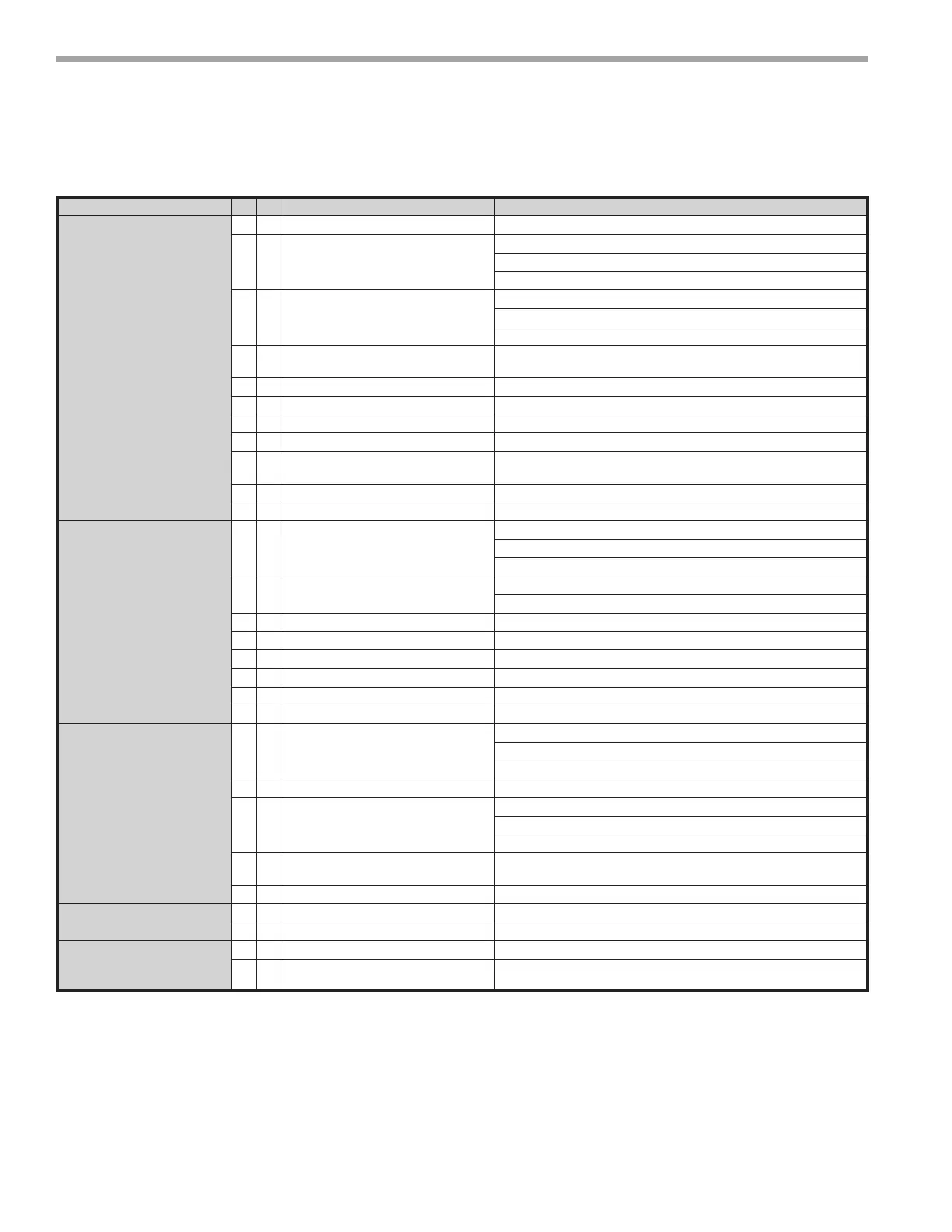

Performance Troubleshooting

Performance Troubleshooting Htg Clg Possible Cause Solution

Insufcient capacity/ Not

cooling or heating

X X Dirty lter Replace or clean.

X Reduced or no air ow in heating

Check for dirty air lter and clean or replace.

Check fan motor operation and airow restrictions.

Too high of external static. Check static vs. blower table.

X Reduced or no air ow in cooling

Check for dirty air lter and clean or replace.

Check fan motor operation and airow restrictions.

Too high of external static. Check static vs. blower table.

X X Leaky duct work

Check supply and return air temperatures at the unit and at distant duct

registers if signicantly different, duct leaks are present.

X X Low refrigerant charge Check superheat and subcooling per chart.

X X Restricted metering device Check superheat and subcooling per chart. Replace.

X Defective reversing valve Perform RV touch test.

X X Thermostat improperly located Check location and for air drafts behind stat.

X X Unit undersized

Recheck loads & sizing. Check sensible clg. load and heat pump

capacity.

X X Scaling in water heat exchanger Perform scaling check and clean if necessary.

X X Inlet water too hot or too cold Check load, loop sizing, loop backll, ground moisture.

High Head Pressure

X Reduced or no air ow in heating

Check for dirty air lter and clean or replace.

Check fan motor operation and air ow restrictions.

Too high of external static. Check static vs. blower table.

X Reduced or no water ow in cooling

Check pump operation or valve operation/setting.

Check water ow. Adjust to proper ow rate.

X Inlet water too hot Check load, loop sizing, loop backll, ground moisture.

X Air temperature out of range in heating Bring return air temperature within design parameters.

X Scaling in water heat exchanger Perform scaling check and clean if necessary.

X X Unit overcharged Check superheat and subcooling. Re-weigh in charge.

X X Non-condensables in system Vacuum system and re-weigh in charge.

X X Restricted metering device. Check superheat and subcooling per chart. Replace.

Low Suction Pressure

X Reduced water ow in heating.

Check pump operation or water valve operation/setting.

Plugged strainer or lter. Clean or replace.

Check water ow. Adjust to proper ow rate.

X Water temperature out of range. Bring water temperature within design parameters.

X Reduced air ow in cooling.

Check for dirty air lter and clean or replace.

Check fan motor operation and air ow restrictions.

Too high of external static. Check static vs. blower table.

X Air temperature out of range

Too much cold vent air? Bring entering air temperature within design

parameters.

X X Insufcient charge Check for refrigerant leaks.

Low Discharge Air

Temperature in Heating

X Too high of air ow Check fan motor speed selection and air ow chart.

X Poor performance See ‘Insufcient Capacity’

High humidity

X Too high of air ow Check fan motor speed selection and airow chart.

X Unit oversized

Recheck loads & sizing. Check sensible clg load and heat pump

capacity.

Loading...

Loading...