Page 36 BB4500-BB5000 Operating Manual

onto the bar. This gives you multiple positions of the tool bit. CLIMAX has

designed these so that you can use a variety of tool bit types.

The cutting speed is primarily determined by the hardness of the metal being

machined and the type of tool bit used. Other factors include the power source,

feed and depth of cut, and cooling medium being used.

Generally, carbide cutting tools operate at higher RPM than high-speed steel

(HSS) tools. For more information, see Section 4.2 on page 52.

3.3.2.1 Placing the tool bit into the bar

Do the following to insert the tool

bit into the bar:

1. Retract the set screw that is

located 90° from the tool

slot.

2. Insert the tool bit into the

tool slot so that it slides

freely into the broached

hole (see Figure 3-7).

3. Clamp the tool bit into

place by re-tightening the

set screw.

4. Set the tool bit to the cor-

rect radius for cutting the

required diameter. There

are multiple ways to set the

desired radius (for instance,

using a bore measuring tool).

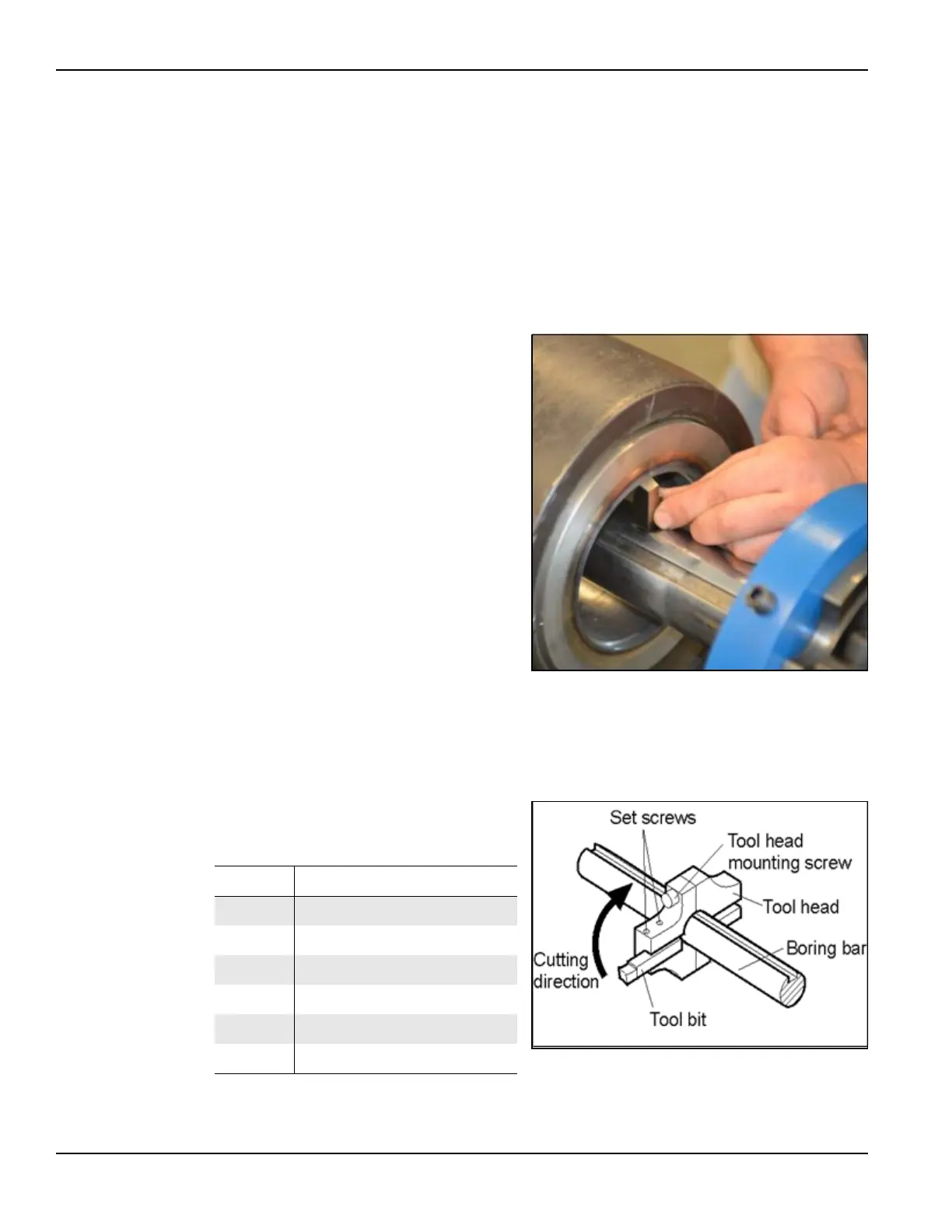

3.3.2.2 Placing the tool head onto the boring head

FIGURE 3-7. INSERTING THE TOOL BIT

TABLE 3-4. TOOL HEAD SETUP IDENTIFICATION

Number Component

1 Set screws

2 Tool head mounting screw

3 Tool head

4 Boring bar

5 Tool bit

6 Cutting direction

FIGURE 3-8. TOOL HEAD SETUP

Loading...

Loading...